Micro high-pressure two-position two-way solenoid valve

A two-position, two-way, solenoid valve technology, used in lift valves, valve details, valve devices, etc., can solve the problem of low sealing reliability of high-pressure solenoid valves, large quality and volume of high-pressure solenoid valves, and inability to meet aerospace high-pressure supply. Gas system components design requirements and other issues, to achieve the effect of reducing quality, long-lasting work, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

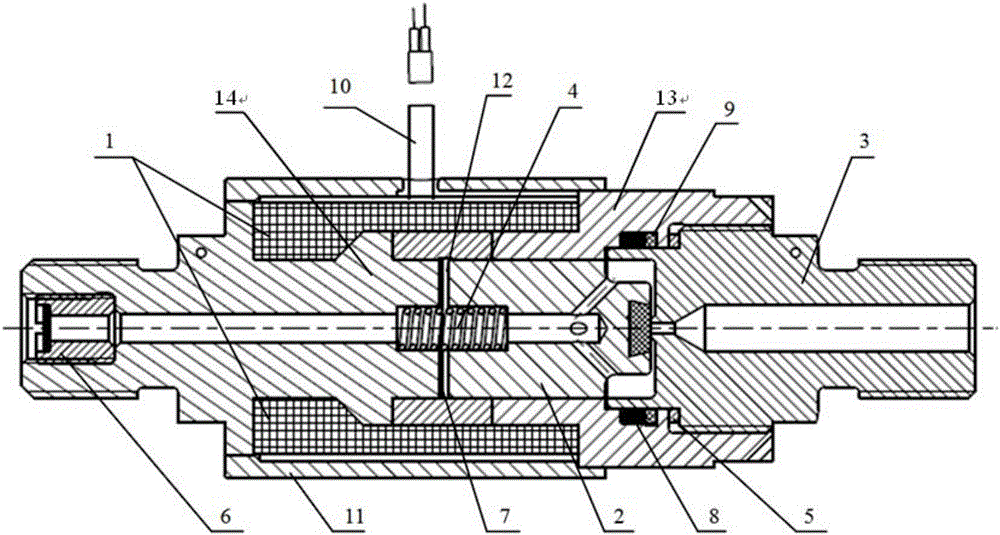

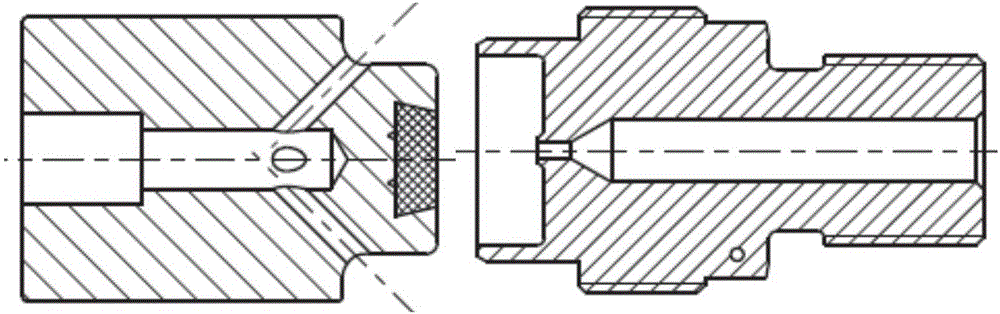

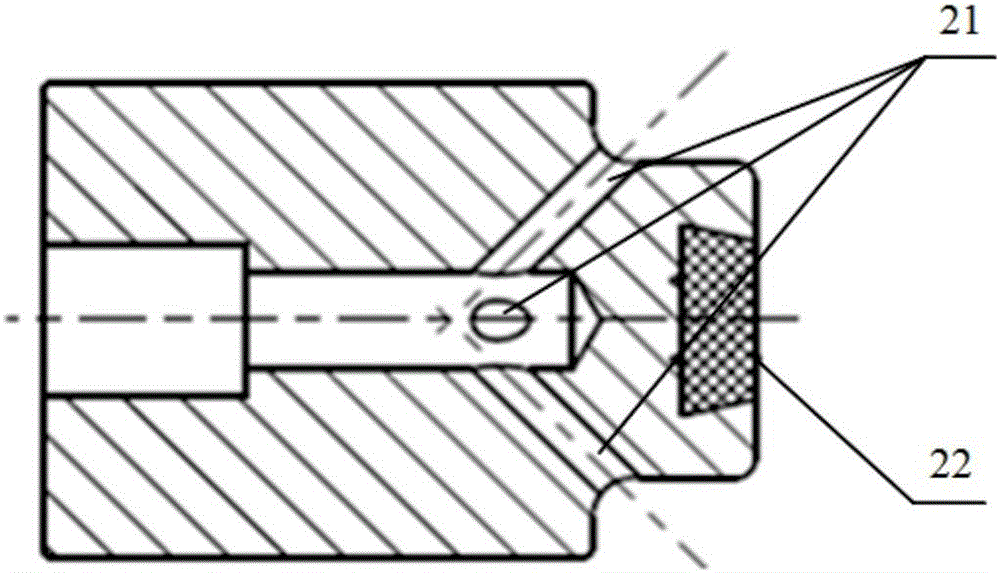

[0020] like figure 1 As shown, it is the structure of the miniature high-pressure two-position two-way solenoid valve of the present invention, which mainly consists of the valve core 2 in the valve body 13, the coil assembly 1, the valve body 13, the valve seat 3, the spring 4 exerting force on the valve core, It is composed of a magnetic isolation spacer 7 , a wire 10 drawn from the coil assembly 1 , and a casing 11 . Wherein coil assembly 1 adopts the irregular coil window structure combining polygon and rectangle, and this example adopts the window structure combining trapezoid and rectangle (see figure 1 The profile of the middle coil), the redundant iron stop part in the magnetic circuit of the electromagnet is designed as a coil window, the space occupied by the coil window of this irregular structure will not affect the magnetic circuit, but the internal space is fully utilized to ensure the electromagnetic When the number of coil turns required for the reliable opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com