High-strength high-plasticity shape memory steel and preparation method thereof

A high-strength, high-plasticity technology, applied in the field of iron-based shape memory alloy materials, can solve the problems of not considering the influence of shape memory effect, less attention to the mechanical properties of alloys, and a small improvement range, so as to achieve a simple and controllable preparation process , excellent shape memory effect, and the effect of reducing cost and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

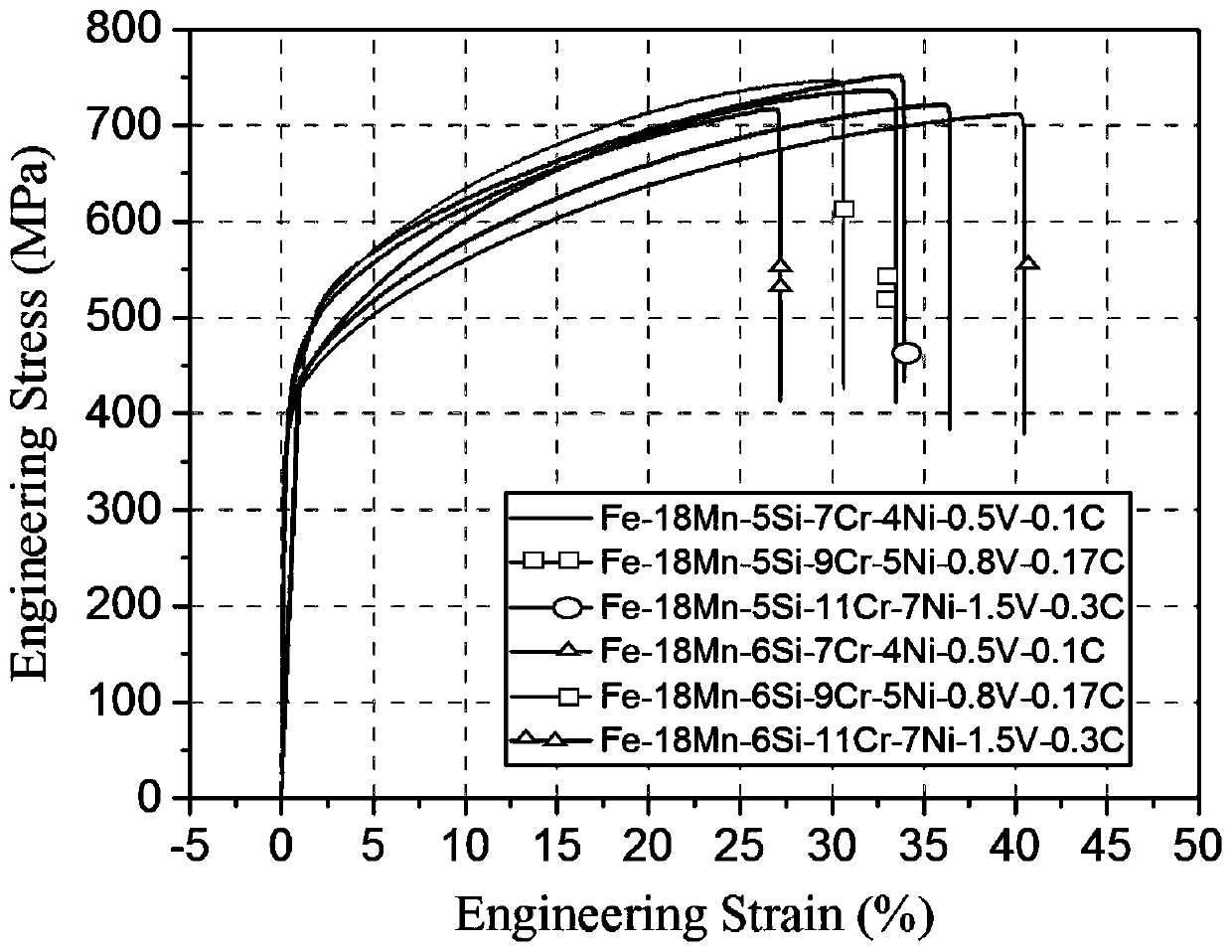

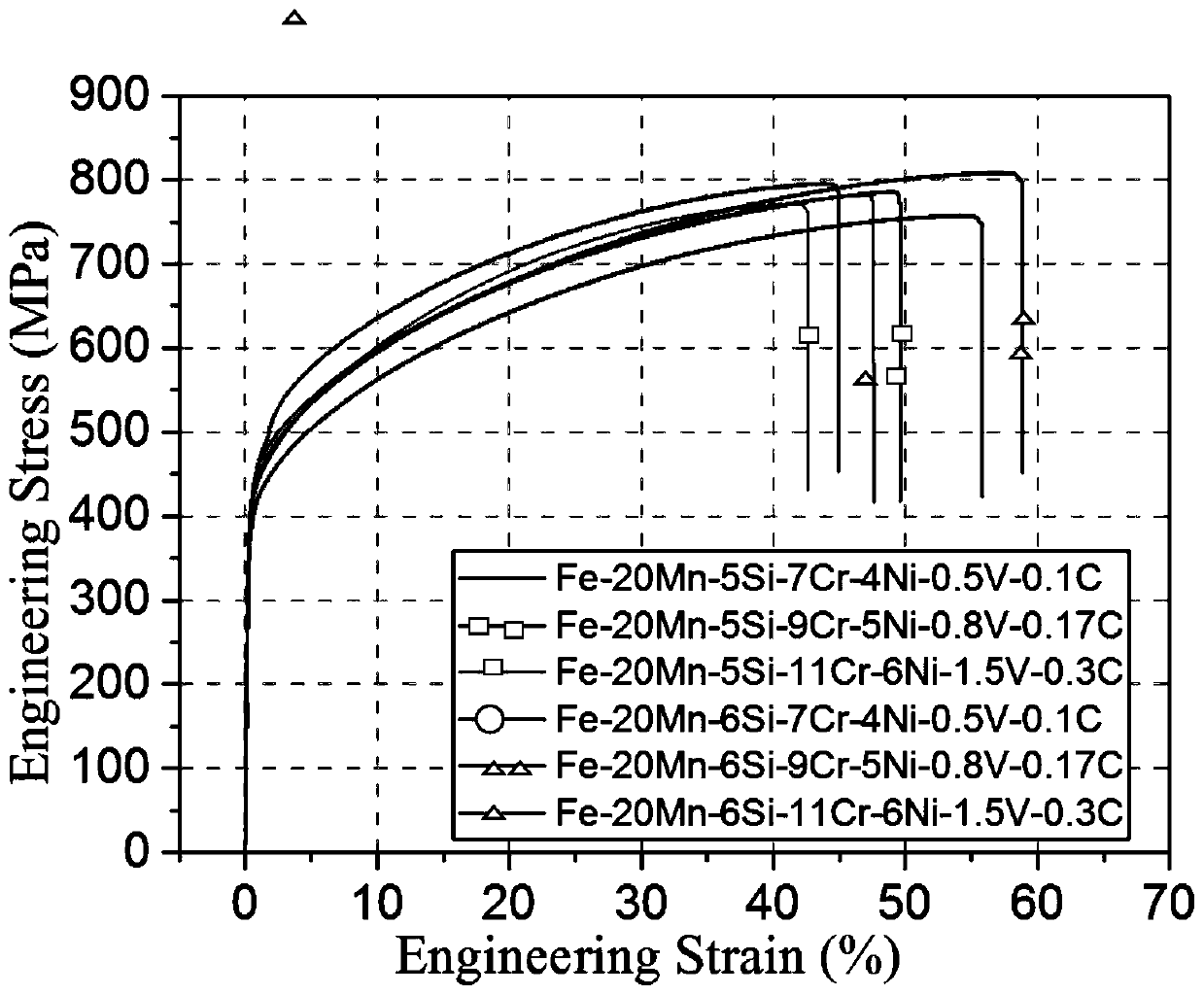

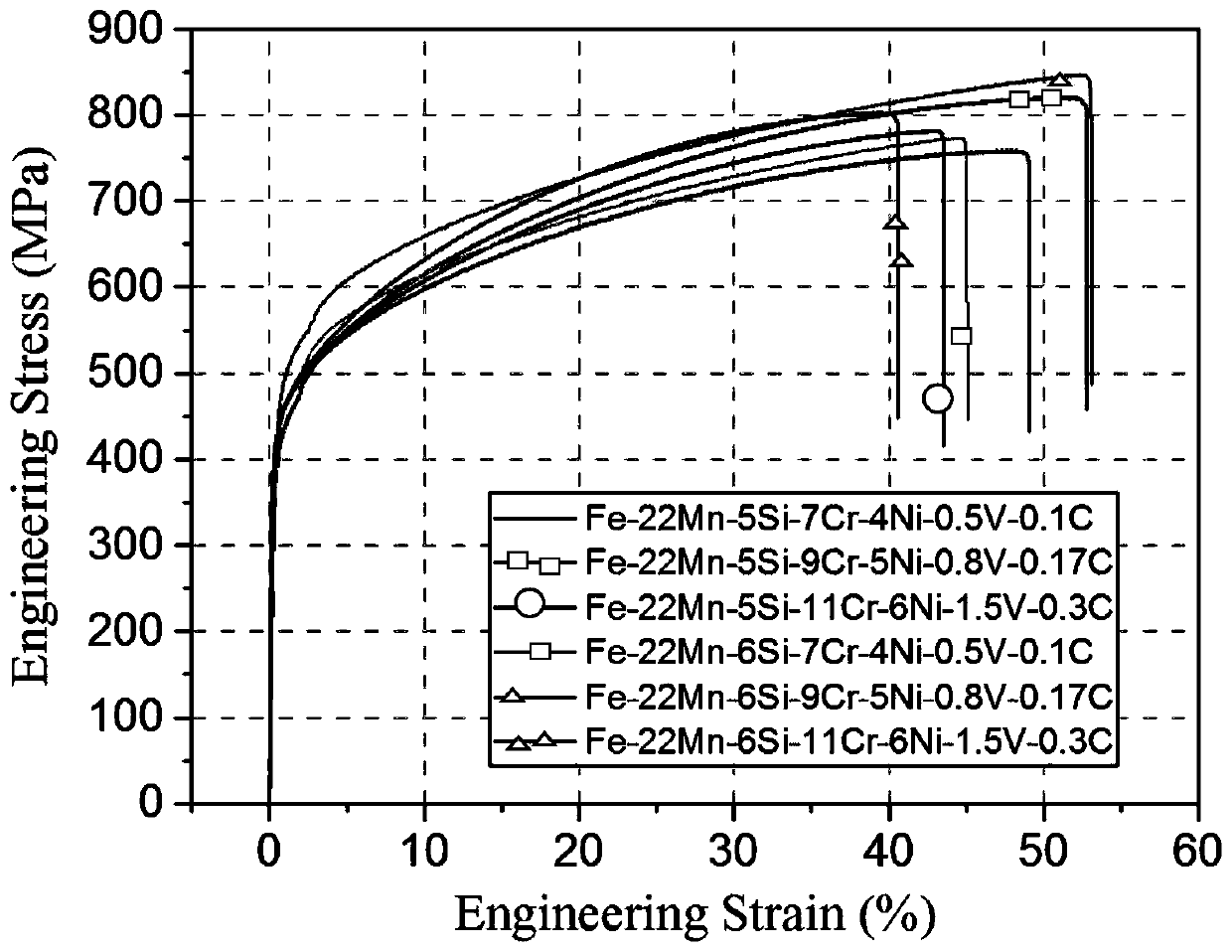

Embodiment 1

[0035] The components and mass percentages of the high-strength and high-plastic shape memory steel with recovery stress>500 MPa and recovery strain>4% in this embodiment are: Mn: 18%, Si: 5%, Cr: 7%, Ni: 4%, V: 0.5%, C: 0.1%, and the balance is Fe.

[0036] Wherein, the mass ratio of Cr and Ni is 1.75, and the atomic number ratio of V and C is 1.18.

[0037] The preparation process and steps are as follows:

