Patents

Literature

73 results about "Stacking-fault energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

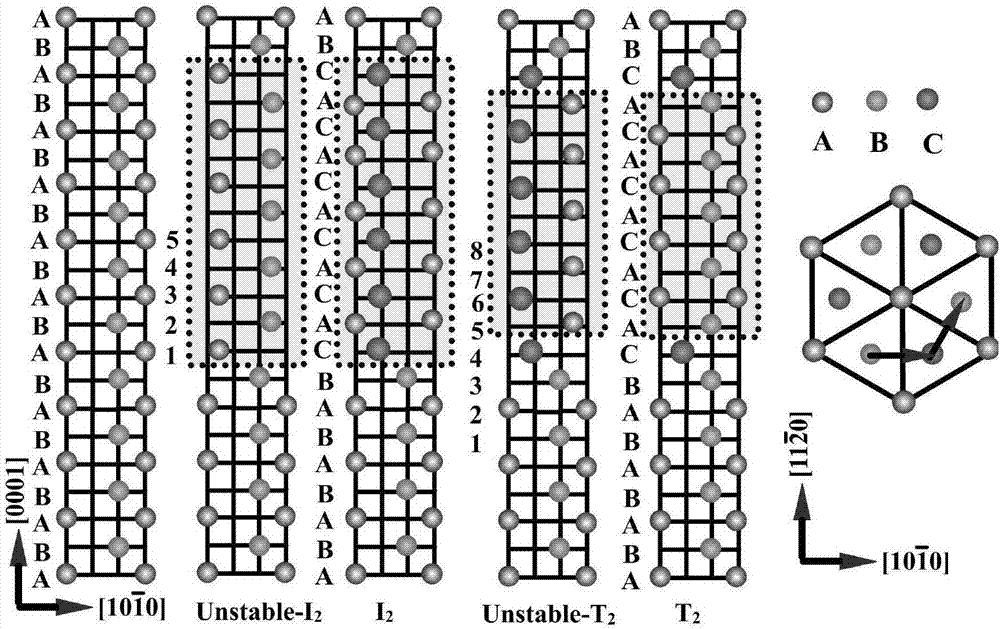

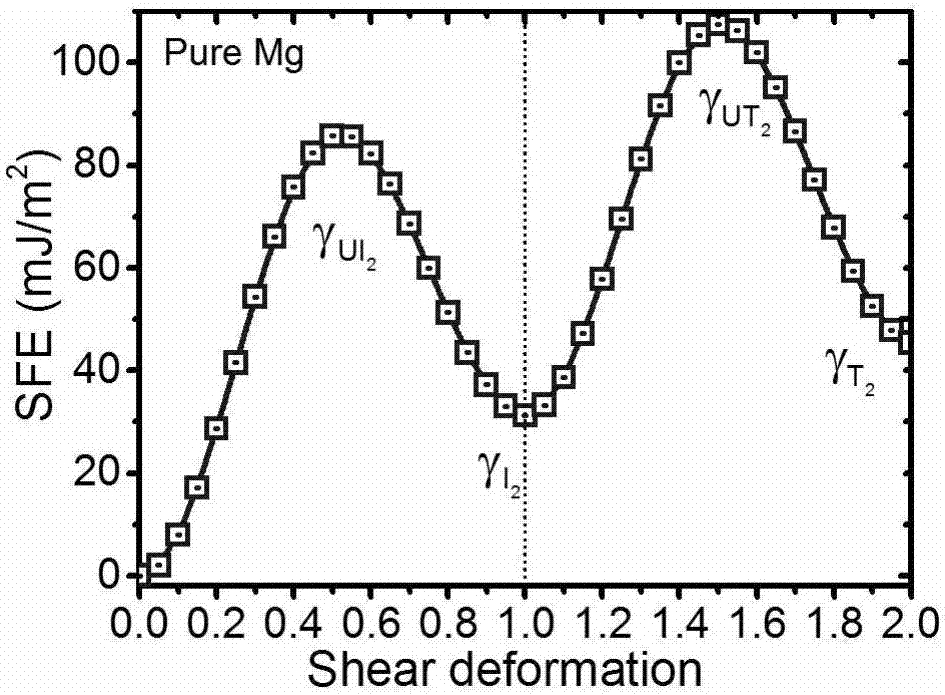

The stacking-fault energy (SFE) is a materials property on a very small scale. It is noted as γSFE in units of energy per area. A stacking fault is an interruption of the normal stacking sequence of atomic planes in a close-packed crystal structure. These interruptions carry a certain stacking-fault energy. The width of stacking fault is a consequence of the balance between the repulsive force between two partial dislocations on one hand and the attractive force due to the surface tension of the stacking fault on the other hand. The equilibrium width is thus partially determined by the stacking-fault energy. When the SFE is high the dissociation of a full dislocation into two partials is energetically unfavorable, and the material can deform either by dislocation glide or cross-slip. Lower SFE materials display wider stacking faults and have more difficulties for cross-slip. The SFE modifies the ability of a dislocation in a crystal to glide onto an intersecting slip plane. When the SFE is low, the mobility of dislocations in a material decreases.

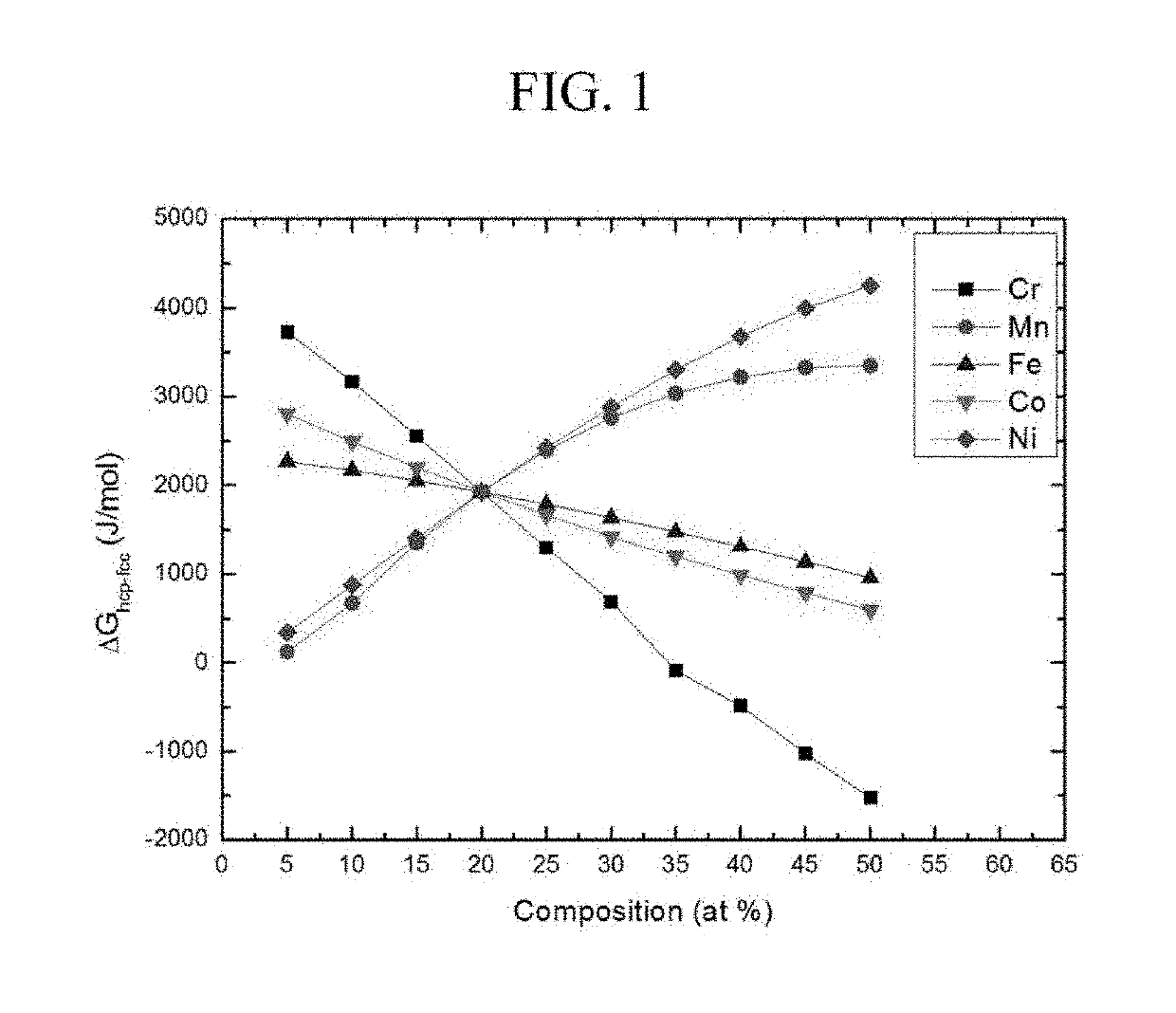

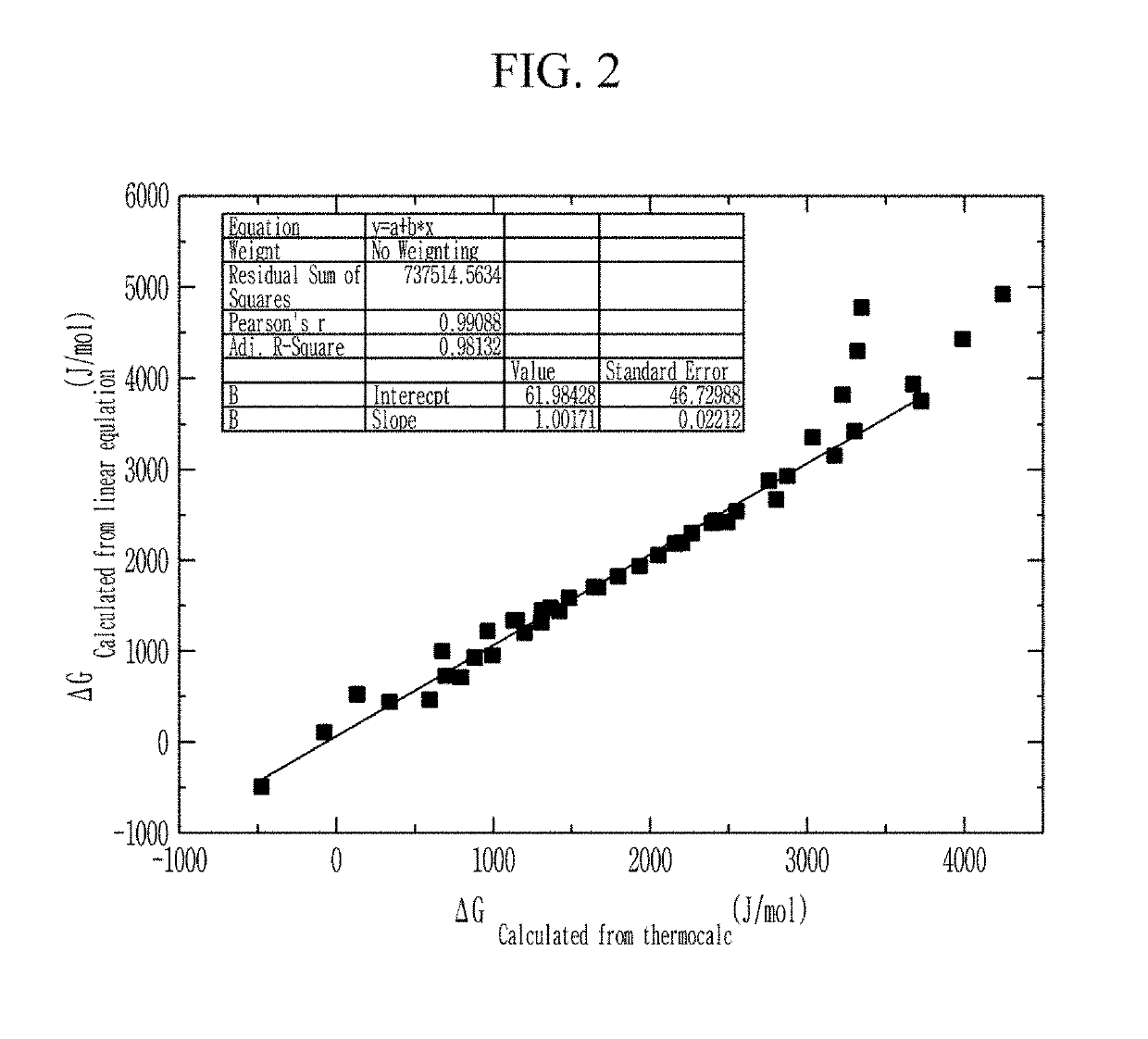

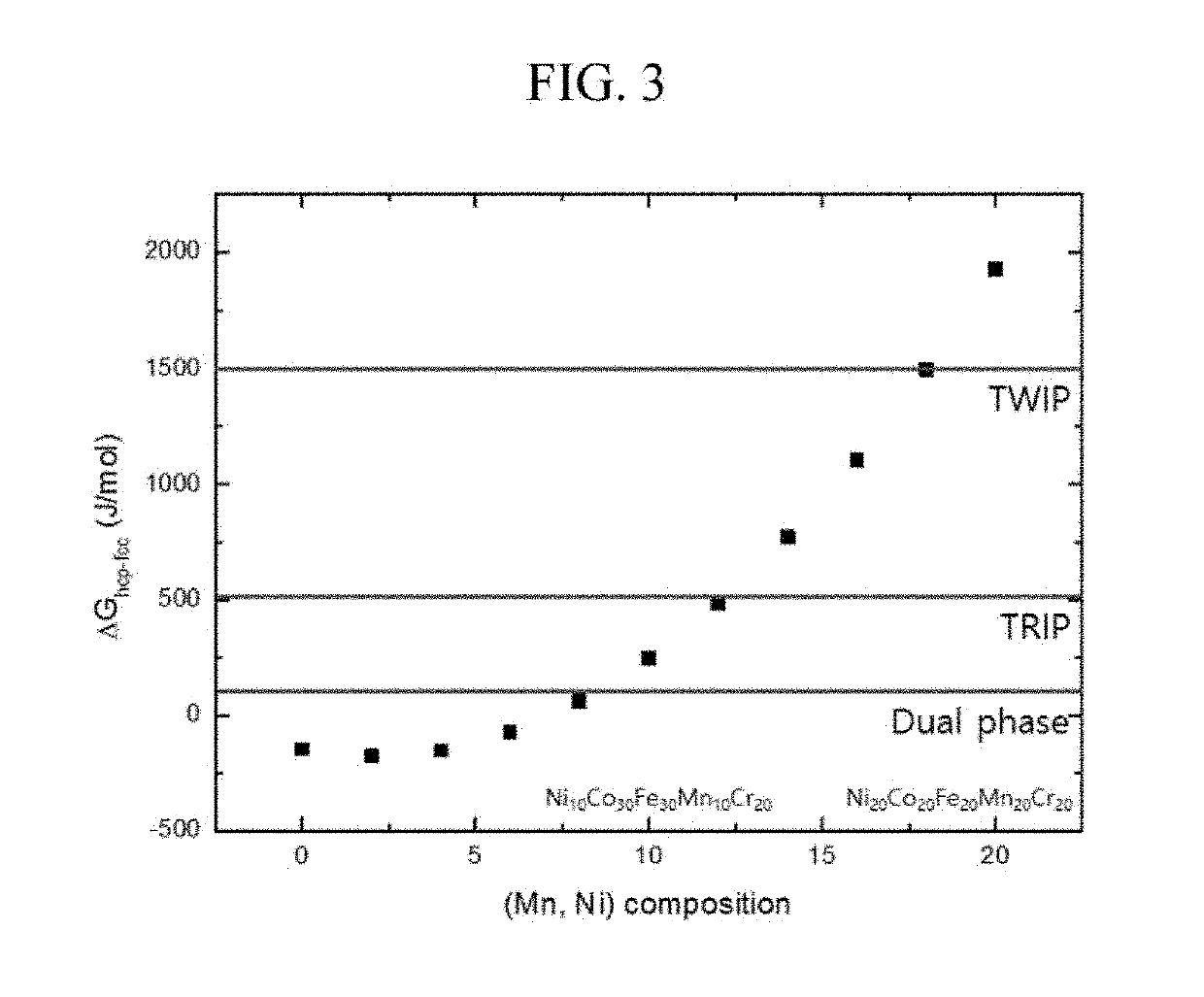

High entropy alloy having twip/trip property and manufacturing method for the same

