Preparation method of ultrahigh recovery stress Ti-Ni-Cu shape memory alloy thin film

A ti-ni-cu and memory alloy technology, which is applied in the field of preparation of ultra-high recovery stress Ti-Ni-Cu shape memory alloy thin films, can solve the problems such as the inability to meet the ultra-high unit volume output power of micro-drive components, and meet the Effects of small size, reduced phase transition temperature hysteresis, and ultra-high recovery stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

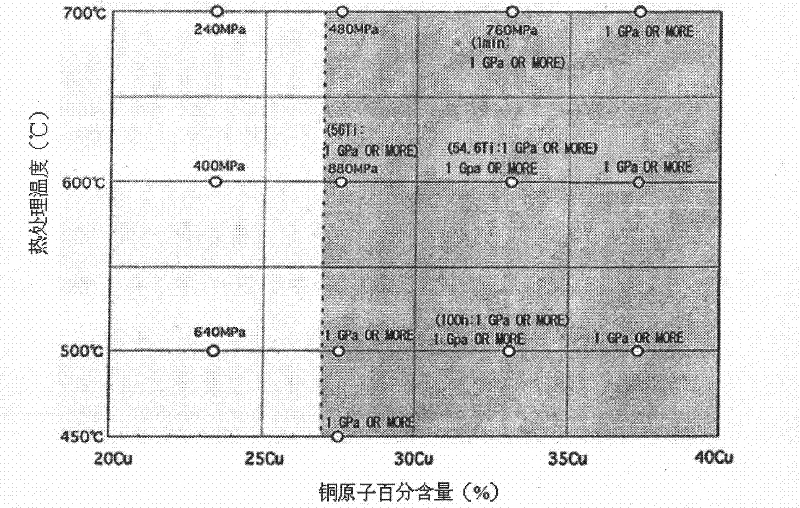

[0011] Embodiment 1: The ultra-high recovery stress Ti-Ni-Cu shape memory alloy thin film of this embodiment is composed of 50.5%-66.6% Ti, 15%-40% Cu and the balance Ni.

