High-performance high-entropy alloy and processing method thereof

A high-entropy alloy, high-performance technology, applied in the field of composition design and processing technology of high-performance alloys, can solve problems such as insufficient room temperature strength, and achieve the effects of strong economy, reasonable content and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1 (Fe 40 mn 40 co 10 Cr 10 )

[0040] 1) According to the nominal composition (Fe 40 mn 40 co 10 Cr 10 ) 97.8 C 2.2 The composition is batched, with a total mass of about 200g, smelted under a vacuum electric arc furnace, and smelted four times to obtain an as-cast alloy with a grain size of about 100μm;

[0041] 2) Under this method, a single 200g smelting can ensure the uniformity of composition and structure, and the tensile strength of the material is about 650MPa, which meets the service requirements and can be used directly without subsequent treatment;

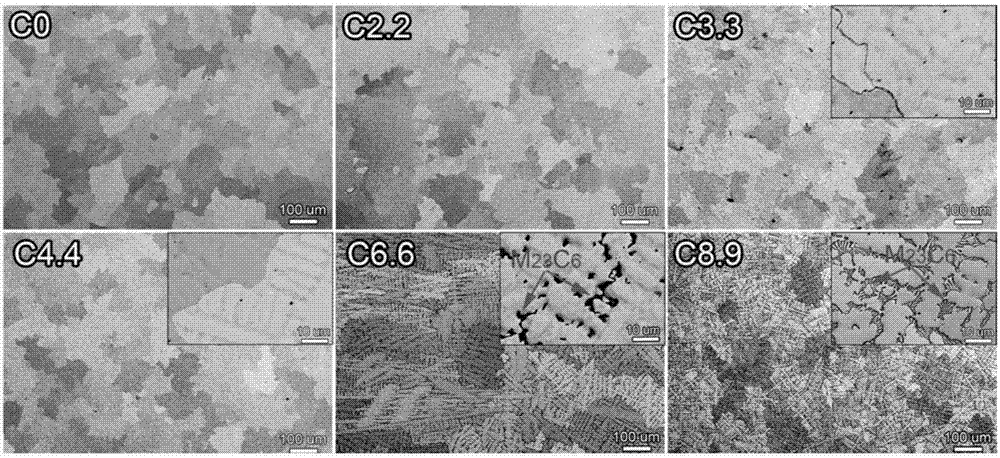

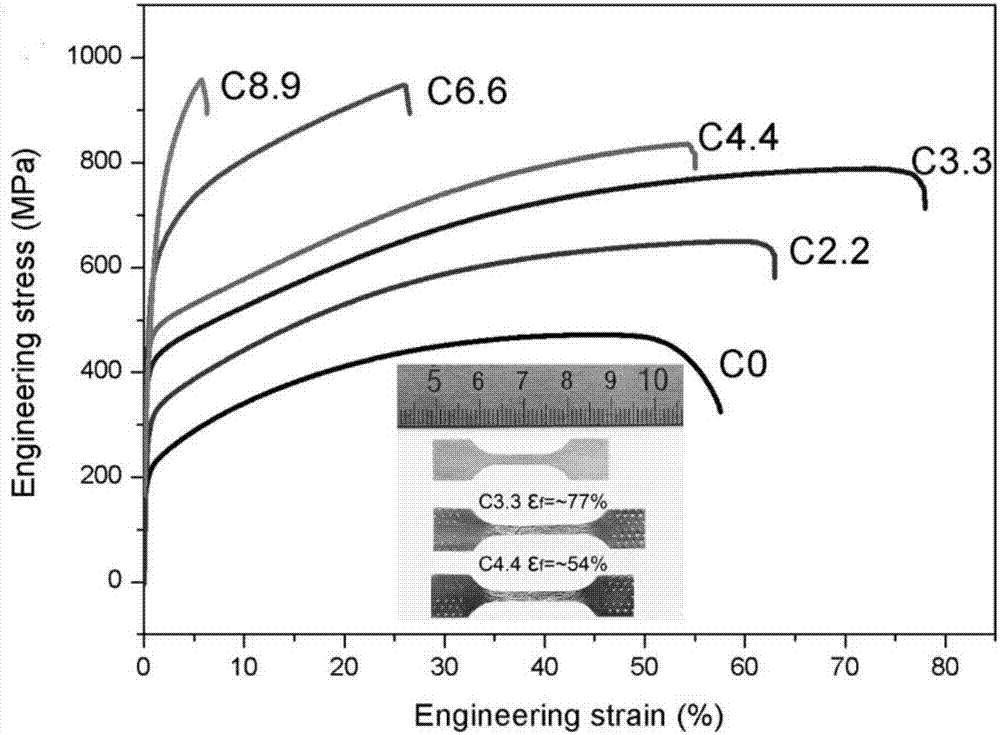

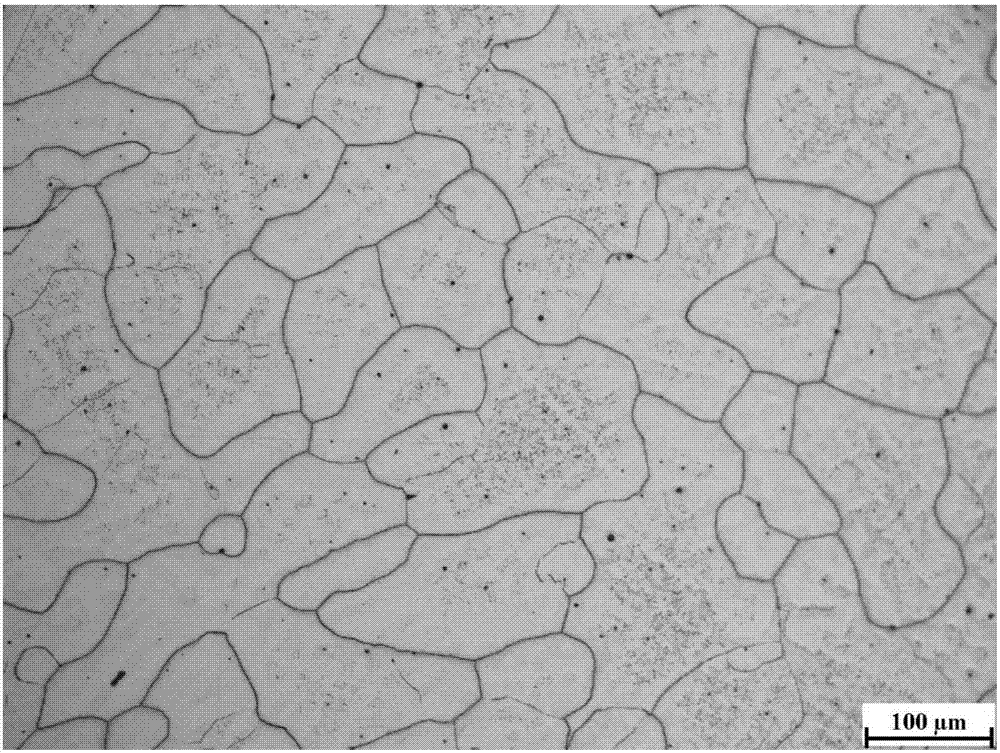

[0042] The ingot structure of the alloy of this composition after smelting is as follows: figure 1 As shown, the average grain size is about 100 μm, and the tensile curve of the ingot of this composition is shown as figure 2 As shown in C2.2, it can be seen that the carbon-free Fe prepared by the same method 40 mn 40 co 10 Cr 10 Compared with the alloy (curve C0), its strength and plasticity...

Embodiment 2

[0043] Example 2 (Fe 40 mn 40 co 10 Cr 10 )

[0044] 1) According to the nominal composition (Fe 40 mn 40 co 10 Cr 10 ) 96.7 C 3.3 The composition is batched, with a total mass of about 200g, smelted under a vacuum electric arc furnace, and smelted four times to obtain an as-cast alloy with a grain size of about 100μm;