[0038] After batching the raw materials according to the above percentages, they are melted in a vacuum medium frequency induction melting furnace, using argon as a protective atmosphere, with a vacuum of 0.1Pa, and filling with argon to 0.7×10 5 Pa, the heating temperature is 1500°C to 1550°C, the frequency of the induced current is 2500Hz, and the voltage is 380V, and the alloy ingot is turned and smelted for 3 to 5 times. The smelted ingot was subjected to wire cutting, cut into plates with a thickness of 22 mm, and then homogenized at 1000° C. for 5 hours. After wat...

Embodiment 2

[0052] The difference between this example and Example 1 is that in this example, the composition and mass percentage of high-strength and high-plastic shape memory steel with recovery stress>500MPa and recovery strain>4% are: Mn: 18%, Si: 5% , Cr: 9%, Ni: 5%, V: 0.8%, C: 0.17%, and the balance is Fe.

[0053] Wherein, the mass ratio of Cr and Ni is 1.8, and the atomic number ratio of V and C is 1.11.

[0054] The preparation process and steps are as follows:

[0055] After batching the raw materials according to the above percentages, they are melted in a vacuum medium frequency induction melting furnace, using argon as a protective atmosphere, with a vacuum of 0.1Pa, and filling with argon to 0.7×10 5 Pa, the heating temperature is 1500°C to 1550°C, the frequency of the induced current is 2500Hz, and the voltage is 380V, and the alloy ingot is turned and smelted for 3 to 5 times. Wire-cut the ingot obtained from smelting, cut into plates with a thickness of 22mm, and then ...

Embodiment 3

[0058] The difference between this embodiment and Embodiments 1 and 2 is that in this embodiment, the composition and mass percentage of high-strength and high-plasticity shape memory steel with recovery stress > 500 MPa and recovery strain > 4% are: Mn: 18%, Si: 5 %, Cr: 11%, Ni: 6%, V: 1.5%, C: 0.3%, and the balance is Fe.

[0059] Among them, the mass ratio of Cr and Ni is 1.83, and the atomic number ratio of V and C is 1.18.

[0060] The preparation process and steps are as follows:

[0061] After batching the raw materials according to the above percentages, they are melted in a vacuum medium frequency induction melting furnace, using argon as a protective atmosphere, with a vacuum of 0.1Pa, and filling with argon to 0.7×10 5 Pa, the heating temperature is 1500°C to 1550°C, the frequency of the induced current is 2500Hz, and the voltage is 380V, and the alloy ingot is turned and smelted for 3 to 5 times. Wire-cut the ingot obtained from smelting, cut into plates with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com