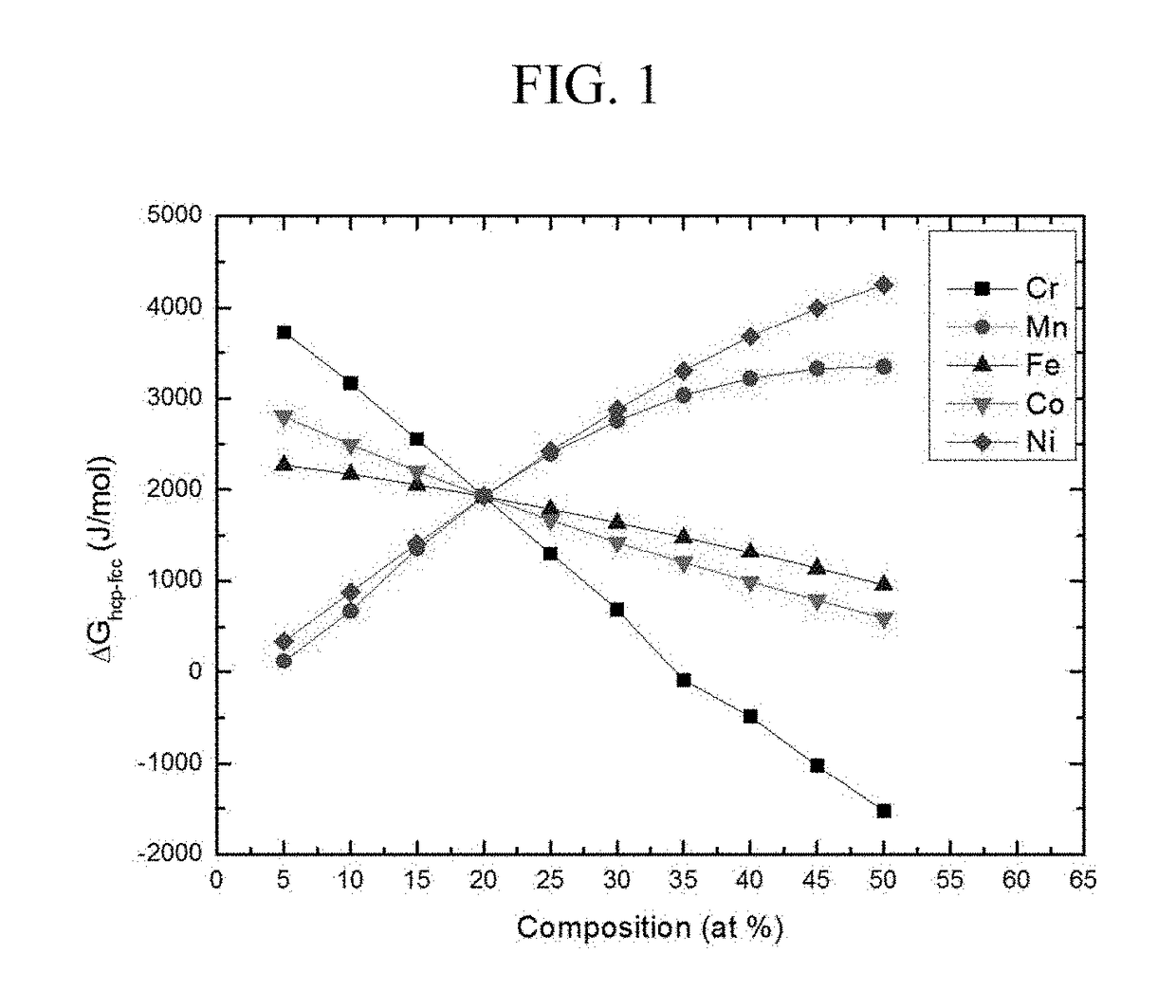

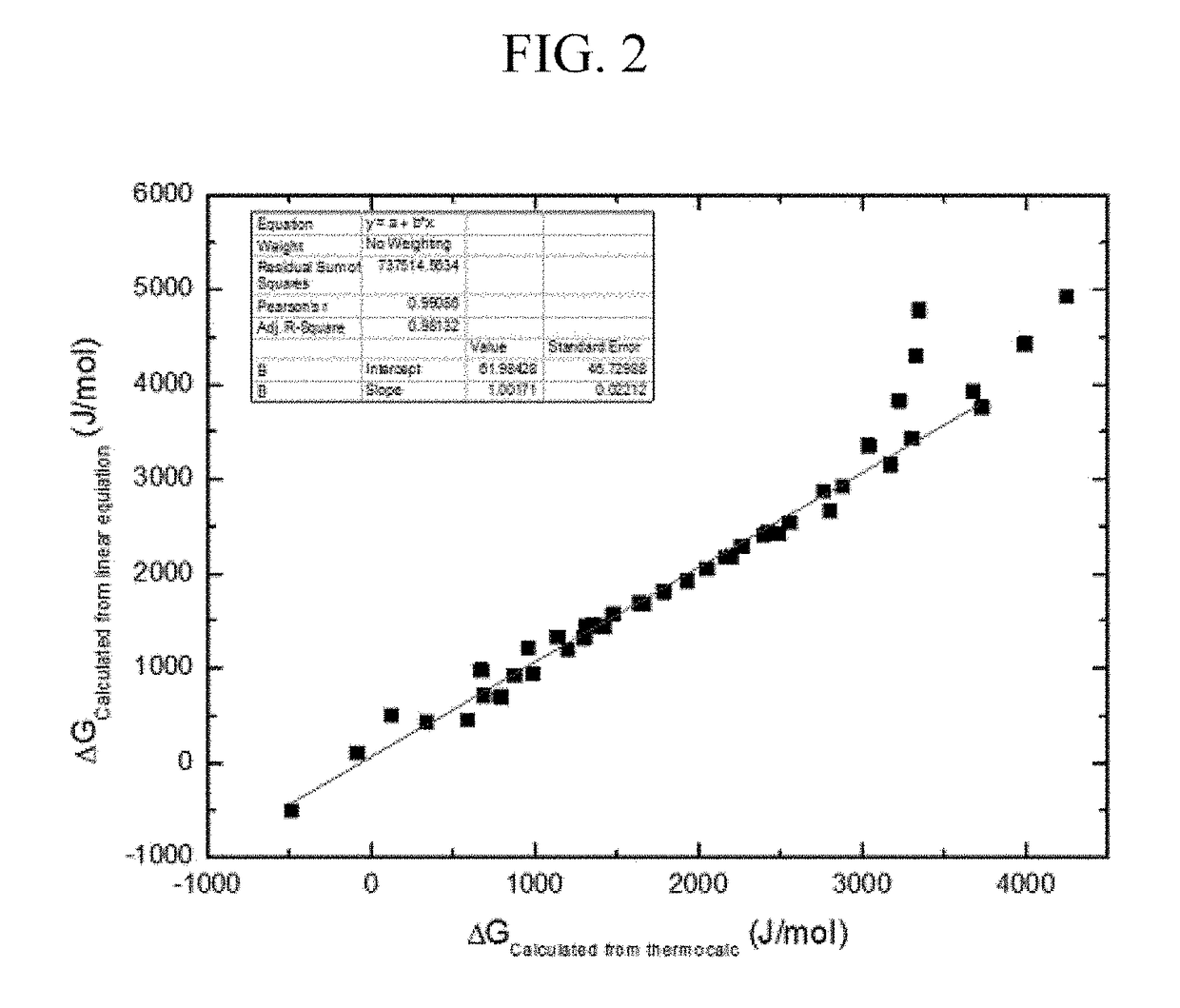

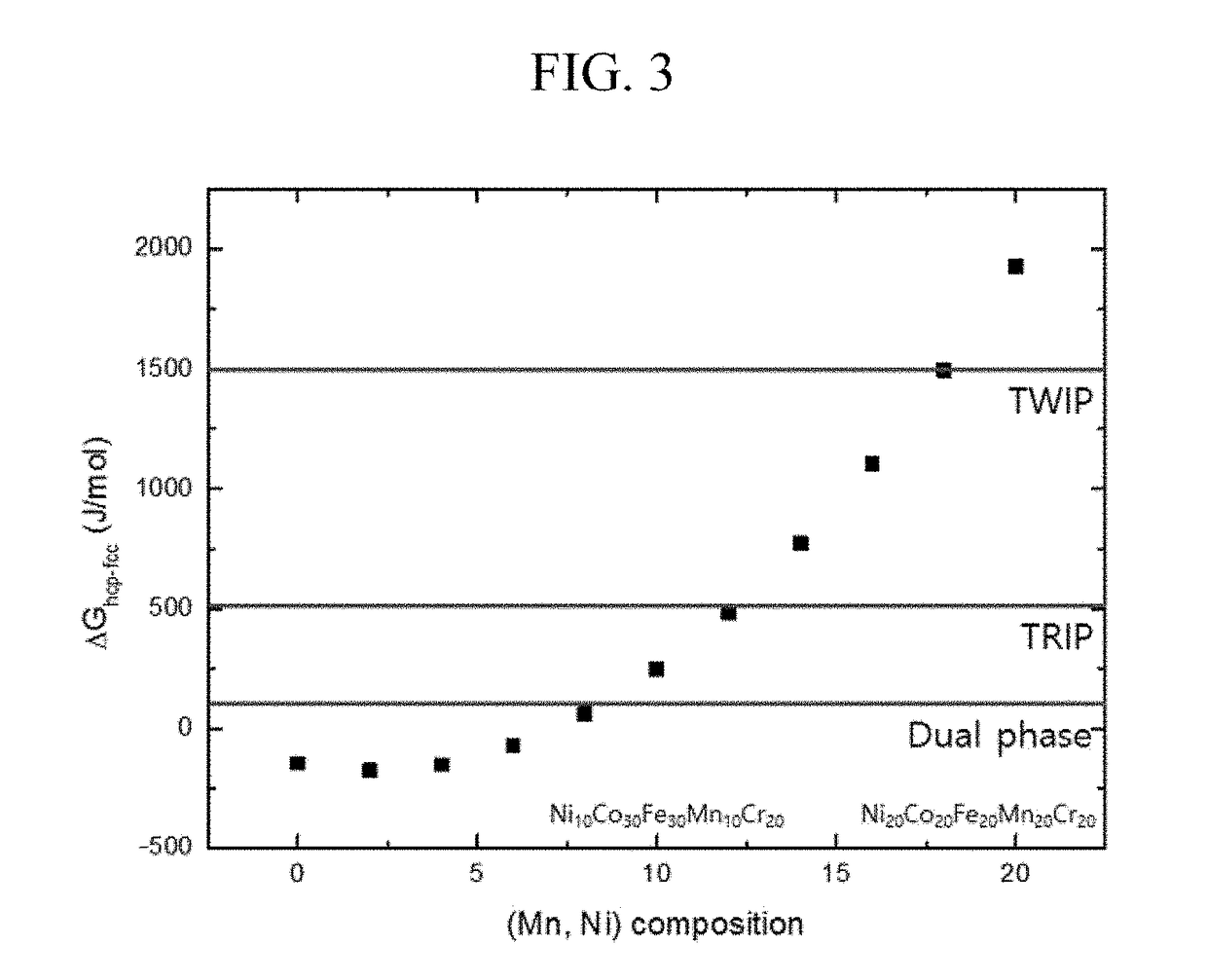

The present invention relates to a high entropy alloy having more improved mechanical properties by controlling contents of additive elements in a NiCoFeMnCr 5-element alloy to control stacking fault energy, thereby controlling stability of a γ austenite phase to control a transformation mechanism, wherein the stacking fault energy is controlled in a composition range of NiaCobFecMndCre (a+b+c+d+e=100, 1≦a≦50, 1≦b≦50, 1≦c≦50, 1≦d≦50, 10≦e≦25, and 77a−42b−22c+73d−100e+2186≦1500), and thus, the γ austenite phase exhibits a twin-induced plasticity (TWIP) property or a transformation induced-plasticity (TRIP) property in which the γ austenite phase is subjected to phase transformation into an ε martensite phase or an α′ martensite phase, under stress, thereby having improved strength and elongation at the same time to have excellent mechanical properties.

