Ultra-low temperature service nickel-titanium-niobium shape memory alloy

A memory alloy, nickel-titanium-niobium technology, applied in the field of shape memory alloys, can solve the problem that the alloy cannot fully meet the requirements of ultra-low temperature service of connectors and fasteners, and achieve the effect of high recovery stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

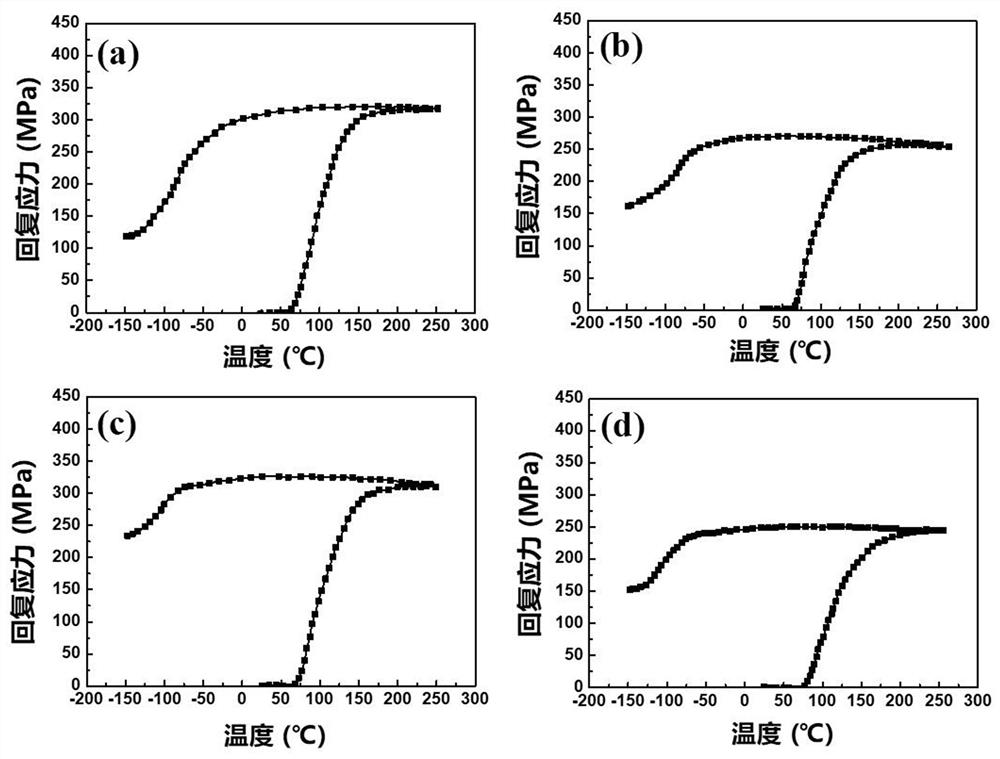

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It is worth noting that the given embodiments can not be interpreted as limiting the protection scope of the present invention, and some non-essential improvements and adjustments made by those skilled in the art according to the content of the present invention above should still belong to the protection of the present invention. scope.

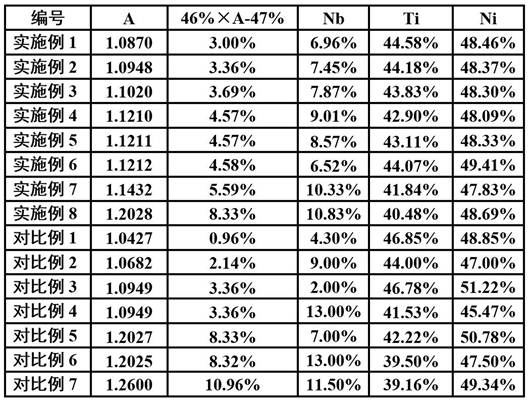

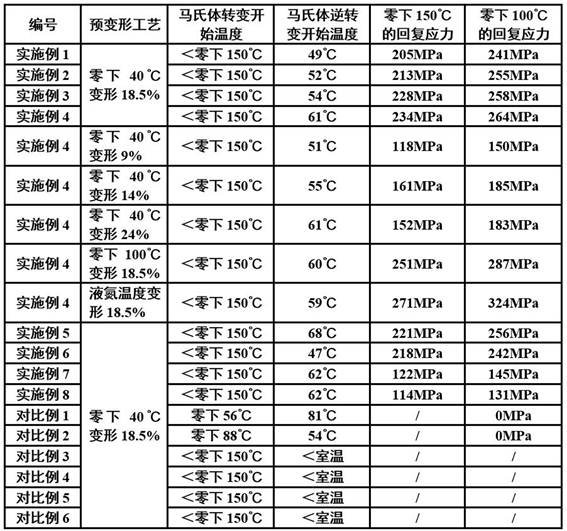

[0011] The alloy compositions of Examples 1-8 and Comparative Examples 1-7 are shown in Table 1, wherein A represents the atomic percentage content ratio of nickel and titanium, and Nb, Ti and Ni represent the atomic percentage content of their respective elements. Examples 1-8 all satisfy the two conditions of 1.087≤A≤1.25 and (46%×A-47%)≤Nb≤12%, and Example 5 also meets the condition of Nb=46%×A-43%. Comparative examples 1, 2 and 7 do not satisfy the condition of 1.087≤A≤1.25, but satisfy the condition of (46%×A-47%)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com