Flexible battery and preparation method thereof

A flexible battery and electrode technology, used in secondary battery manufacturing, secondary batteries, lithium batteries, etc., can solve problems such as inability to fill batteries and short battery life, and achieve the effect of improving lifespan and bending performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

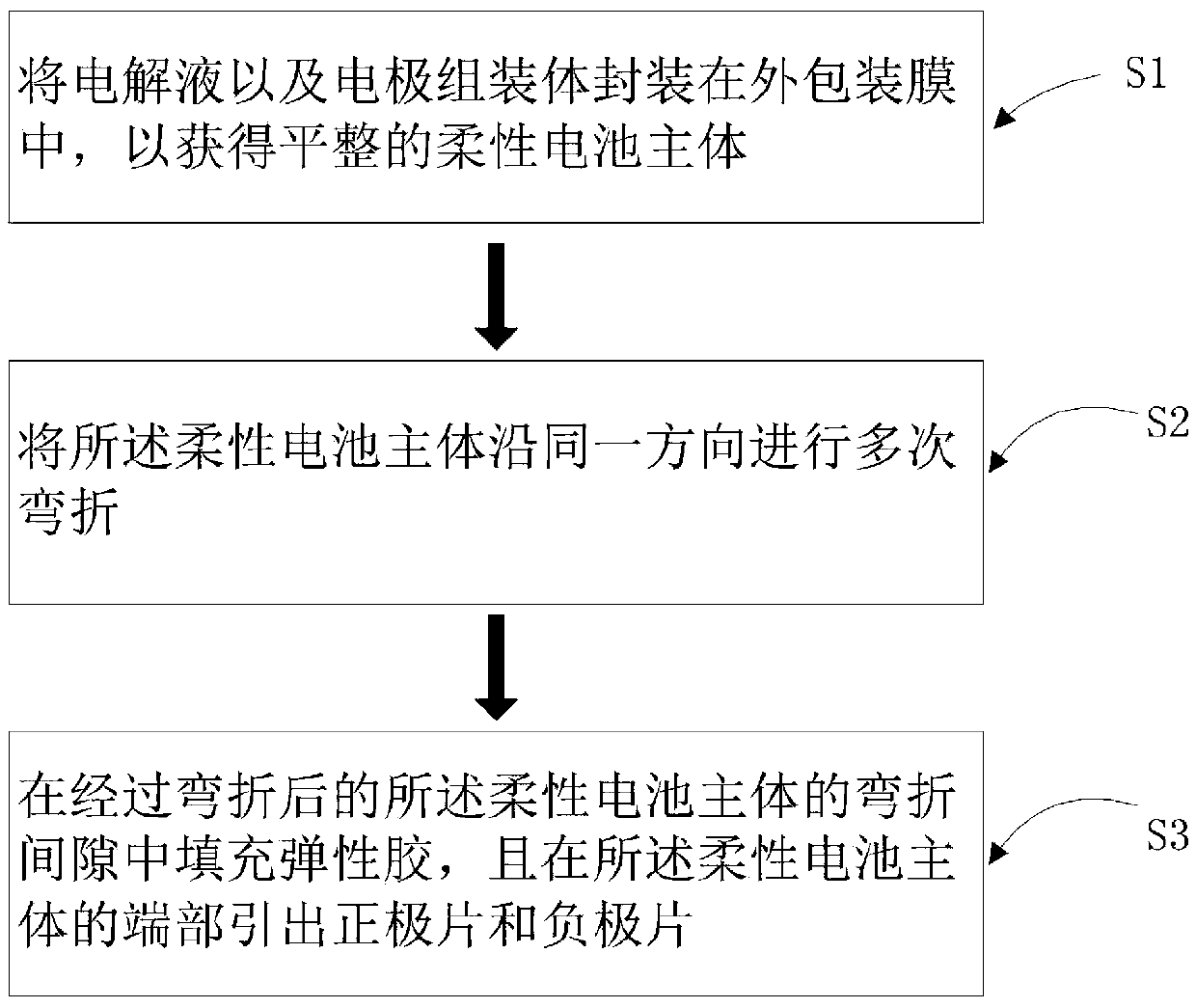

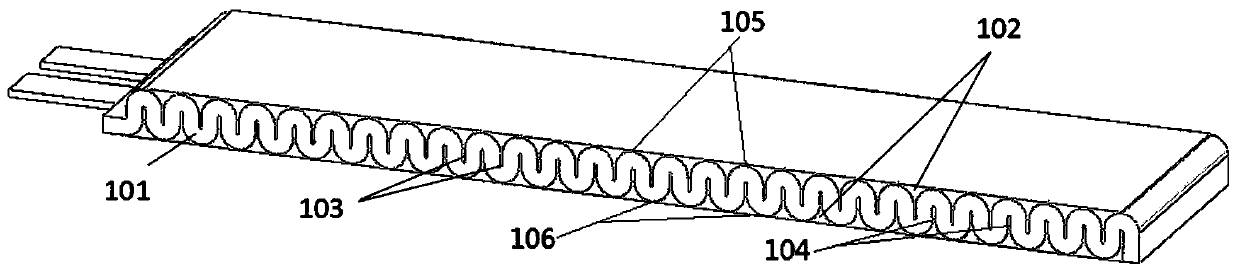

[0034] see Figure 1-12 , an embodiment of the present invention provides a method for preparing a flexible battery, comprising the following steps: S1, packaging the electrolyte and the electrode assembly in an outer packaging film to obtain a flat flexible battery body 101; S2, packaging the flexible battery body 101 is bent multiple times in the same direction; S3, filling the elastic glue 102 in the bending gap of the flexible battery body 101 after bending, and leading out the positive electrode sheet and the negative electrode at the end of the flexible battery body 101 piece. In this embodiment, the flexible battery main body 101 prepared in step S1 is the same as the existing flexible battery main body 101, and is flat and long. The next step is the key point of this embodiment. The flat The elongated flexible battery main body 101 is bent multiple times along the same direction to form multiple bending points. At this time, the preparation of the flexible battery has...

specific Embodiment

[0036] As an optimization scheme of the embodiment of the present invention, please refer to figure 2 , in the step S2, the specific bending method is: take one side of the flexible battery main body 101 as the starting side, and end with the side of the flexible battery main body 101 opposite to the starting side side, along the direction from the start side to the end side, start to bend the flexible battery body 101 in a serpentine form at the start side until it reaches the end of the flexible battery body 101 Stop when terminating side. In this embodiment, the flexible battery main body 101 is first defined as a long strip, and the bending process is performed in a serpentine form, the bending is continuous bending, and the bending direction is the length direction of the flexible battery main body 101, and finally After the bending is completed, the first bending points 105 on the upper side of the flexible battery body 101 are peaks, and the second bending points 106 ...

Embodiment 2

[0046] The content in this embodiment and the first embodiment can be referred to each other. see Figure 2-12 , an embodiment of the present invention provides a flexible battery, including a flexible battery body 101, the flexible battery body 101 includes an electrolyte, an electrode assembly, and an outer packaging film for encapsulating the electrolyte and the electrode assembly, so The flexible battery body 101 is bent sequentially to form a plurality of bending points, and there is a bending gap between two adjacent bending points on the same side, and elastic glue 102 is filled in each bending gap. In this embodiment, in this embodiment, initially the flexible battery body 101 is flat and long like the existing flexible battery body 101, and then the flat and long flexible battery body 101 is Multiple bendings in the same direction will form multiple bending points. At this time, the preparation of the flexible battery has been half completed. Through these bending st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com