Owner:SEOUL NAT UNIV R&DB FOUND

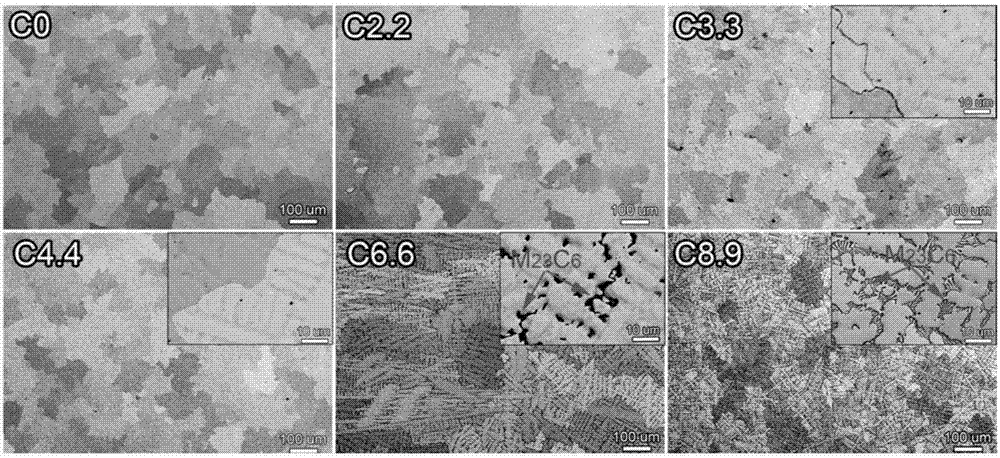

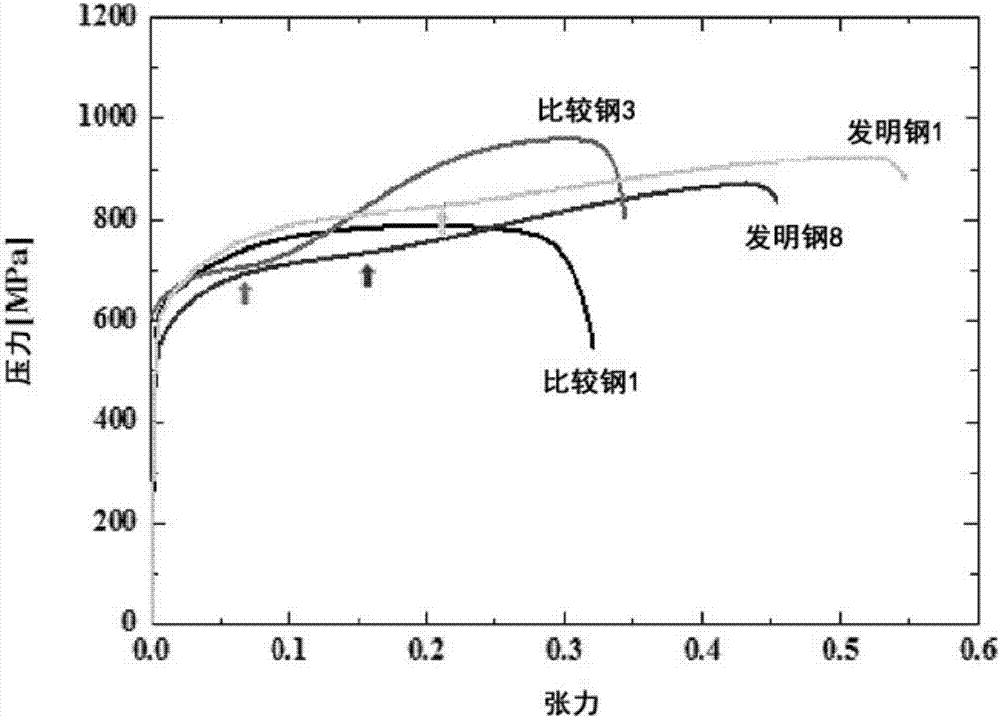

High-performance high-entropy alloy and processing method thereof

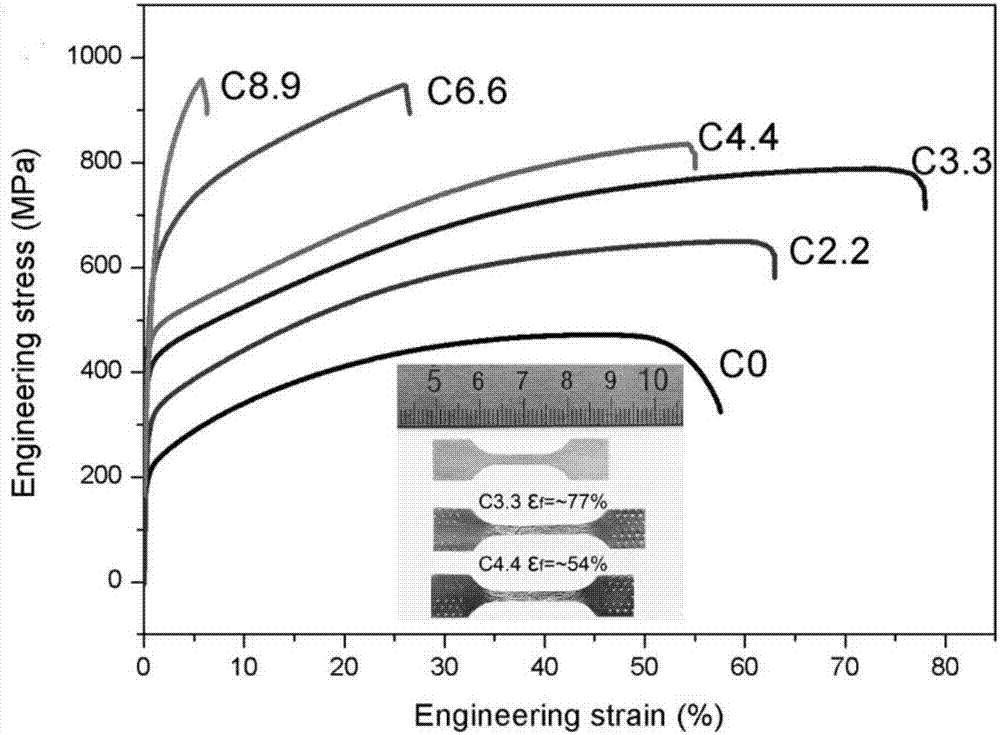

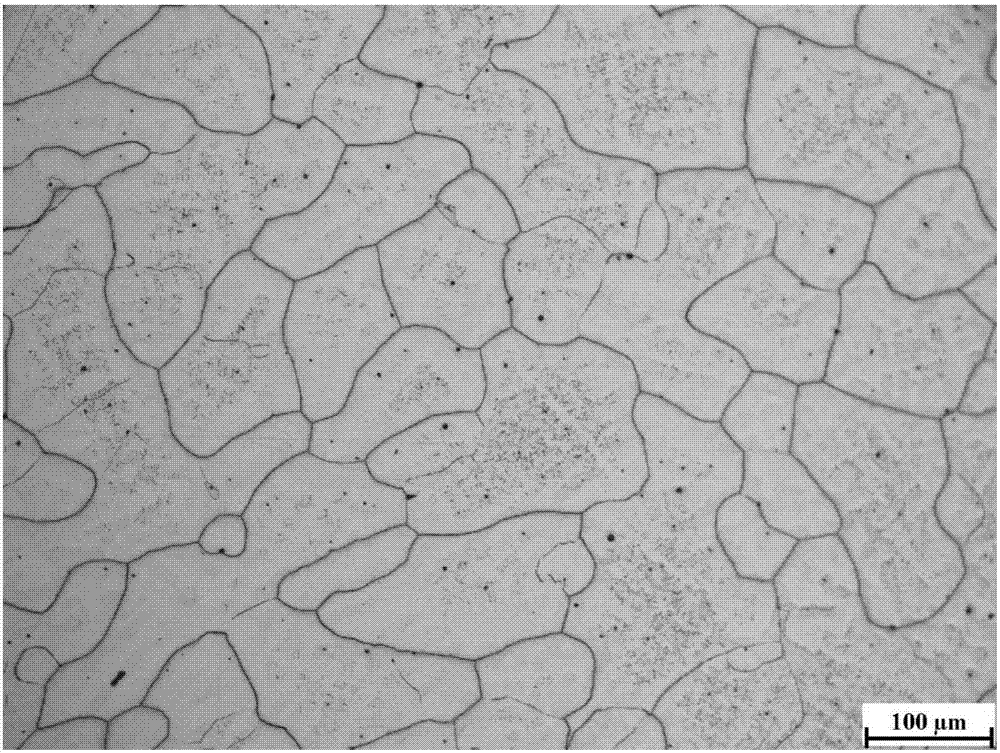

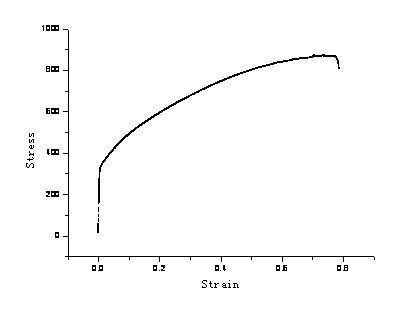

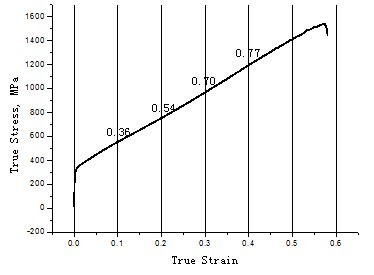

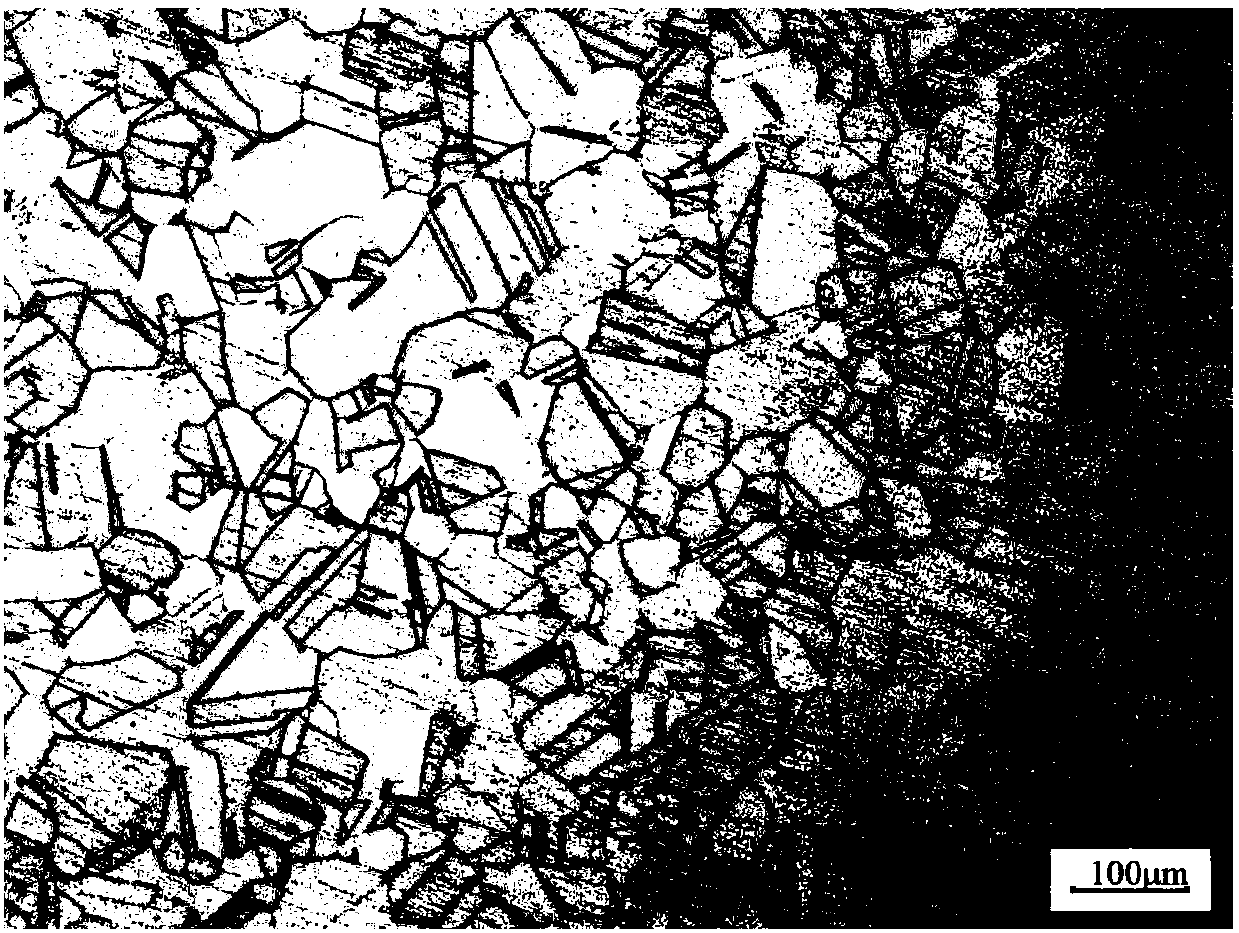

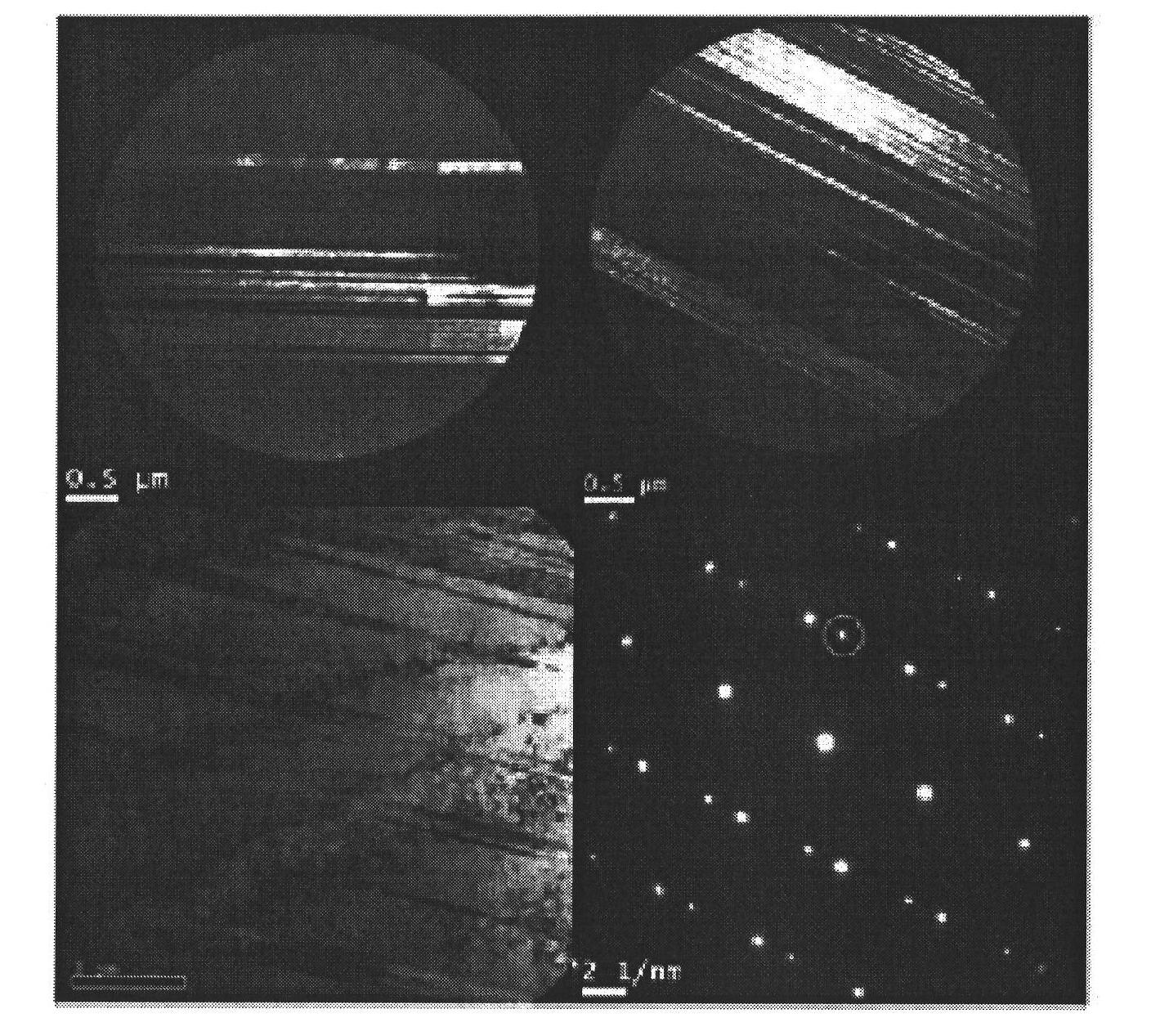

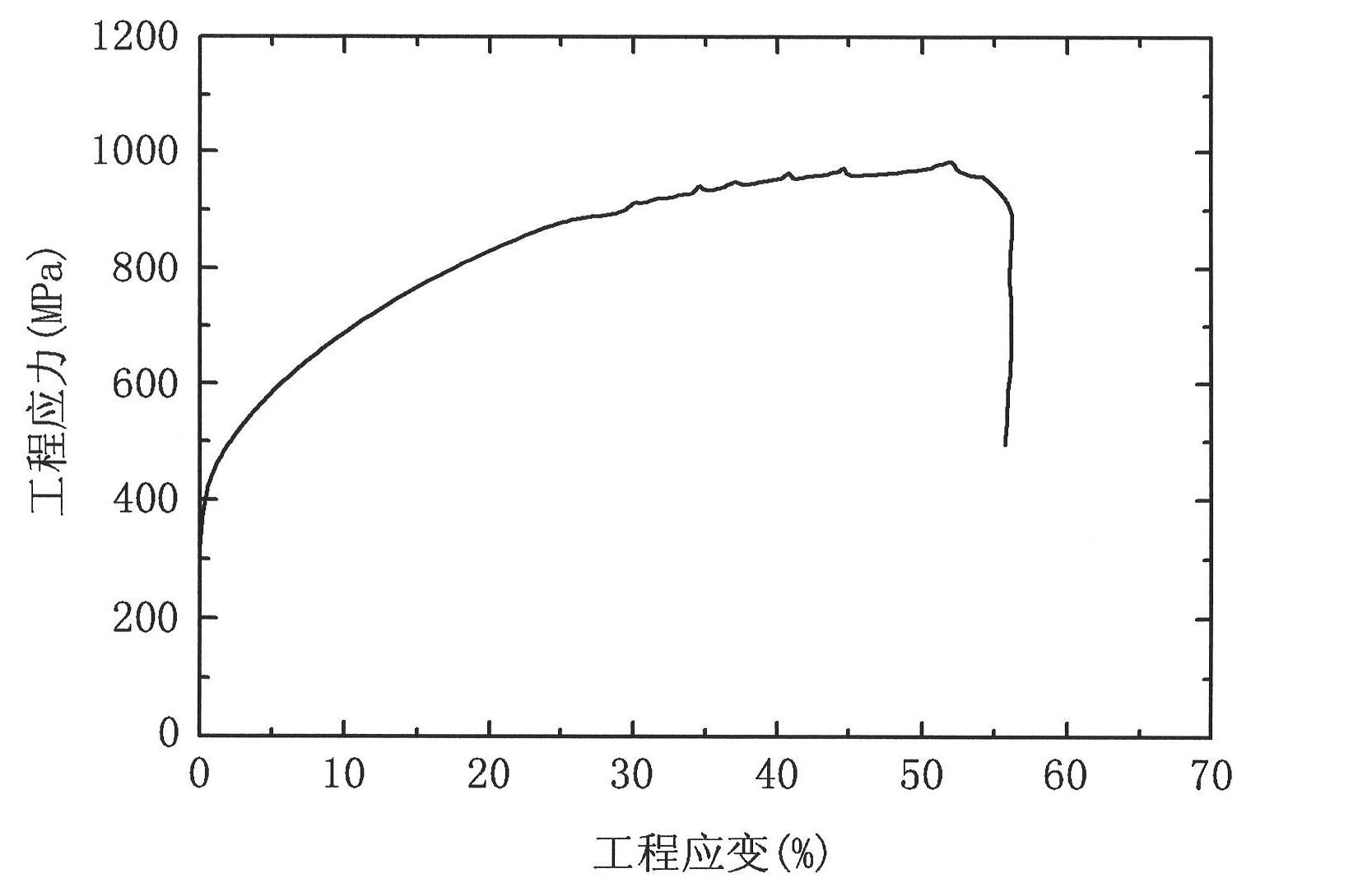

The invention discloses a high-performance high-entropy alloy and a processing method thereof. Certain content of an element carbon is added into a Fe40Mn40Co10Cr10 alloy to form an interstitial solid solution with a basal body, so that stacking fault energy of the material can be effectively reduced, twin crystals can be induced under the room-temperature condition, and extra strength increment is provided for the basal body by performing solid solution and separating carbides through the element carbon. The element carbon is used as a good interstitial atom and the carbide is used as an effective precipitation strength phase; heat preservation is performed for a relatively long time at a relatively high temperature in the last step, an as-forged microstructure is partly or completely eliminated, and part of the precipitated phase is dissolved to form a nearly single phase structure, so that the alloy has relatively great performance controllable space again on the basis of higher performance level, further strengthening is favorably performed through other strengthening ways such as deformation strengthening and precipitation strengthening to obtain more reasonable strength and plasticity match; and moreover, content of overall alloy elements is reasonable, cost is low, and economical efficiency is relatively strong.

Owner:深圳市卡德姆科技有限公司

Nitrogen intensified high-carbon twin crystal inducement plastic steel material and its production technique

InactiveCN101429621AHigh elongationImprove propertiesTemperature control deviceFurnace typesHigh carbonMetallic materials

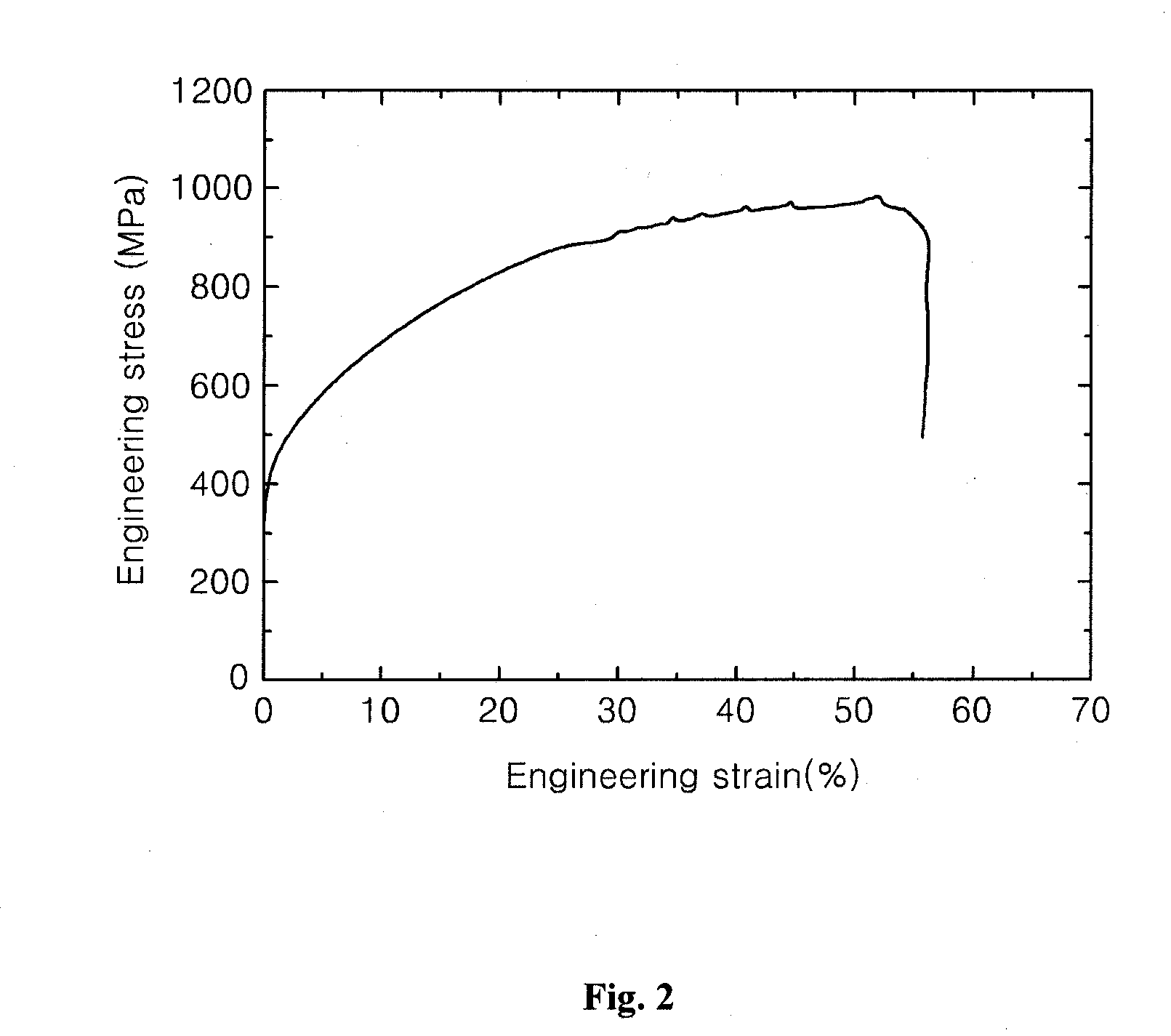

The invention relates to a technology for improving an iron and steel metallic material, in particular to a nitrogen-strengthened high-carbon twin-crystal induced plastic steel material and a method for preparing the same. The steel material is characterized by comprising the following component ranges: 0.2 to 1.0 percent of C, 15 to 35 percent of Mn, 0.04 to 0.2 weight percent of nitrogen content in control, less than 1 weight percent of Al, less than 1 weight percent of Si, less than 0.008 percent of S, less than 0.02 percent of P, and the balance being Fe. The stacking fault energy is controlled to between 20 and 60 mJ.mm<2>. The technology can obtain the proportions of strength and plasticity of different levels through process control so as to obtain the tensile strength of between 995 and 1,530MPa, the yield strength of between 470 and 1,340 MPa and the specific elongation of between 13 to and 71.5 percent. The steel material does not have a turning point of the flexible brittleness. The high-strength high-plasticity steel materials prepared by the technology can be used in the industries such as railway steel rail, saloon sedan manufacturing, engineering machinery, oil-gas delivering pipeline and liquefied natural gas container, military industry, and have important value and great application space.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method for twinning induced plasticity (TWIP) steel for low-cost large-expansibility expansion pipe and steel pipe

InactiveCN102560259AImprove corrosion resistanceImprove cleanlinessFurnace typesHeat treatment furnacesRare-earth elementMaterials science

The invention relates to a preparation method for TWIP steel for a low-cost large-expansibility expansion pipe and a steel pipe. The TWIP steel comprises the chemical components, by weight percentage, 0.30-0.65% of C, 15-30% of Mn, 0.10-1.0% of Cr, 0.01-0.20% of Al, 0.10-1.0% of Si, 0.030-0.30% of Re, S<=0.002%, P<=0.005% and the balance ferrum. Component design is instructed through alloy stacking fault energy, vacuum smelting is conducted, rare earth ferroaluminum is deoxidized, a right amount of Cr and Si elements are added, a small amount of rare earth elements are added, and steel with low content of sulphur and phosphorus and certain grain scale for the large-expansibility expansion pipe is obtained, wherein a base body of the steel is austenite, and the steel has a twinning inducedplasticity effect. The steel is manufactured into large-expansibility large-size expandable casing pipes through hot extrusion.

Owner:SOUTHWEST PETROLEUM UNIV

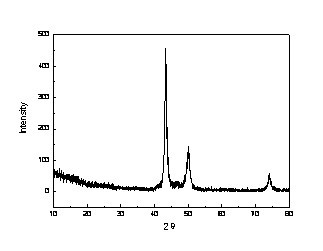

High entropy alloy having TWIP/TRIP property and manufacturing method for the same

The present invention relates to a high entropy alloy having more improved mechanical properties by controlling contents of additive elements in a NiCoFeMnCr 5-element alloy to control stacking fault energy, thereby controlling stability of a γ austenite phase to control a transformation mechanism, wherein the stacking fault energy is controlled in a composition range of NiaCobFecMndCre (a+b+c+d+e=100, 1≤a≤50, 1≤b≤50, 1≤c≤50, 1≤d≤50, 10≤e≤25, and 77a−42b−22c+73d−100e+2186≤1500), and thus, the γ austenite phase exhibits a twin-induced plasticity (TWIP) property or a transformation induced-plasticity (TRIP) property in which the γ austenite phase is subjected to phase transformation into an ε martensite phase or an α′ martensite phase, under stress, thereby having improved strength and elongation at the same time to have excellent mechanical properties.

Owner:SEOUL NAT UNIV R&DB FOUND

High-entropy alloy and preparation method thereof

InactiveCN108823481AImprove plastic deformation abilityUniform Plastic Deformation CapabilityHigh entropy alloysRoom temperature

