Copper wire circulating heating annealing furnace

A cycle heating and annealing furnace technology, applied in heat treatment furnaces, furnaces, furnace types, etc., can solve the problems of easy oxidation of copper wires and high pressure of annealing furnaces, and achieve the effects of stable rotation, cost saving, and reduced deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

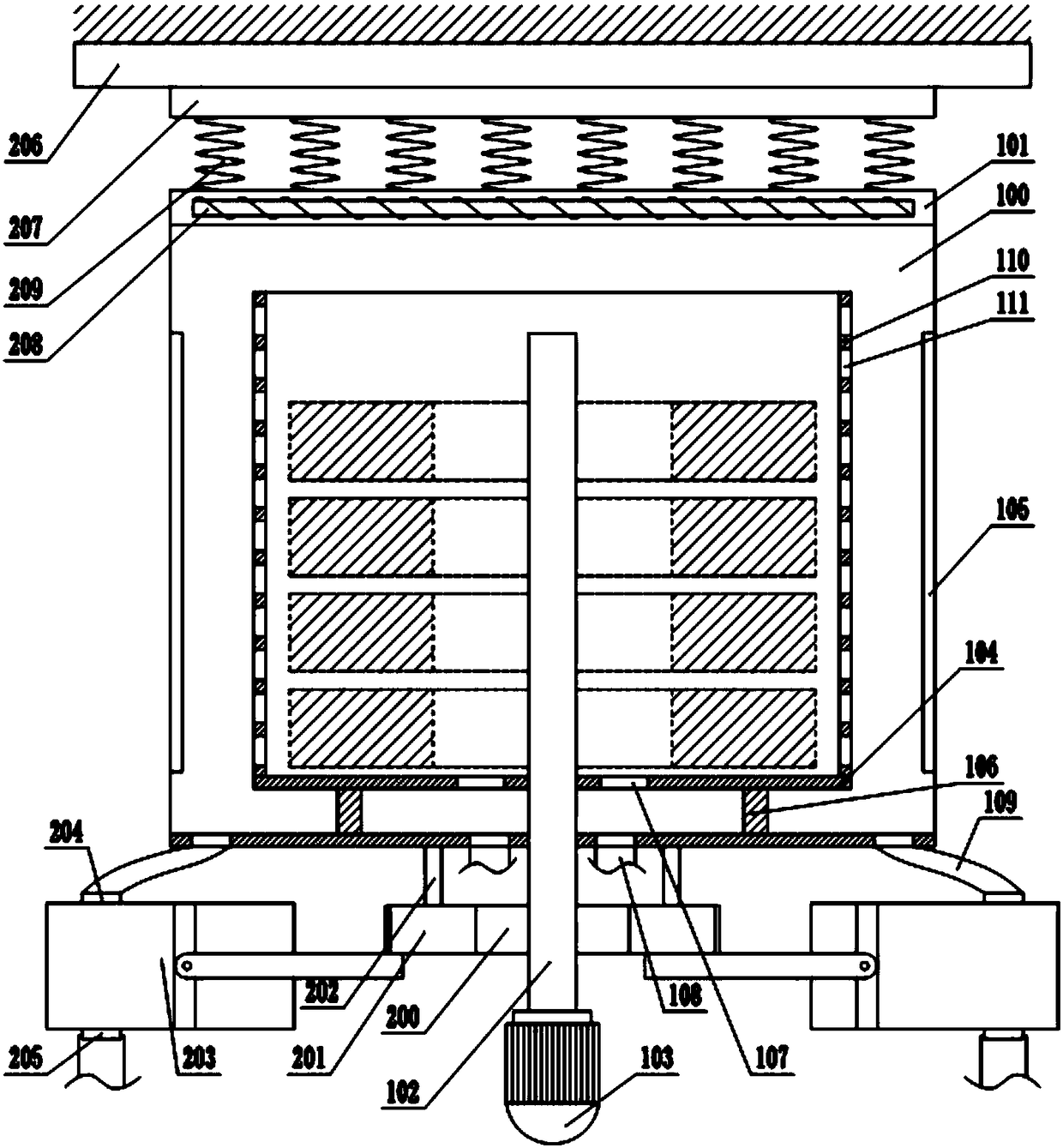

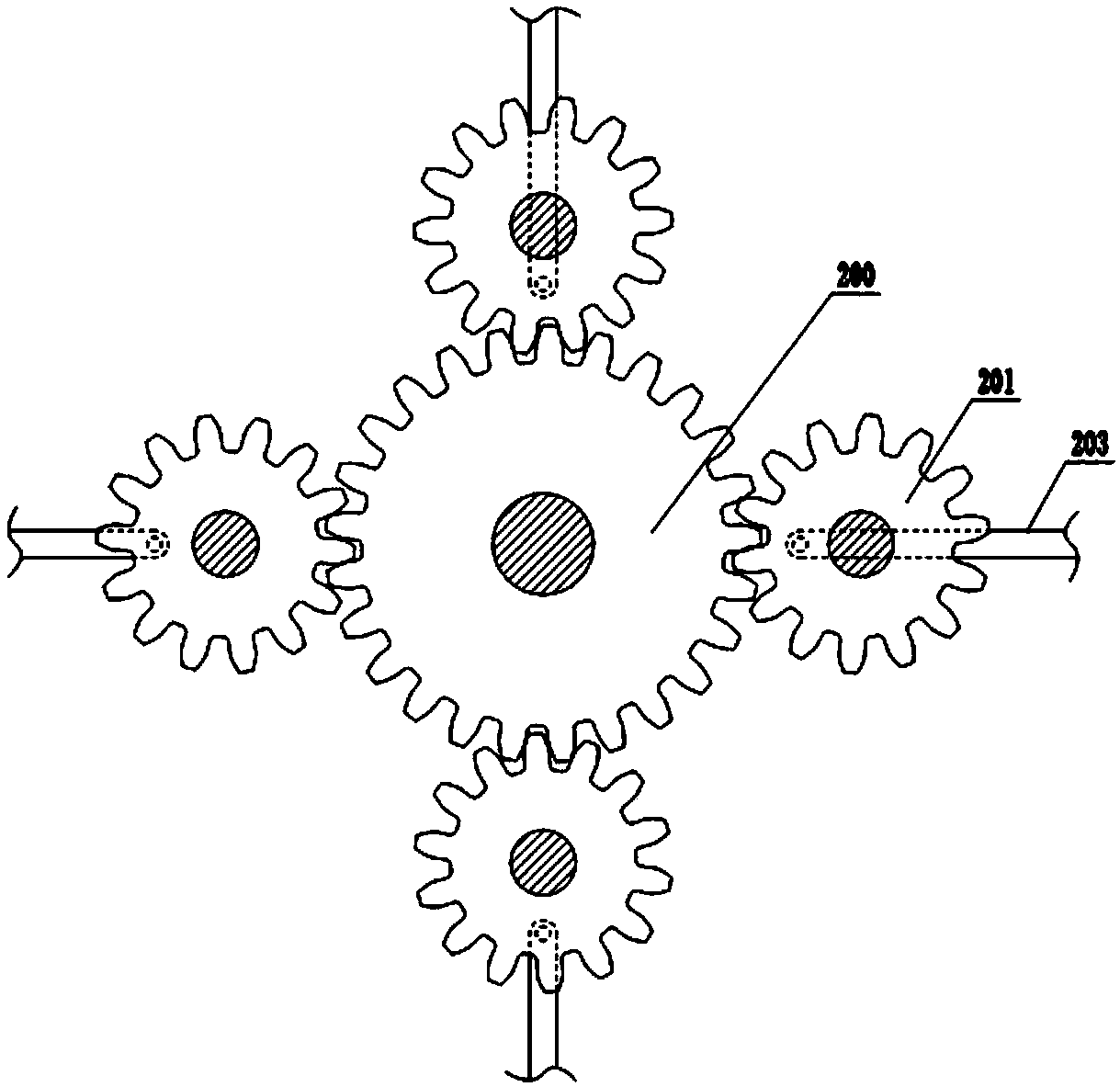

[0021] The reference signs in the accompanying drawings of the description include: annealing box 100, cover body 101, rotating shaft 102, motor 103, turntable 104, heating wire 105, support cylinder 106, hot air hole 107, air inlet pipe 108, air outlet pipe 109, rotary Barrel 110, wind hole 111, driving gear 200, driven gear 201, gear shaft 202, cylinder 203, intake check valve 204, exhaust check valve 205, upper cover 206, permanent magnet 207, electromagnet 208, spring 209 .

[0022] Such as figure 1 As shown, the present invention discloses a copper wire circulation heating annealing furnace, including an annealing box 100, the upper end of the annealing box 100 is sealed with a cover 101, and the bottom of the annealing box 100 is rotatably connected with a rotating shaft 102 driven by a motor 103. The rotating shaft 102 inside the annealing box 100 is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com