[0045] 2) Under this method, a single 200g smelting can ensure the uniformity of composition and structure, and the tensile strength of the material is about 787MPa, which meets the service requirements and can be used directly without subsequent treatment;

[0046] The ingot structure of the alloy of this composition after smelting is as follows: figure 1 As shown, the average grain size is about 100 μm, and the tensile curve of the ingot of this composition is shown as figure 2 As shown in C3.3, it can be seen that the carbon-free Fe prepared by the same method 40 mn 40 co 10 Cr 10 Compared with the alloy (curve C0), its strength and plastici...

Embodiment 3

[0047] Embodiment 3 (Fe 40 mn 40 co 10 Cr 10 )

[0048] 1) According to the nominal composition (Fe 40 mn 40 co 10 Cr 10 ) 95.6 C 4.4 The composition is batched, with a total mass of about 200g, smelted under a vacuum electric arc furnace, and smelted four times to obtain an as-cast alloy with a grain size of about 100μm;

[0049] 2) Under this method, a single 200g smelting can ensure the uniformity of composition and structure, and the tensile strength of the material is about 836MPa, which meets the service requirements and can be used directly without subsequent treatment;

[0050] The ingot structure of the alloy of this composition after smelting is as follows: figure 1 As shown, the average grain size is about 100 μm, and the tensile curve of the ingot of this composition is shown as figure 2 As shown in C4.4, it can be seen that the carbon-free Fe prepared by the same method 40 mn 40 co 10 Cr 10 Compared with the alloy (curve C0), its strength and plast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com