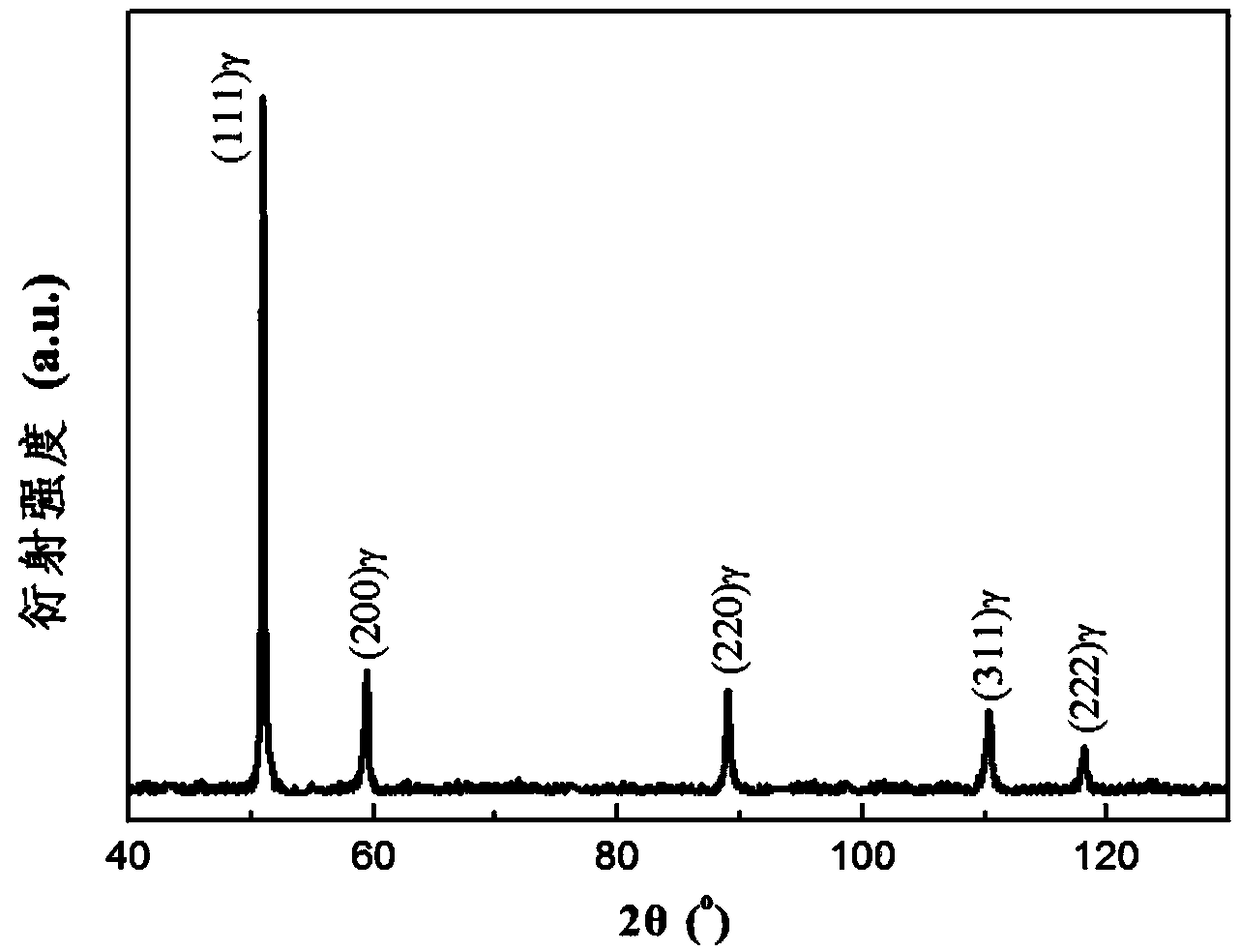

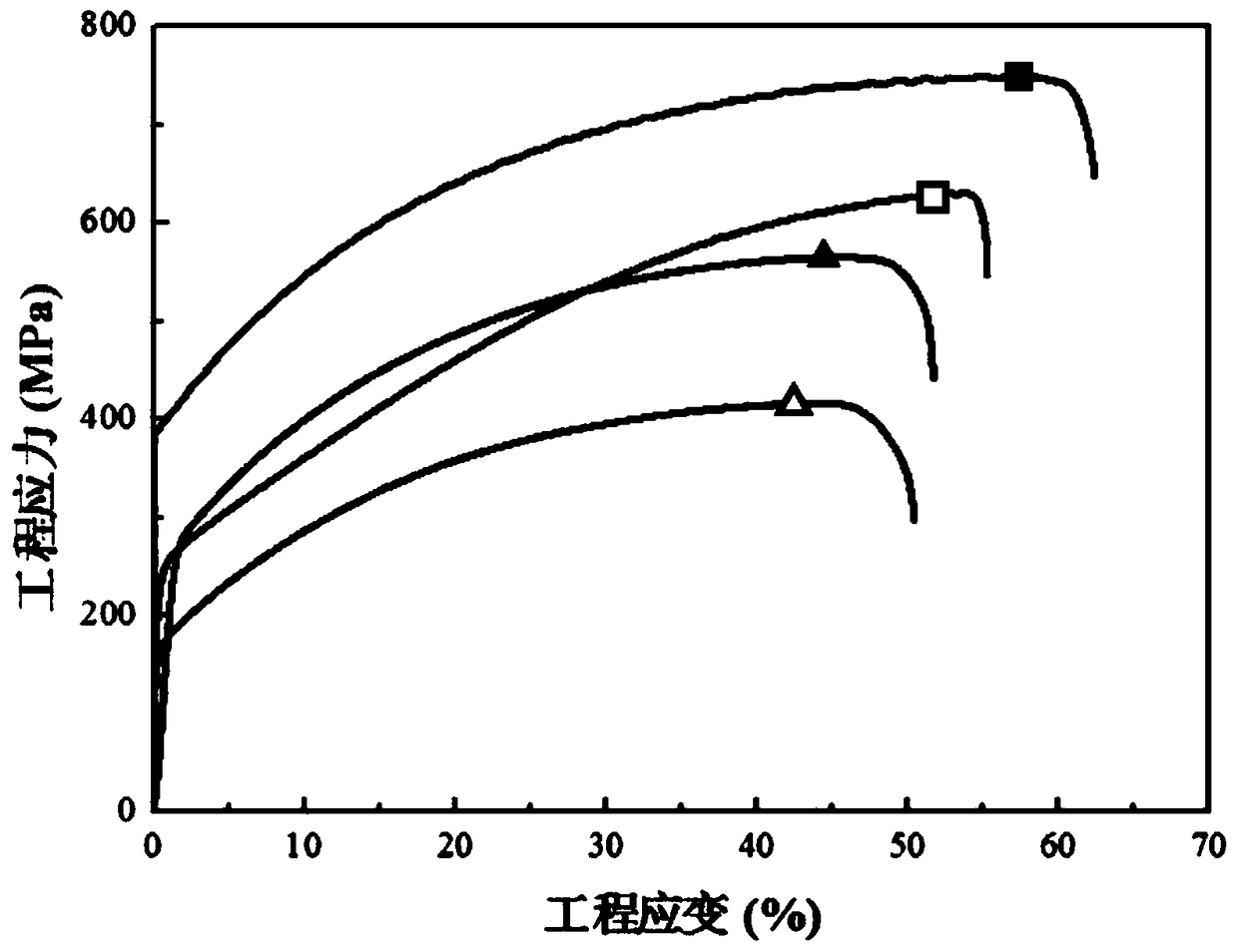

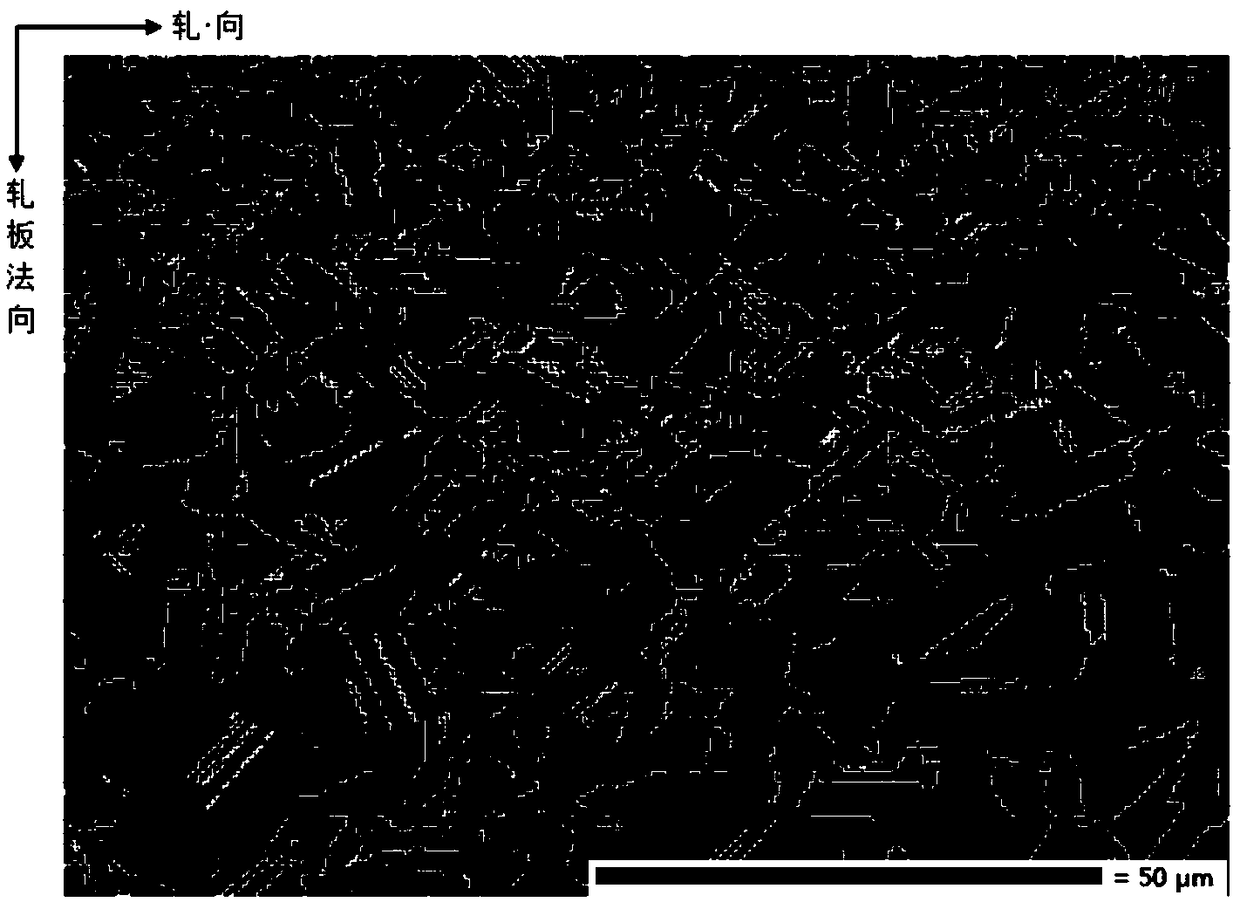

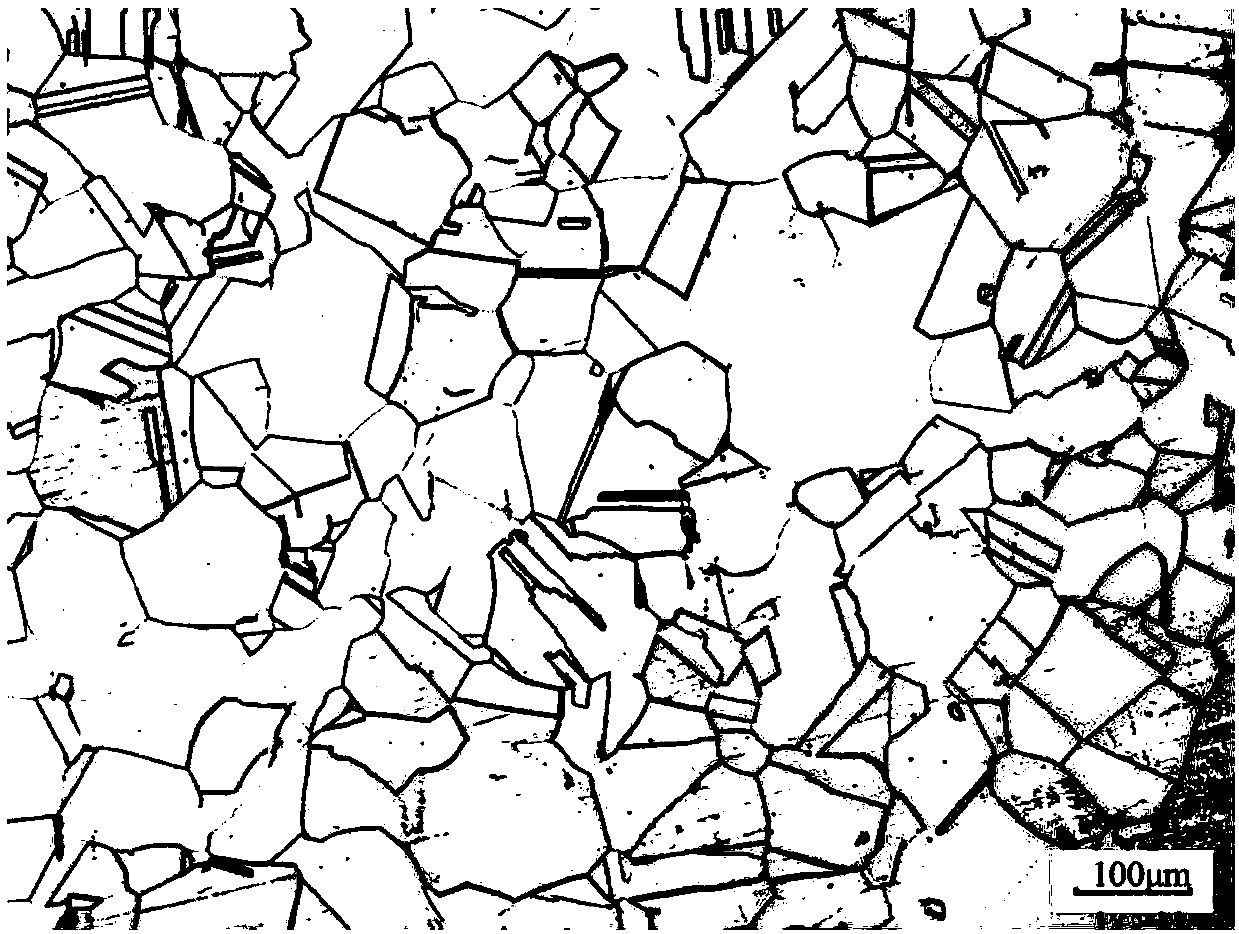

The invention provides a high-entropy alloy, which relates to the technical field of a metal material. The high-entropy alloy comprises the following elements by atom percentage content: 39.0-41.0% ofFe, 9.0-11.0% of Co, 39.0-41.0% of Mn, and 9.0-11.0% of Cr. A stacking fault energy theoretical value of the high-entropy alloy is 35 mJ / mol, and the stacking fault energy is in favor of keeping a single-phase austenite structure when the high-entropy alloy is placed under environment lower than room temperature; stress load is bear under low temperature condition, dislocation glide and mechanical twining are generated, deformation induces austenite to change to martensite, when the high-entropy alloy is 173 K, the yield strength is 670 M, the stretching rate reaches 62%, and the tensile strength can reach 750 MPa; and the plasticity and intensity are higher than the mechanical properties of a steel product used for low temperature in a traditional method.

Owner:NORTHEASTERN UNIV

High-manganese TWIP (Twining Induced Plasticity) low temperature resistant steel with high impact toughness and manufacturing method thereof

InactiveCN108118255AImprove low temperature toughnessObvious ductile-brittle transition phenomenonProcess efficiency improvementChemical compositionRoom temperature

The invention relates to a high-manganese TWIP (Twining Induced Plasticity) low temperature resistant steel with high impact toughness. The low temperature resistant steel is prepared from the chemical components in percentage by mass: 0.050 to 0.30 percent of C, 25 to 35 percent of Mn, 0.30 to 1.5 percent of Si, 2.0 to 4.0 percent of Al, and the balance of Fe and inevitable impurities; the stacking fault energy of the low temperature resistant steel at minus 196 DEG C is 25 to 40mJ / m<2>. According to the low temperature resistant steel provided by the invention, the impact energy at liquid nitrogen temperature (minus 196 DEG C) ranges from 200J to 250J, the impact energy at room temperature ranges from 300J to 350J, the yield strength ranges from 200MPa to 300MPa, the tensile strength ranges from 600MPa to 700MPa, and the percentage elongation after fracture ranges from 45 percent to 65 percent.

Owner:HEBEI UNIV OF TECH

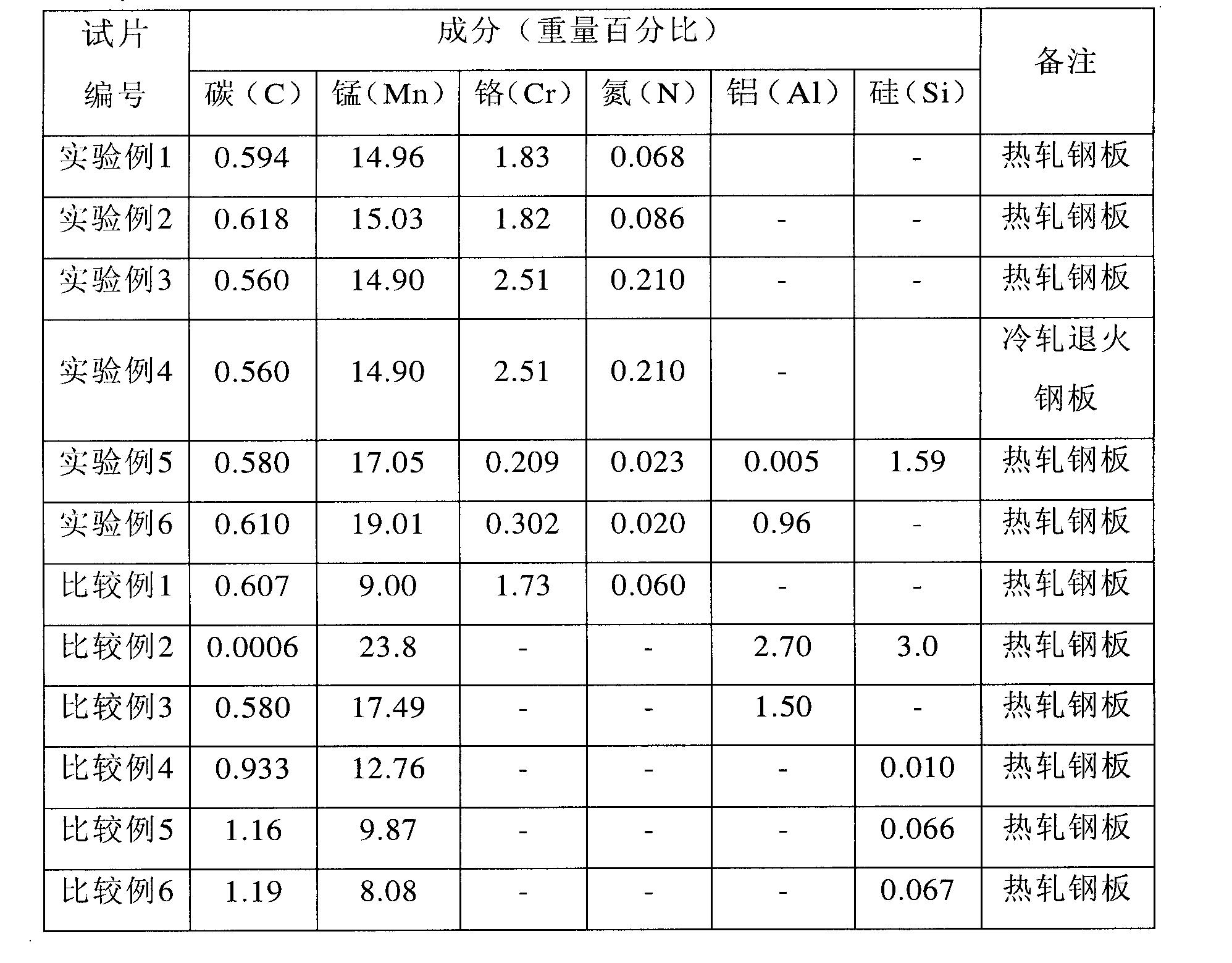

High manganese nitrogen-containing steel sheet having high strength and high ductility, and method for manufacturing same

InactiveCN102439188AEasy to processHigh tensile strengthFurnace typesHeat treatment furnacesManganeseAustenite