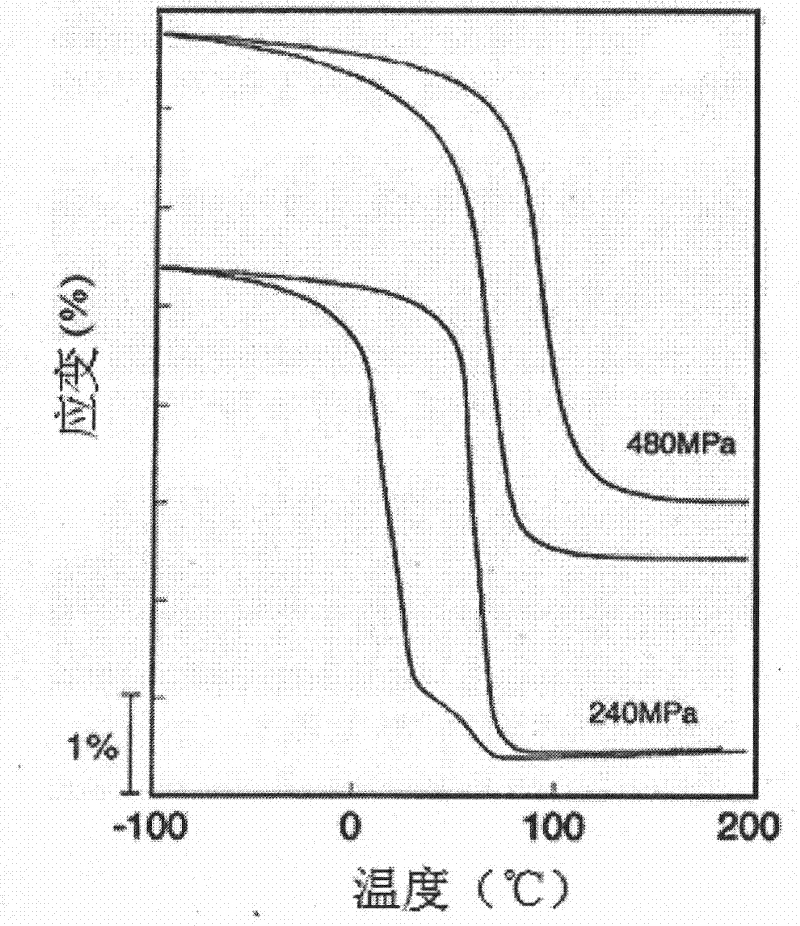

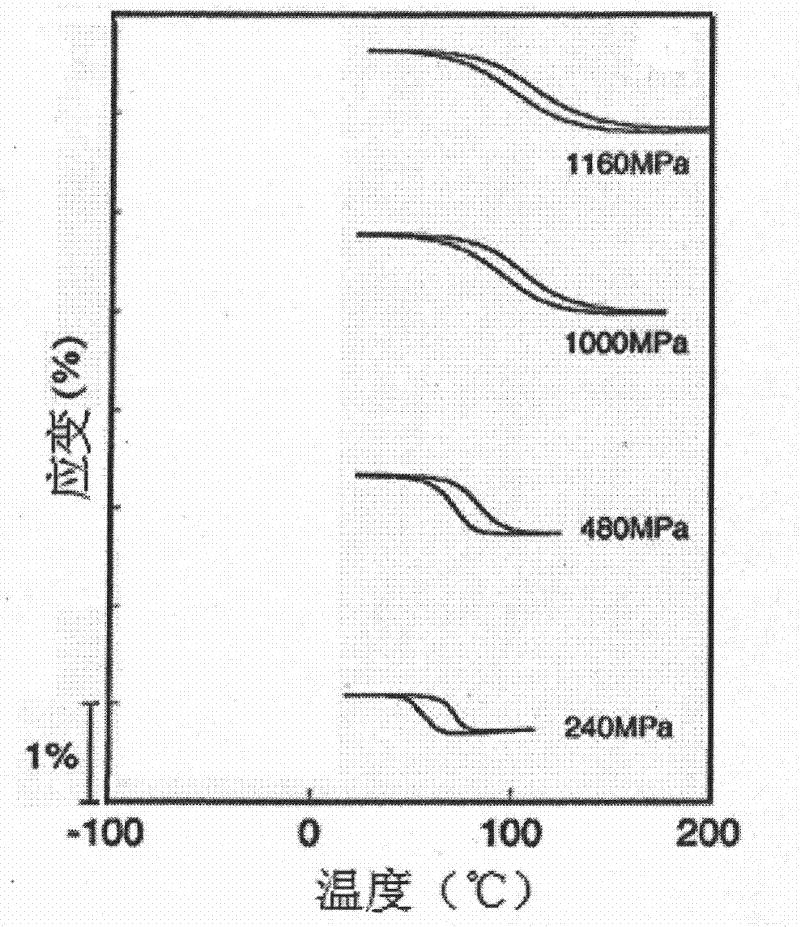

[0012] The Ti-Ni-Cu shape memory alloy thin film of the present invention reduces the phase transition temperature hysteresis, the grain size is 50-500nm, the thickness is 3-101μm, has ultra-high recovery stress (higher than 1GPa) and fast response speed The advantages of the micro-drive element can meet the requirements of small size and ultra-high driving force.

specific Embodiment approach 2

[0013] Specific embodiment two: the preparation method of Ti-Ni-Cu shape memory alloy thin film in this embodiment is characterized in that the preparation method of Ti-Ni-Cu shape memory alloy thin film is carried out according to the following steps: with glass as substrate , put the glass into the vacuum chamber of the magnetron sputtering apparatus after cleaning, and evacuate until the vacuum degree in the vacuum chamber is 3×10 -5 Pa; then argon gas is introduced to make the partial pressure of argon gas reach 0.01-0.3Pa, nickel, titanium and copper are used as cathodes to deposit by magnetron co-sputtering method for 1-3h, and during the deposition process, the sputtering of target cathode nickel The power is 150-300W, the sputtering power of target cathode titanium is 1000W, the sputtering power of target cathode copper is 20-50W, and the substrate temperature is 200℃; ~700℃, vacuum degree is 2.7×10 -5 Vacuum heat treatment is carried out under Pa condition for 1min t...

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment differs from Embodiment 2 in that: the magnetron sputtering apparatus is an ultra-high vacuum multi-target magnetron sputtering apparatus. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com