Owner:HYUNDAE STEEL CO LTD

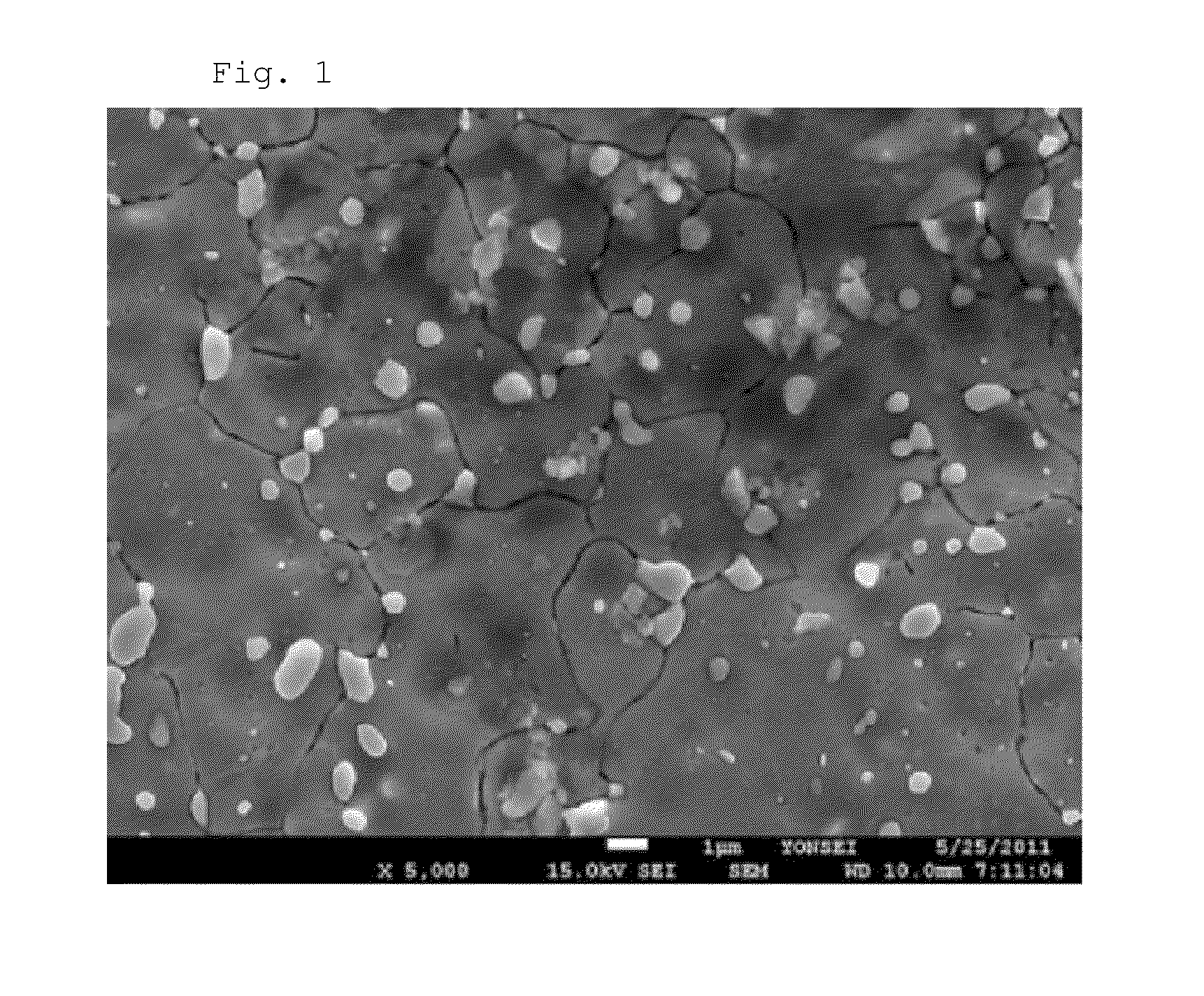

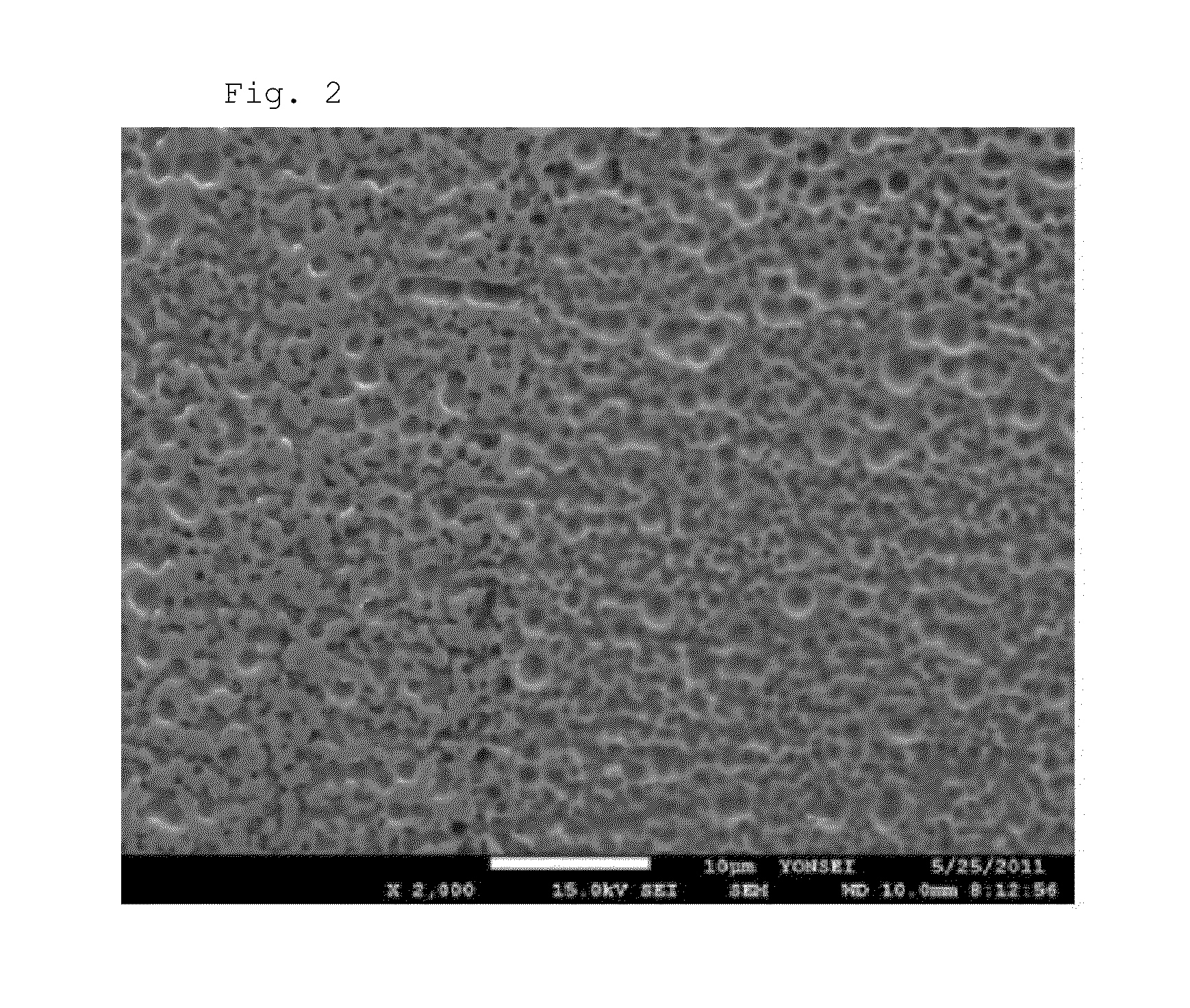

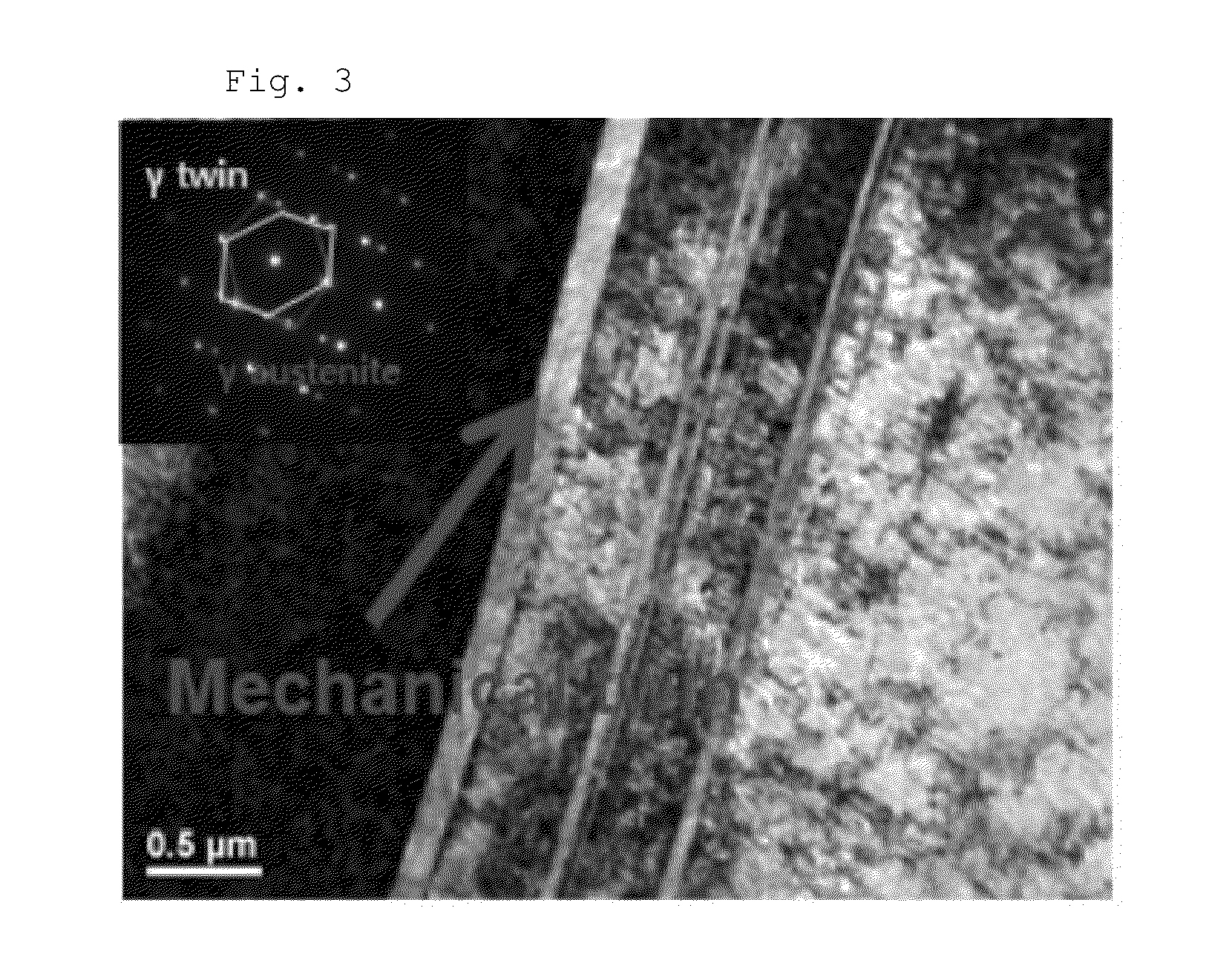

High-strength and high-ductility steel sheet and method of manufacturing the same

InactiveUS20150110667A1High strengthReduce contentFurnace typesMetal rolling arrangementsSheet steelRoom temperature

A high-strength and high-ductility steel sheet having a composition including, by weight, 1.0 to 1.4% C, 5.0 to 9.0% Mn, 2.0 to 8.0% Cr and the balance Fe, and unavoidable impurities. The steel sheet has an austenite structure formed at room temperature, and stacking fault energy is effectively controlled by the addition of Cr and N2. Mechanical twins are formed during the plastic deformation of the steel, thereby leading to high levels of work hardening, tensile strength and workability.

Owner:IND ACADEMIC CORP FOUND YONSEI UNIV

High-forming nitrogen-containing austenitic stainless steel and manufacturing method thereof

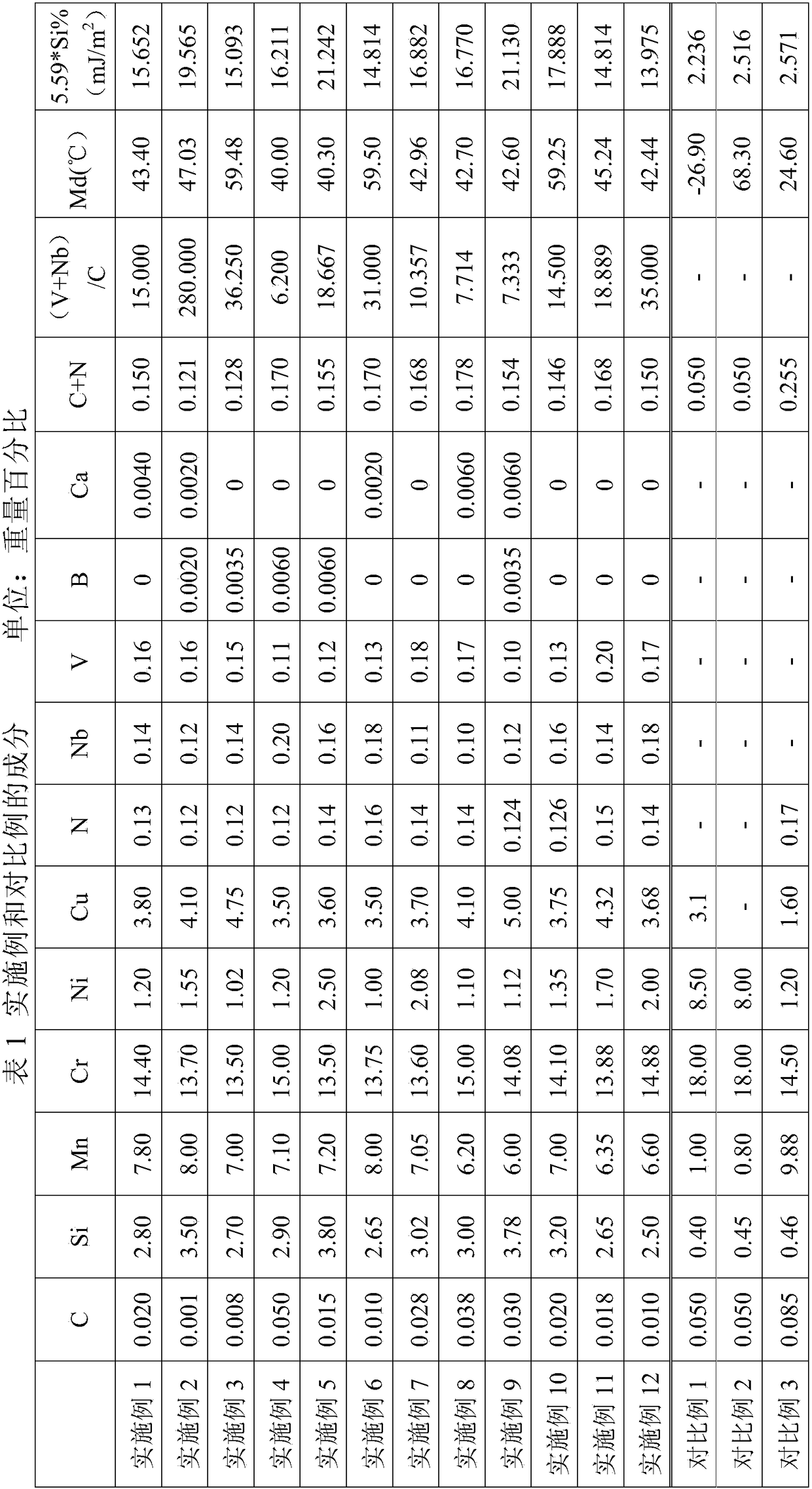

The invention discloses a high-forming nitrogen-containing austenitic stainless steel and a manufacturing method thereof. The composition of the steel comprises the following components of, by weight,0.001-0.05% of C, 2.50-3.80% of Si, 6.0-8.0% of Mn, 13.5-15.0% of Cr, 1.0-2.5% of Ni, 0.12-0.15% of N, 3.5-5.0% of Cu, less than or equal to 0.004% of S, 0.1-0.2% of V, 0.1-0.2% of Nb, and the balance Fe and inevitable impurities, wherein C+N is less than or equal to 0.18% , (V + Nb) / C is larger than or equal to 5, the content of Si multiplied by 5.59 mJ / m<2> is greater than or equal to 14 mJ / m<2>, Md30 / 50 is 40-70 DEG C, the average grain size is larger than or equal to 90 microns, and the hardness is less than or equal to HV180. According to the preparation method disclosed by the invention, the Ni is replaced with nitrogen alloying, and the Mn, the Cu and the like which obtain austenite structures are added; the Si and the like are added, so that lower stacking fault energy is remarkably reduced; the initial hardness of a material is reduced, and the temperature of the MD30 / 50 is controlled, so that the martensite phase changes slowly in the strain process; the erishen value is larger than or equal to 14.5, LDR is larger than or equal to 2.4, the requirements of complex forming is met, and the performance is close to 304 DDQ with high forming and high cost, so that the steel can be widely applied to industries such as electronics, instruments and apparatus, products and the like.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

High-temperature-resisting silver alloy material and preparation method thereof

The invention discloses a high-temperature-resisting silver alloy material. The silver alloy material is prepared through alloy components including, by weight, 80-90 parts of silver, 2-5 parts of copper, 3-5 parts of zinc, 0.2-1 part of cadmium, 0.3-1.2 parts of zirconium, 0.1-0.5 part of indium, 0.2-1 part of beryllium, 0.2-1 part of nickel, 0.3-1.2 parts of magnesium, 0.2-1 part of molybdenum, 0.5-1.5 parts of titanium, 0.3-1.2 parts of cobalt and 0.5-1.5 parts of vanadium. According to the high-temperature-resisting silver alloy material, the stacking fault energy of an alloy matrix is lowered, the diffusion rate of matrix elements is lowered, the effect of strengthening the alloy matrix is achieved, and high temperature resistance of silver alloy is improved; and in the production process, high temperature losses are reduced, and the production cost is greatly reduced.

Owner:无棣向上机械设计服务有限公司

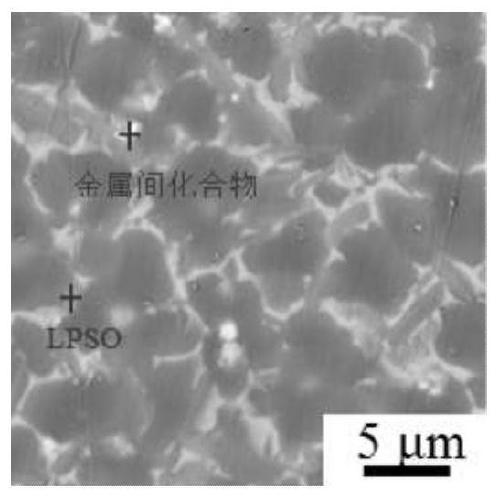

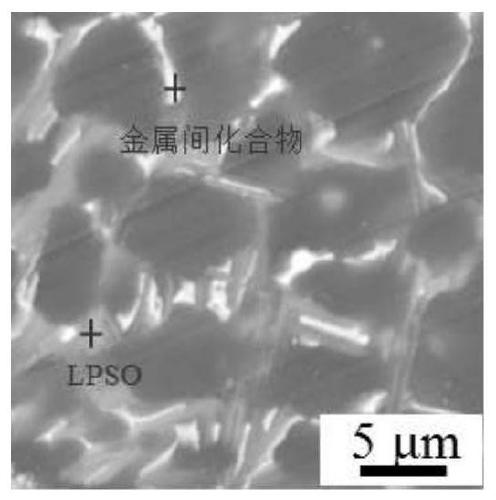

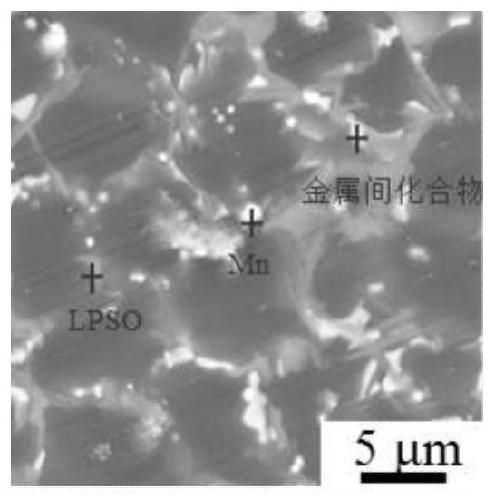

Biological magnesium alloy containing rich LPSO structures and preparing method of biological magnesium alloy

ActiveCN110064750AImprove resistance to degradationAdditive manufacturing apparatusIncreasing energy efficiencyManganeseStacking-fault energy

The invention discloses a biological magnesium alloy containing rich LPSO structures and a preparing method of the biological magnesium alloy. The biological magnesium alloy is obtained in the mannerthat manganese is alloyed to a magnesium alloy with the LPSO structures through an SLM technology, on one hand, the magnesium alloy stacking fault energy is reduced through the manganese element, andintermetallic compound precipitation is reduced while the number of the LPSO structures is increased; and on the other hand, the alloy supercooling degree is increased through the manganese element, grains and the LPSO structures are refined, and the magnesium alloy with the rich, fine and evenly-distributed LPSO structures is obtained. A base body is full of the formed LPSO structures in a parallel lamellar manner, a dense degraded product is formed through preferable degrading, the magnesium base body is protected, and accordingly the degrading resistance of the magnesium alloy is greatly improved.

Owner:JIANGXI UNIV OF SCI & TECH +1

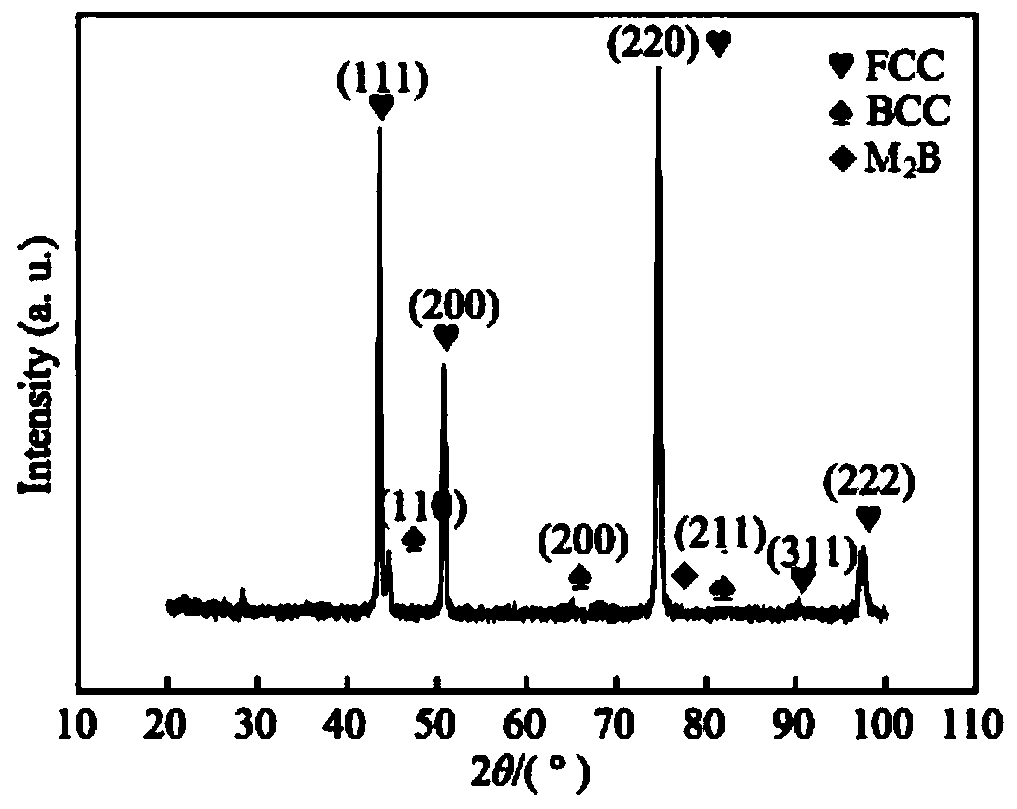

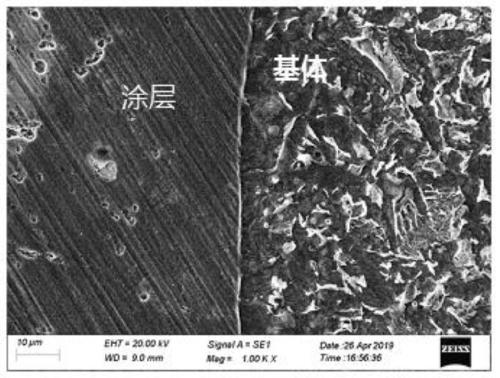

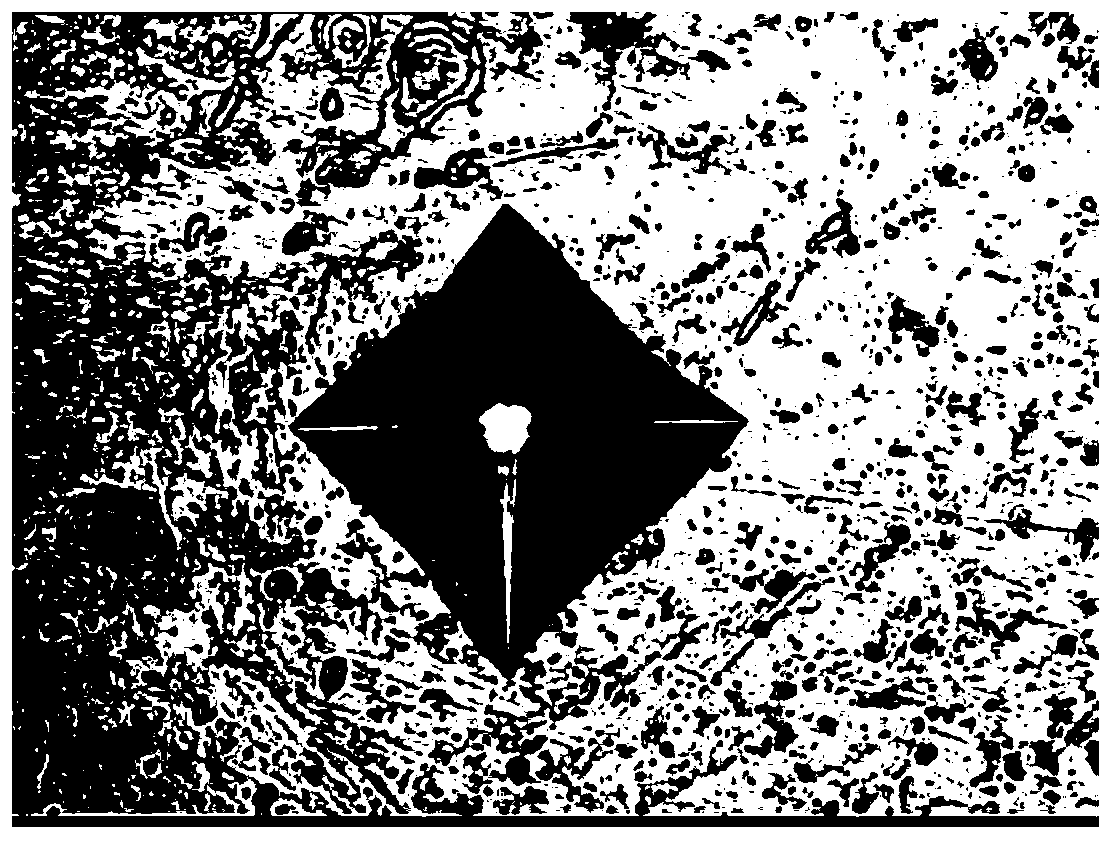

Boron-containing high-entropy alloy coating and preparation method thereof

InactiveCN110273153AIncrease the solid solution limitImprove distortionMetallic material coating processesBorideHigh entropy alloys

The invention provides a boron-containing high-entropy alloy coating and a preparation method thereof, and belongs to the field of alloy coatings. Some B atoms are adopted as self-fluxing atoms to be subjected to solid solution in a solid solution body of the face-centered cubic structure, the hardness of the coating is improved, granular and short rod-like M2B hard phases are separated out in a coating base, and due to separation of the hard phases, one one hand, the dispersion strengthening effect is achieved; on the other hand, the solid solution reinforcing effect is lowered, the coating hardness is lowered, and due to the hardness improving effect of dispersion strengthening, solid phase strengthening is greatly offset, the influence of the coating hardness is lowered, finally, the coating hardness is still improved, and a boron element is adopted as a secondary element to be added into high-entropy alloy; due to the gap effect of non-metal elements, the alloy stacking fault energy is improved, lattice deformation is increased, the solid solution strengthening effect is achieved, the non-metal element and the main element can form borides to be dispersed into alloy tissue, the dispersion strengthening effect is generated, and therefore the hardness and corrosion resistance of the high-entropy alloy are improved.

Owner:NANCHANG UNIV +1

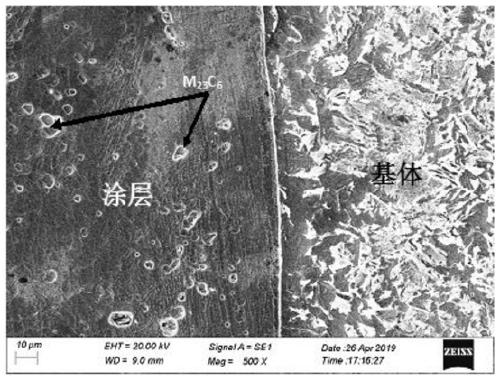

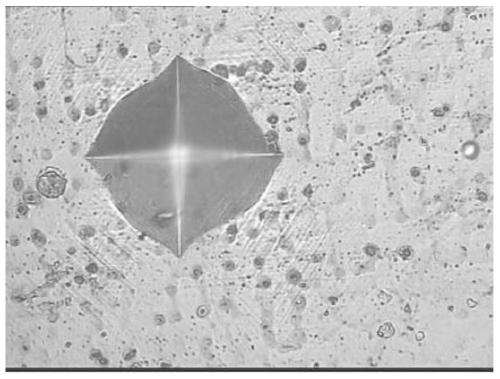

Carbonic high-entropy alloy coating and preparation method thereof

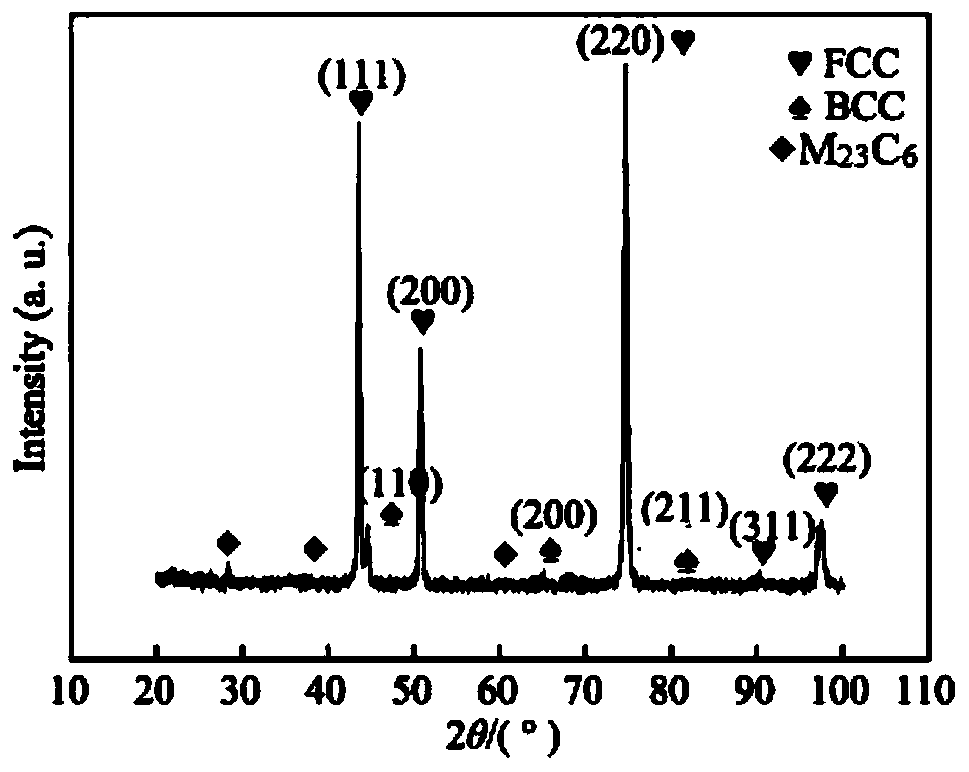

ActiveCN110241354ALarge lattice distortionHigh hardnessMetallic material coating processesHigh entropy alloysCarbide

The invention provides a carbonic high-entropy alloy coating and a preparation method thereof, and belongs to the field of alloy coatings. Co, Cr, Cu, Fe and Mn are adopted as main elements, a carbon element (C) is adopted as a secondary element, C is an interval element and is added into the CoCrCuFeMn high-entropy alloy, the stacking fault energy of the alloy can be improved through the interval effect of the non-metal element, lattice distortion of the high-entropy alloy is improved, the solid solution strengthening effect is achieved, the carbon element can form a carbide with the main elements, for example, Fe-C, Cr-C M23C6 or M7C3 carbides are formed and dispersed into alloy tissue, the dispersion reinforcing effect is generated, and the high-entropy alloy hardness and abrasion resistance are improved; meanwhile, the high-entropy alloy structure formed by the main elements is BCC+FCC, a dual-phase solid solution is formed, after the C element is added, and the phase structure type cannot change; due to the dual-phase solid solution, the high-entropy alloy has the higher strength, and the hardness of the carbonic high-entropy alloy coating is improved.

Owner:NANCHANG UNIV

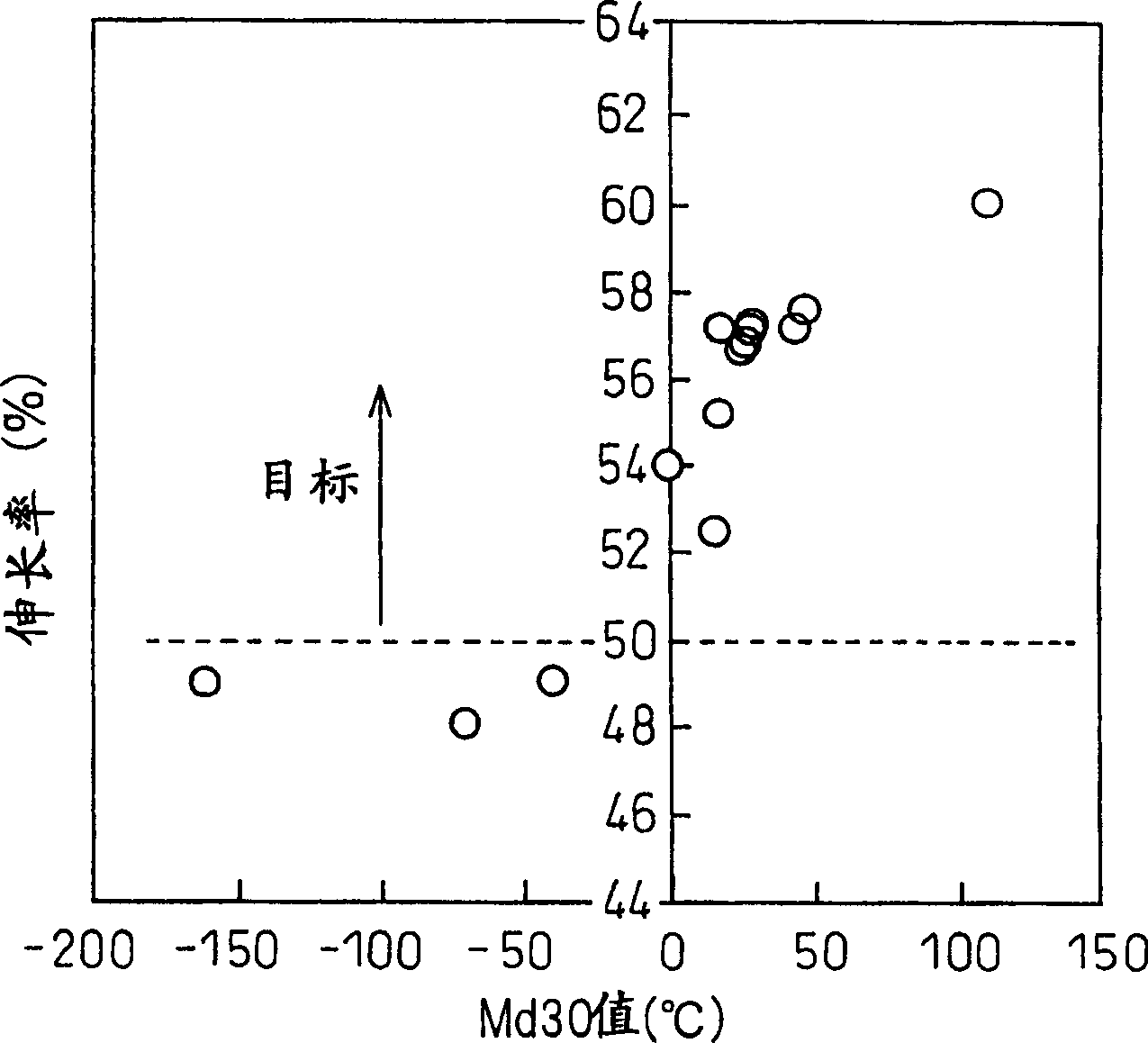

Austenitic high mn stainless steel excellent in workability

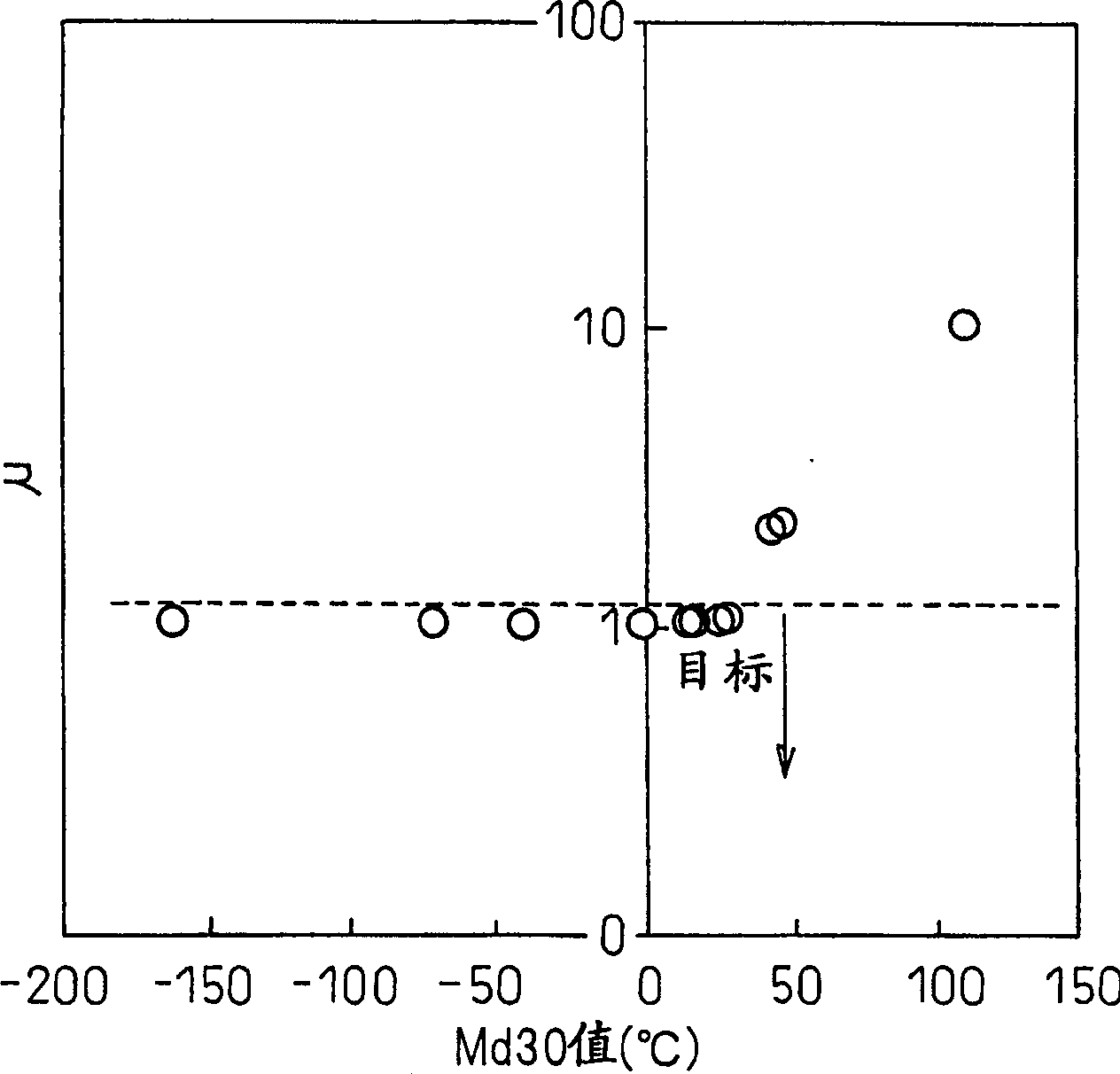

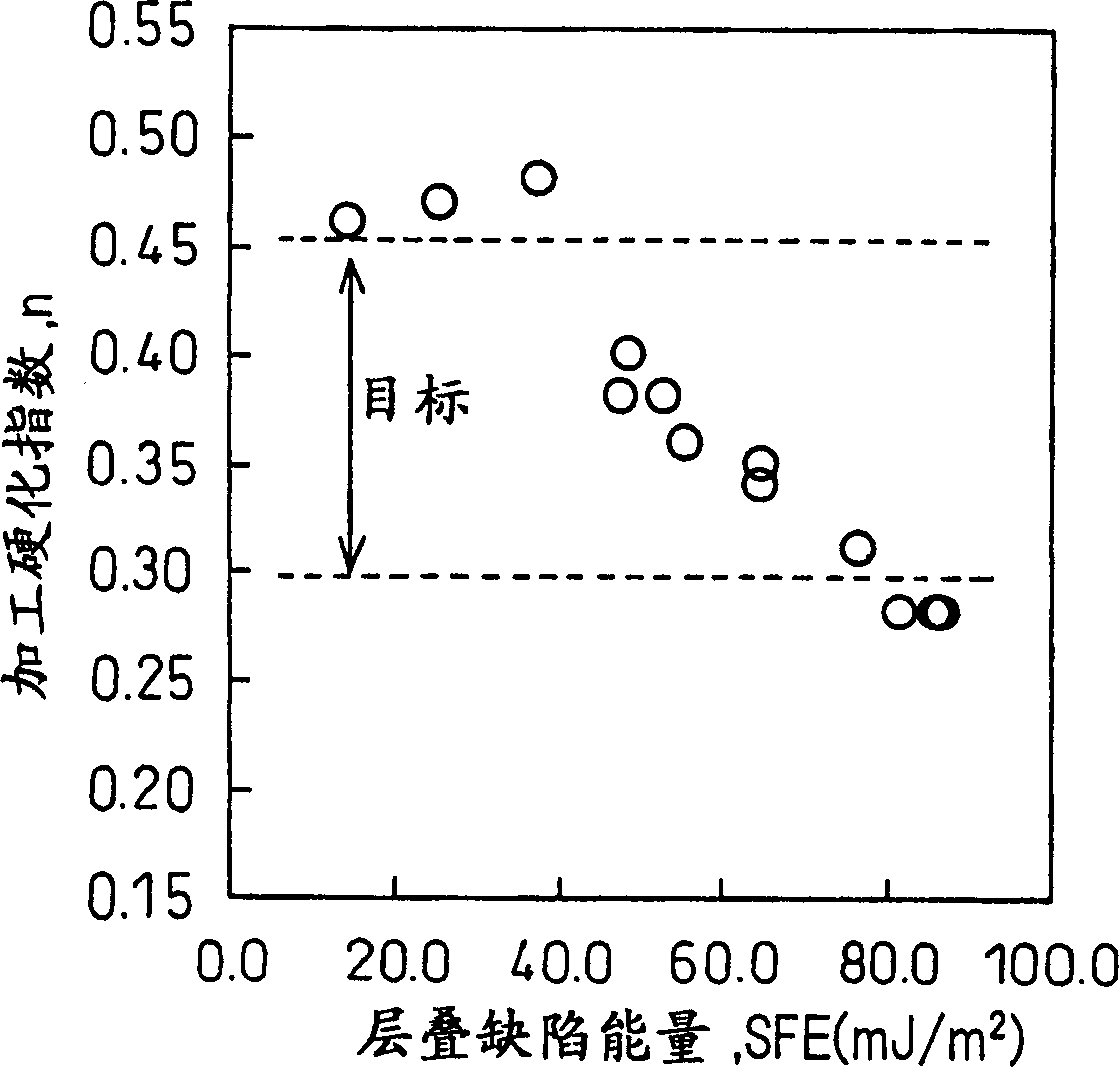

The present invention aims to provide an austenitic stainless steel that improves the workability of high-Mn stainless steel and maintains non-magnetic properties after processing, and includes C+N: 0.03 to 0.15% and Si: 0.1% by mass. ~1%, Mn: 3~15%, Cr: 10~16%, Ni: 1~6%, Cu: 0.3~3%, Mo: 0.3~3%, the rest is Fe and unavoidable impurities, And the composition design is carried out in such a way that the index Md30 value of austenite stability and the generation index SFE of lamination defect energy meet the following conditions: -10<Md30<30, 40<SFE<80Md30 (°C): 497-462 (C+ N)-9.2Si-8.1Mn-13.7Cr-20 (Ni+Cu)-18.5MoSFE [mJ / m2]: 6.2Ni+18.6Cu+0.7Cr+3.2Mn+9.3Mo-53.

Owner:NIPPON STEEL & SUMIKIN STAINLESS STEEL CORP

High manganese nitrogen-containing steel sheet having high strength and high ductility, and method for manufacturing the same

InactiveUS20120045358A1Effective supervisionImprove machinabilityElectric furnaceHeat treatment furnacesManganeseAustenite

Provided is a high manganese nitrogen-containing steel sheet. The high manganese nitrogen-containing steel sheet according to the present invention comprises 0.5 to 1.0 wt % of carbon, 10 to 20 wt % of manganese, 0.02 to 0.3 wt % of nitrogen, with a remainder of Fe and unavoidable impurities. The high manganese nitrogen-containing steel sheet according to the present invention produces an austenite phase at room temperature, in which the stacking fault energy is effectively controlled by adding chrome and nitrogen. Accordingly, the high manganese nitrogen-containing steel sheet of the present invention produces a mechanical twin during the plastic deformation of the steel sheet, thereby increasing the work hardening rate, tensile strength, and workability.

Owner:HYUNDAE STEEL CO LTD

Steel for low-temperature service having excellent surface processing quality

InactiveUS20160319407A1Improve surface finish qualityHigh energyFurnace typesMetal rolling arrangementsNitrogenManganese

Steel for low-temperature service having a high degree of surface processing quality comprises: manganese (Mn): 15 wt % to 35 wt %, carbon (C) satisfying conditions of: 23.6C+Mn≧28 and 33.5C−Mn≦23, copper (Cu): 5 wt % or less (excluding 0 wt %), nitrogen (N): 1 wt % or less (excluding 0 wt %), chromium (Cr) satisfying a condition of: 28.5C+4.4Cr≦57, nickel (Ni): 5 wt % or less, molybdenum (Mo): 5 wt % or less, silicon (Si): 4 wt % or less, aluminum (Al): 5 wt % or less, and a balance of iron (Fe) and inevitable impurities. Stacking fault energy (SFE) of the steel is 24 mJ / m2 or greater. The SFE is calculated by a formula: SFE (mJ / m2)=1.6Ni−1.3Mn+0.06Mn2−1.7Cr+0.01Cr2+15Mo−5.6Si+1.6Cu+5.5Al−60(C+1.2N)1 / 2+26.3(C+1.2N)(Cr+Mn+Mo)1 / 2+0.6[Ni(Cr+Mn)]1 / 2.

Owner:POHANG IRON & STEEL CO LTD

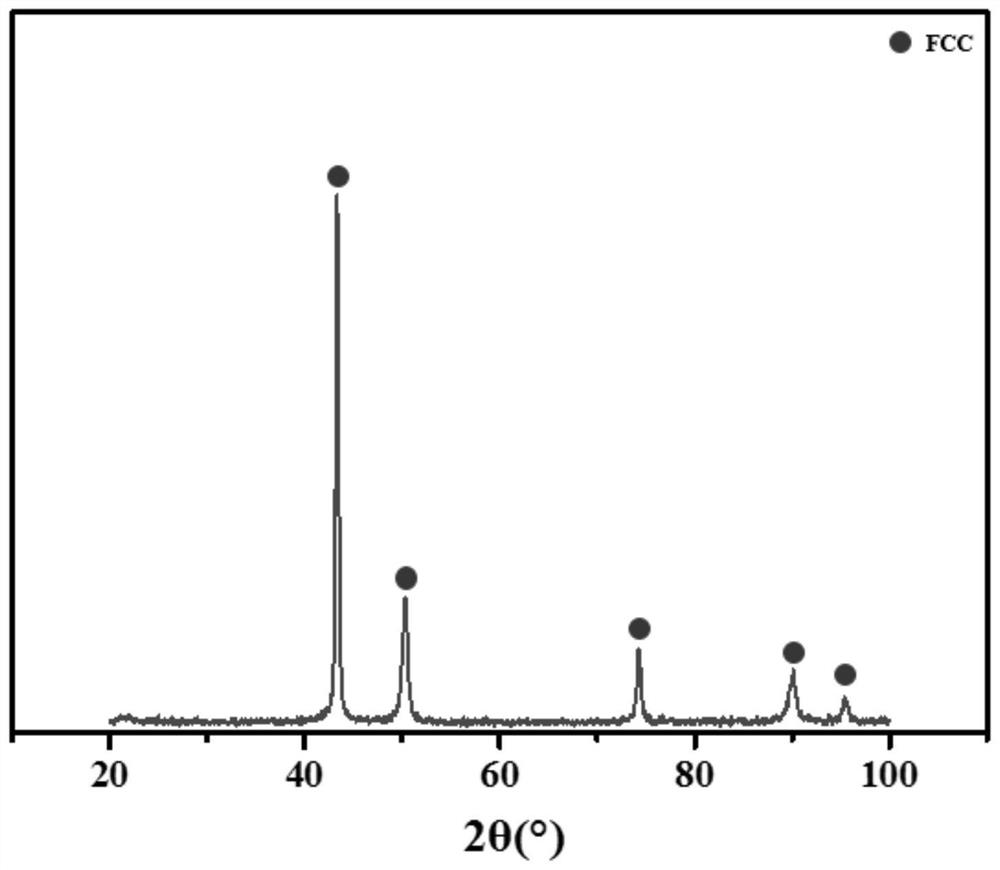

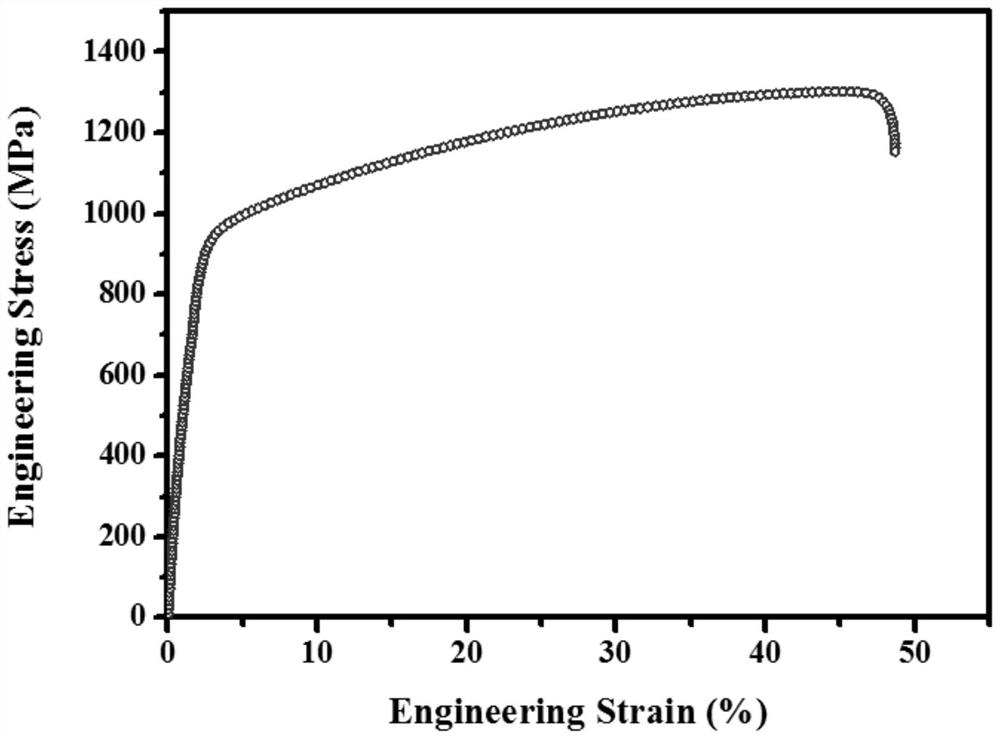

High-plasticity and high-strength high-entropy alloy and preparation method thereof

ActiveCN113430444AReduce stacking fault energyHigh strengthFurnace typesMetal rolling arrangementsAviationHigh entropy alloys

The invention discloses a high-plasticity and high-strength high-entropy alloy and a preparation method thereof. The expression of the high-entropy alloy is NiaCobFecNbdVe, and a, b, c, d and e in the expression of the alloy respectively represent the atomic percentage content of each corresponding principal element and meet the following conditions that a is 40-30, b is 35-25, c is 35-25, d is 10-3, e is 10-3, and the sum of a, b, c, d and e is equal to 100. According to the high-entropy alloy, stacking fault energy of the alloy and the precipitation volume fraction of a nano precipitated phase are regulated and controlled by adjusting the content of each principal element, so that high plasticity and high strength are obtained. The yield strength of the high-entropy alloy reaches 1000 MPa, the tensile strength can reach 1300 MPa, and the ductility reaches up to 50%. The high-strength and high-plasticity high-entropy alloy can be used in the key high-technology fields of nuclear power, aviation, aerospace, navigation and the like.

Owner:HARBIN ENG UNIV

High strength superfine crystalloid copper-germanium alloy and preparation method thereof

The invention provides a high strength superfine crystalloid copper-germanium alloy and a preparation method thereof. The high strength superfine crystalloid copper-germanium alloy consists of the following components in percentage by mass: 99.89 to 89.85 percent of copper, and 0.11 to 10.15 percent of germanium. The preparation method comprises the following steps of: mixing pure copper and pure germanium in the proportion, smelting, and casting into a copper-germanium alloy bar; performing vacuum annealing, and forging; performing vacuum annealing again to obtain a homogenous microstructure; and immersing in liquid nitrogen for cooling, and forging to obtain the deformation twins-containing high-strength superfine crystalloid copper-germanium alloy. The stacking fault energy of the copper is reduced by adding the germanium element, and a large quantity of deformation twins are introduced, so that the copper-germanium alloy has high strength and excellent mechanical properties. Through the simple preparation process, the copper-germanium alloy with the tensile strength at room temperature of 467-802MPa can be obtained.

Owner:KUNMING UNIV OF SCI & TECH

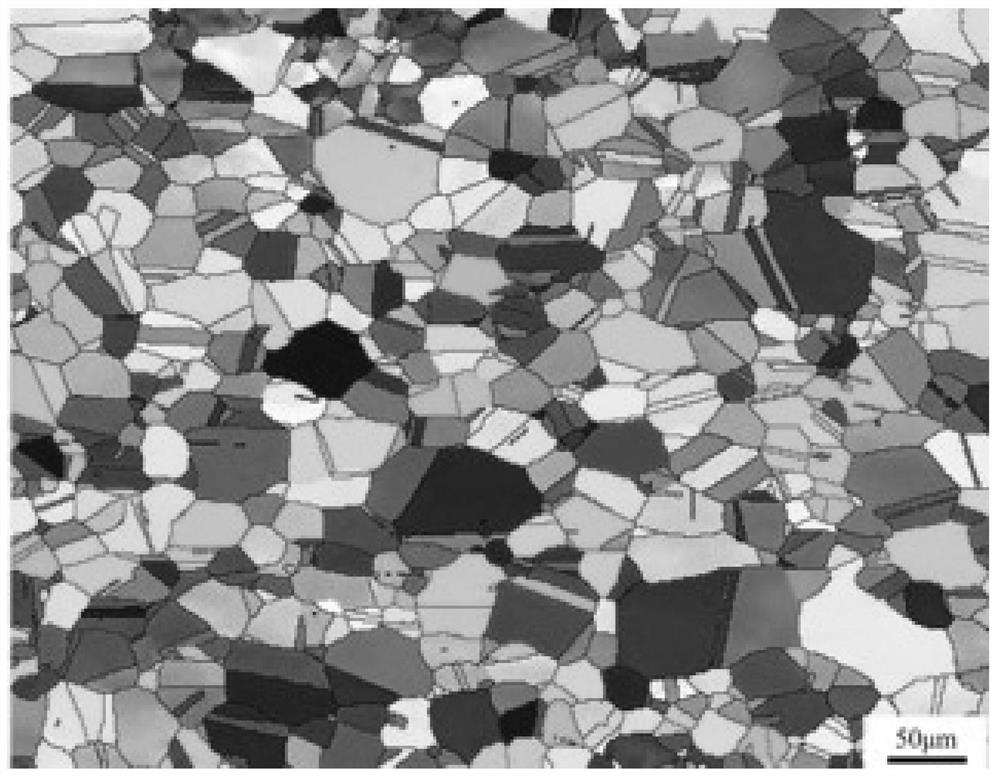

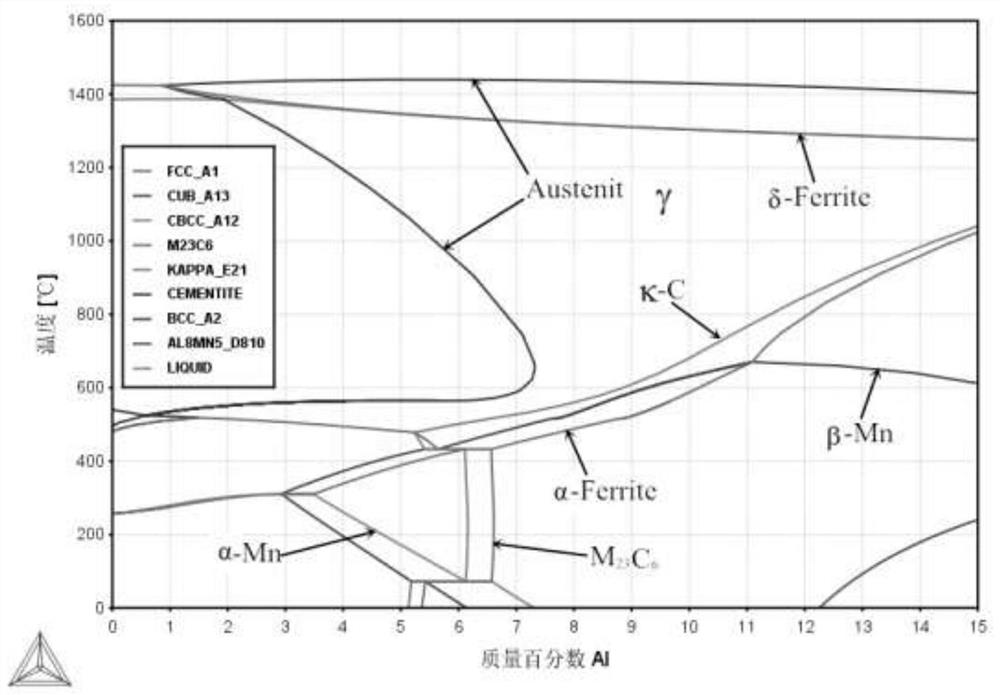

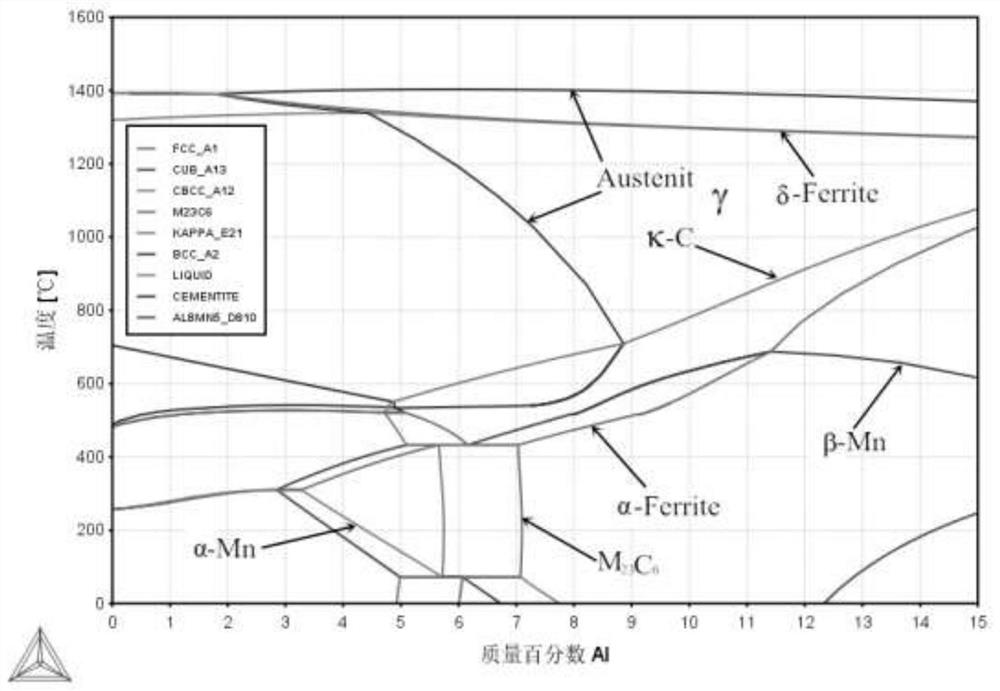

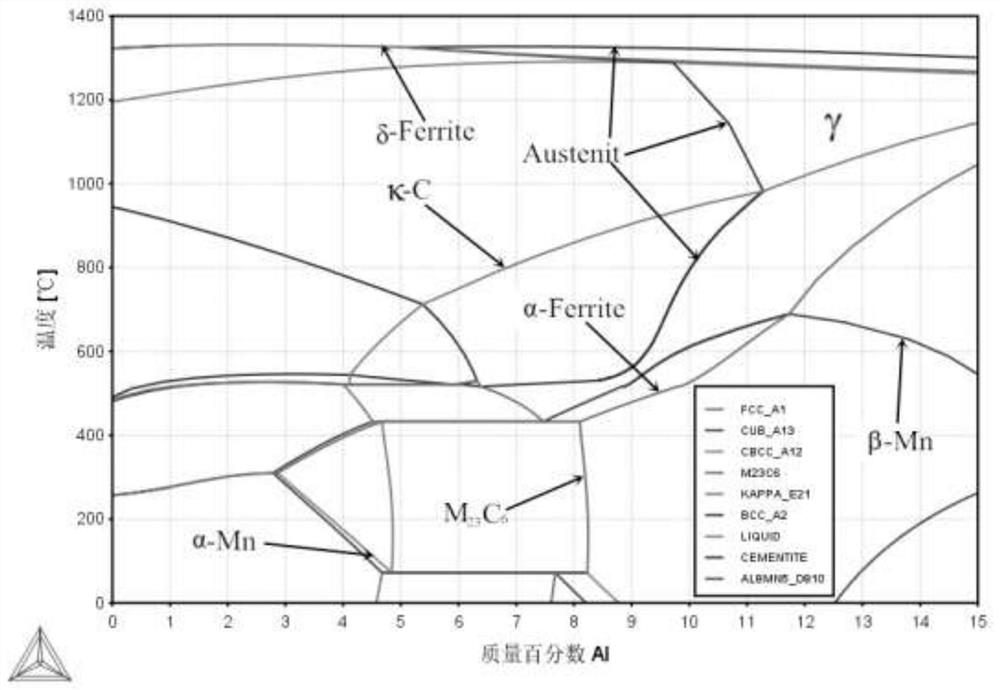

Component optimization design method of austenite Fe-Mn-Al-C light alloy steel

PendingCN113373383APredictable deformation mechanismContent Adjustment OptimizationChemical compositionCarbide

The invention discloses a component optimization design method of austenite Fe-Mn-Al-C light alloy steel, and relates to the technical field of metal materials. The component optimization design method comprises the steps that S1, typical chemical components are formulated; S2, thermodynamic and phase diagram calculation is carried out; S3, a corresponding relation graph of the precipitation temperature and calculated SFE is drawn; S4, the chemical components of the alloy are optimized; and S5, chemical component and experiment detection is carried out. The typical chemical components of the alloy steel are formulated on the basis of the chemical component range limited by the austenite Fe-Mn-Al-C light alloy steel, an Olson-Cohen thermodynamic model is selected to calculate the stacking fault energy (SFE) of the typical alloy steel, all the chemical components are optimized, a deformation mechanism of materials can be predicted through the method, the generation content and precipitation temperature of kappa-C carbide are controlled, the strengthening effect of the kappa-C carbide on the austenite light steel is achieved, and a theoretical basis is provided for alloy design and production.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

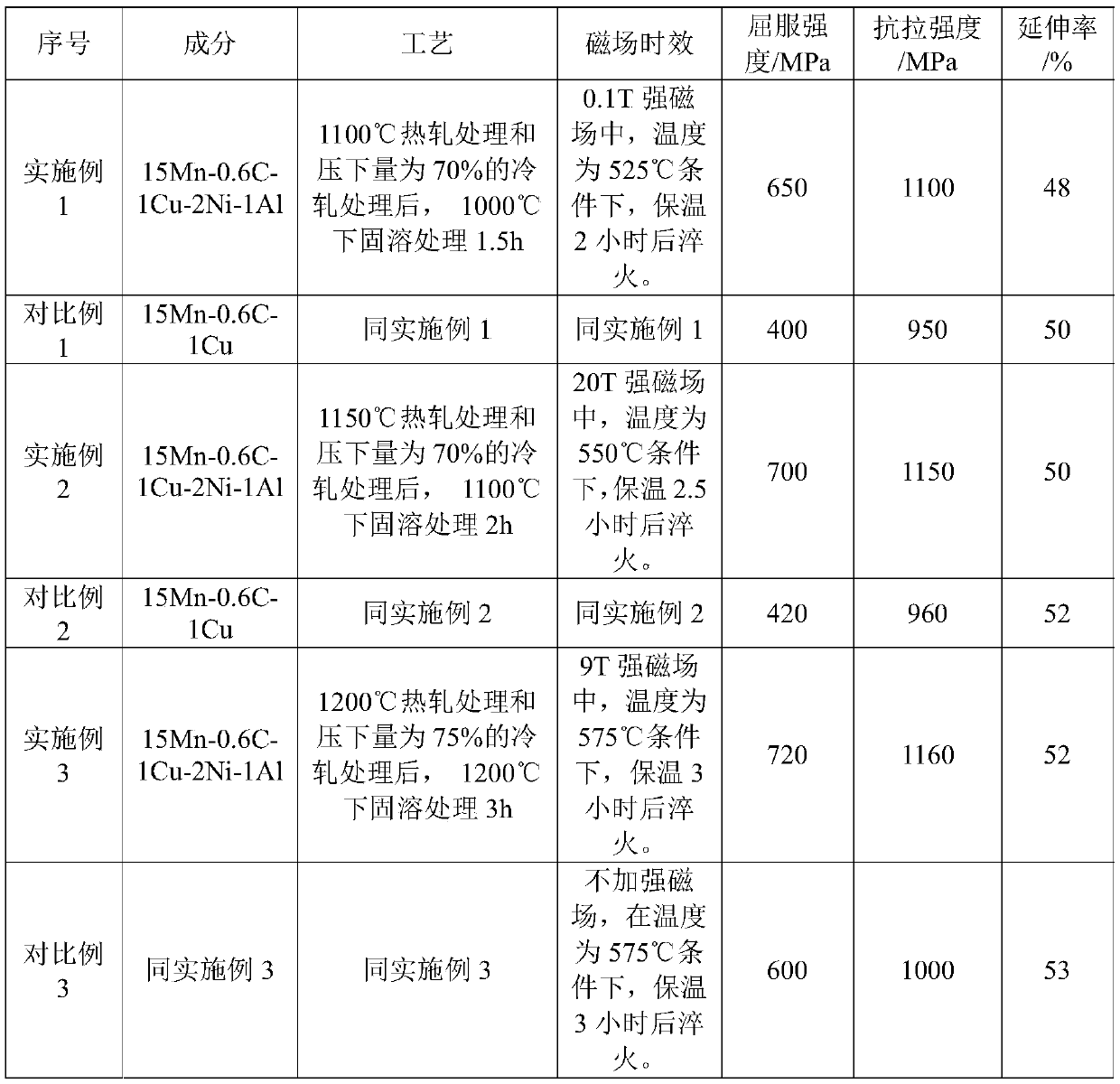

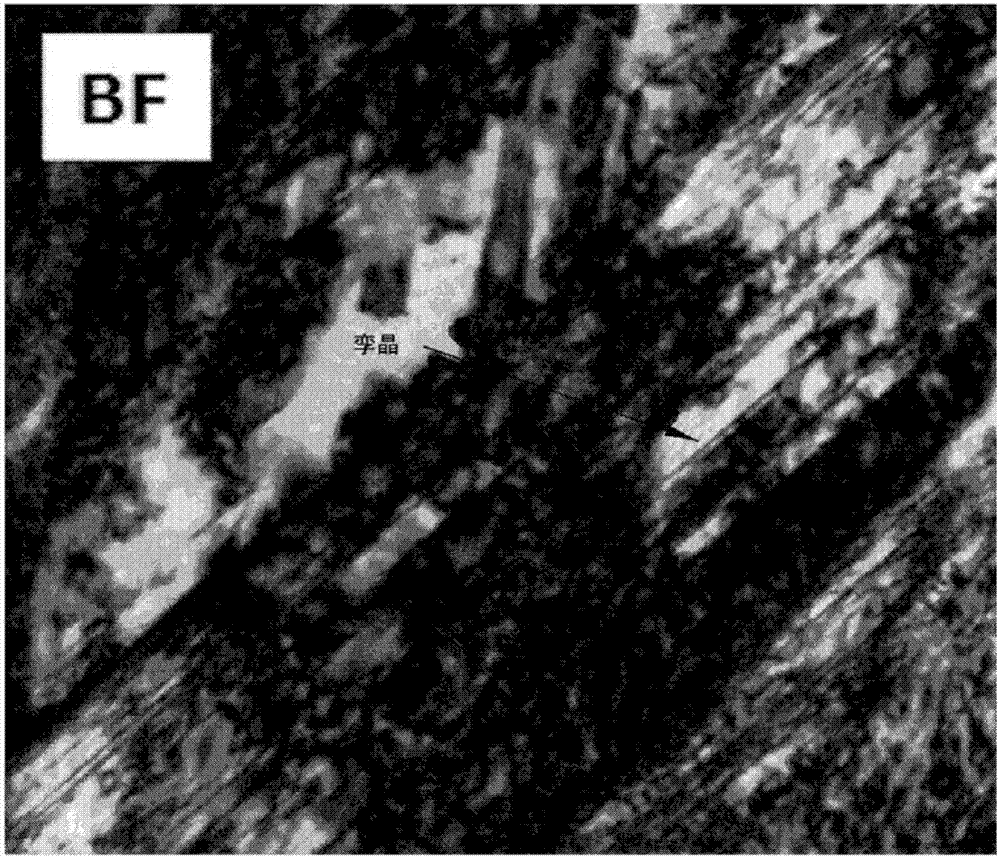

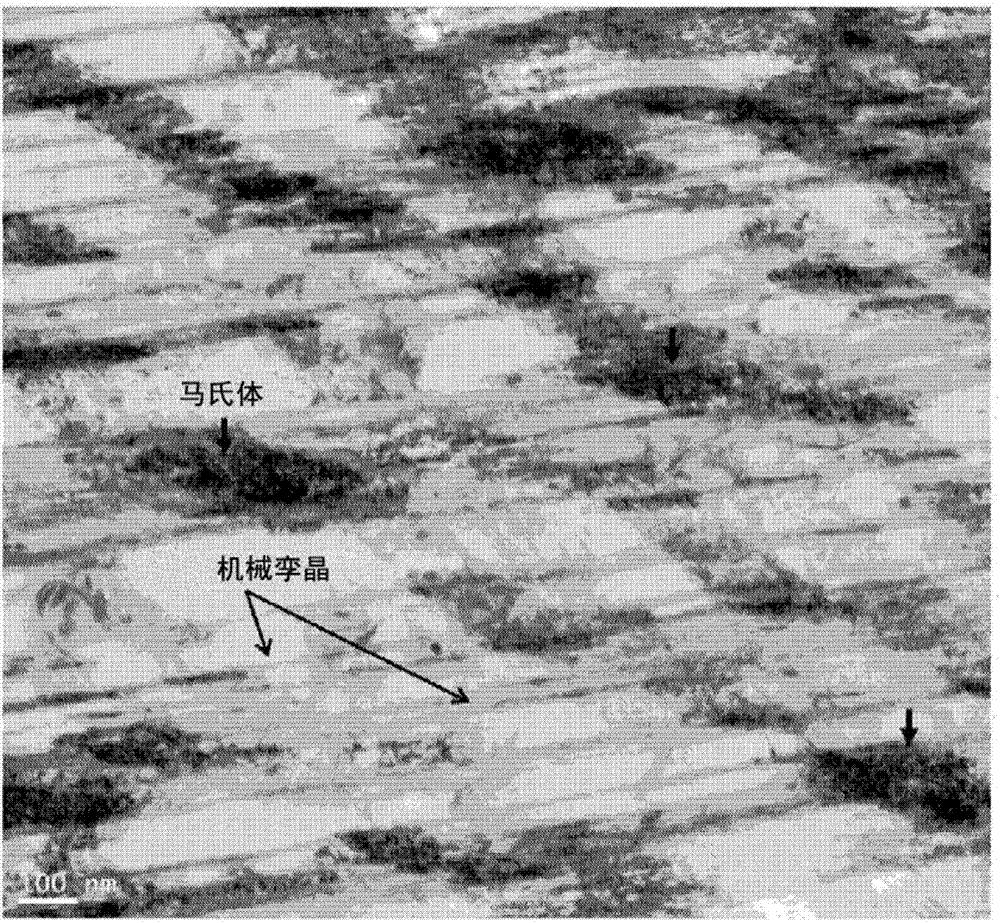

TWIP steel and preparation method thereof

The invention provides high-strength high-plasticity TWIP steel and a preparation method thereof. The technical scheme is that: aimed at the defects that higher strength and higher plasticity are notliable to achieve through single of twinning strengthening and nano precipitation strengthening in steel, the invention provides the preparation method of utilizing alloy elements like Cu, Ni and Al to replace a part of Mn to improve stacking fault energy, promote the TWIP effect, stabilize austenite, inhibit martensite phase transformation and refine twining structure on the basis that smelting,homogenization and delayed cracking problems due to high Mn content in TWIP steel are comparatively studied; and size, density and distribution of nano rich Cu particles and NiAl particles generated in steel are controlled through a strong magnetic field, and strength of TWIP steel is improved under the precondition that plasticity and toughness are not reduced.

Owner:NORTHEASTERN UNIV

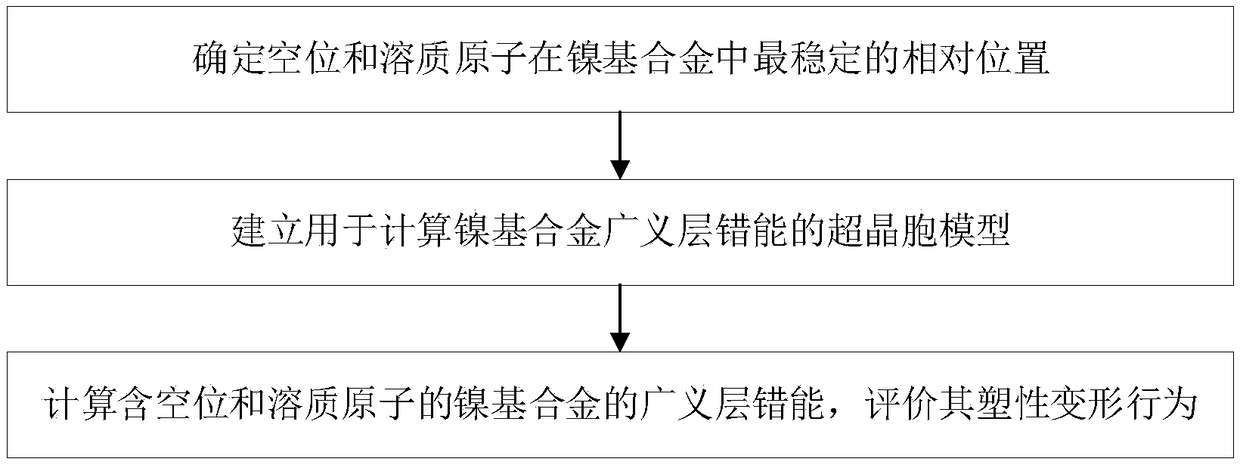

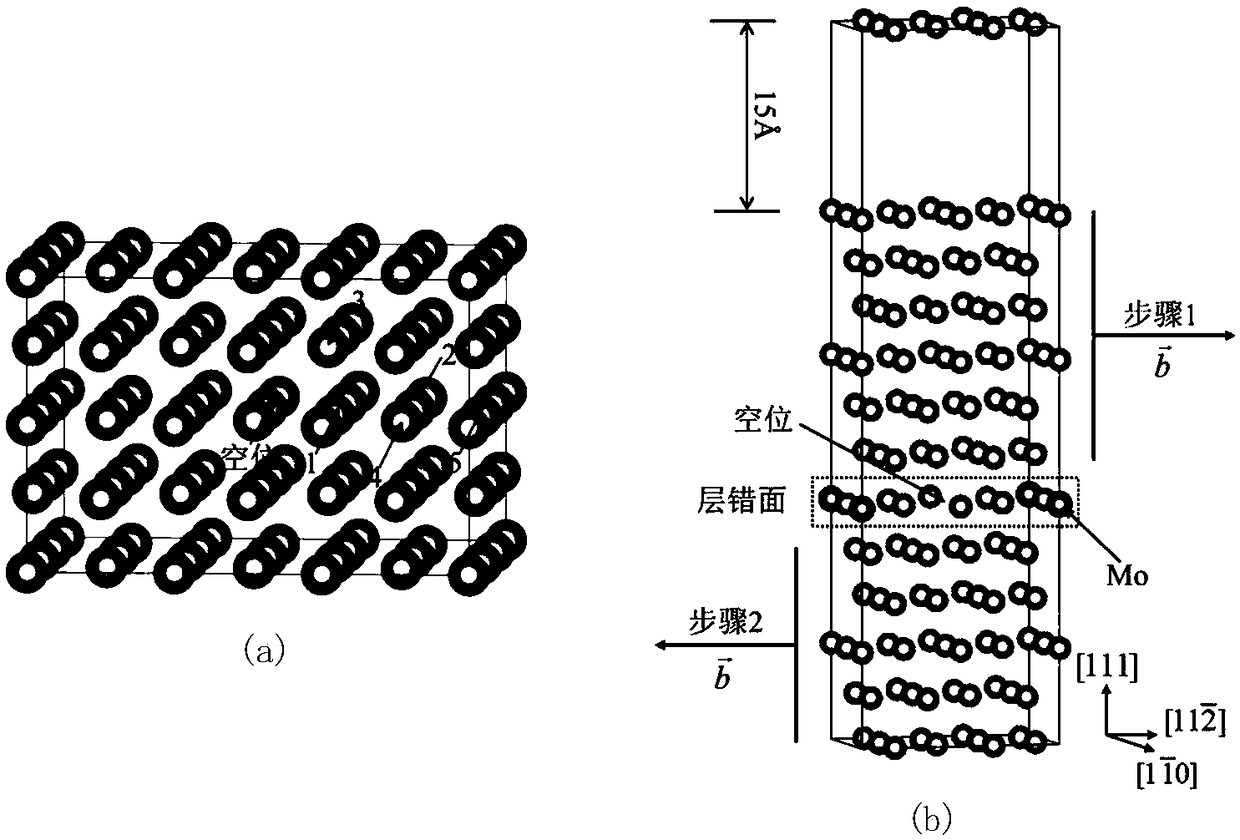

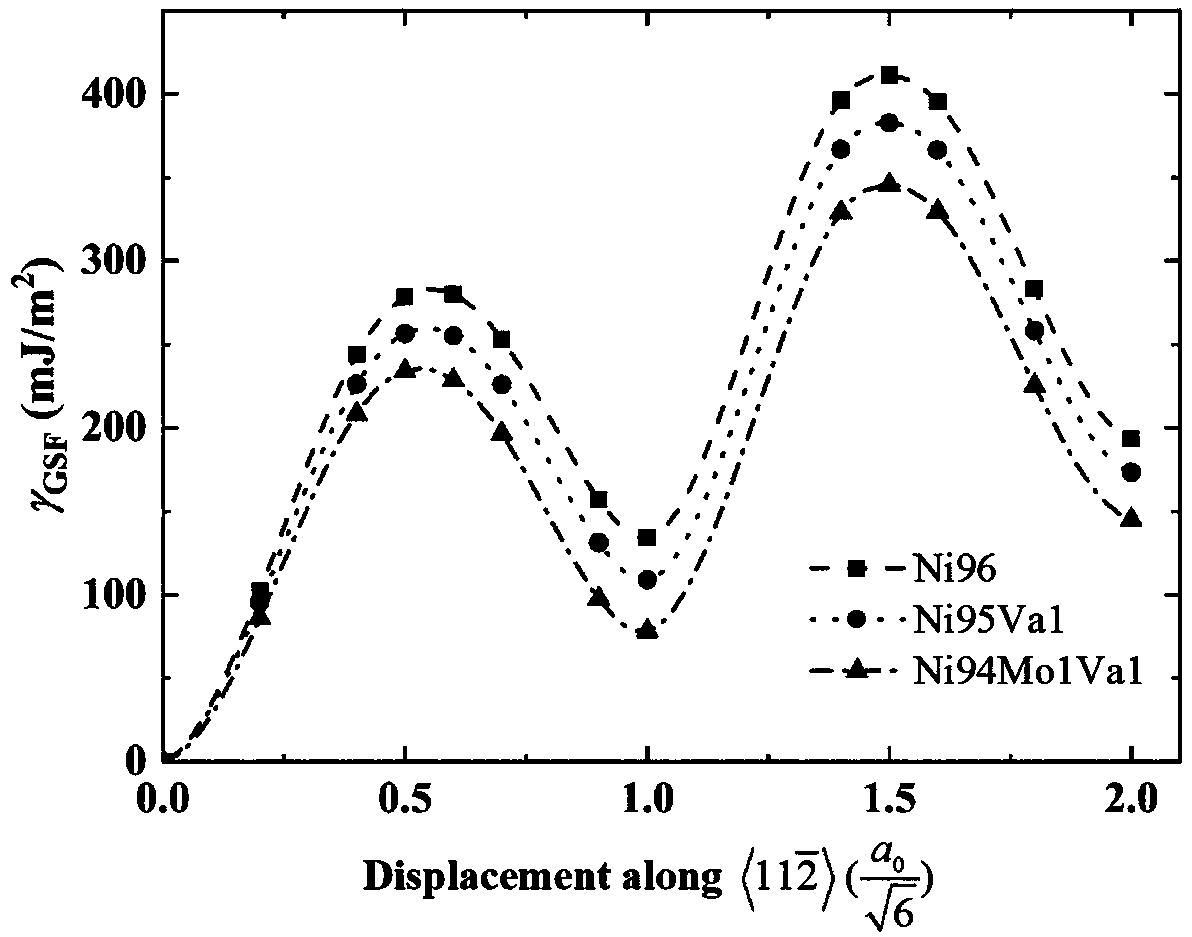

A method for evaluating the deformability of a nickel-based alloy containing composite point defects

ActiveCN109086507APrevent bias in calculation resultsImprove computing efficiencyDesign optimisation/simulationSpecial data processing applicationsComputation processJoint influence

A method for evaluating the deformability of a nickel-based alloy containing composite point defects. Considering the influence of vacancy and solute atoms on the generalized stacking fault energy ofnickel-based alloys, Fully considering the establishment of supercell model, the deformability of Ni-based alloys with composite point defects is evaluated by the calculation of generalized stacking fault energy. The method includes the following steps: firstly, determining the most stable relative positions of vacancies and solute atoms in Ni-based alloys; secondly, establishing a supercell modelfor calculating that generalize stacking fault energy of the nickel-based alloy; thirdly, the generalized stacking fault energy of Ni-based alloys containing vacancies and solute atoms being calculated; in the fourth step, the plastic deformation behavior is evaluated according to the generalized stacking fault energy. The invention fully considers the important parameters which can influence thestructure model when establishing the model, including the vacuum layer thickness, the atomic layer number and the relaxation system, effectively prevents the calculation result deviation caused by the unreasonable structure model in the calculation process of the generalized stacking fault energy, improves the calculation efficiency and reduces the calculation cost.

Owner:BEIHANG UNIV

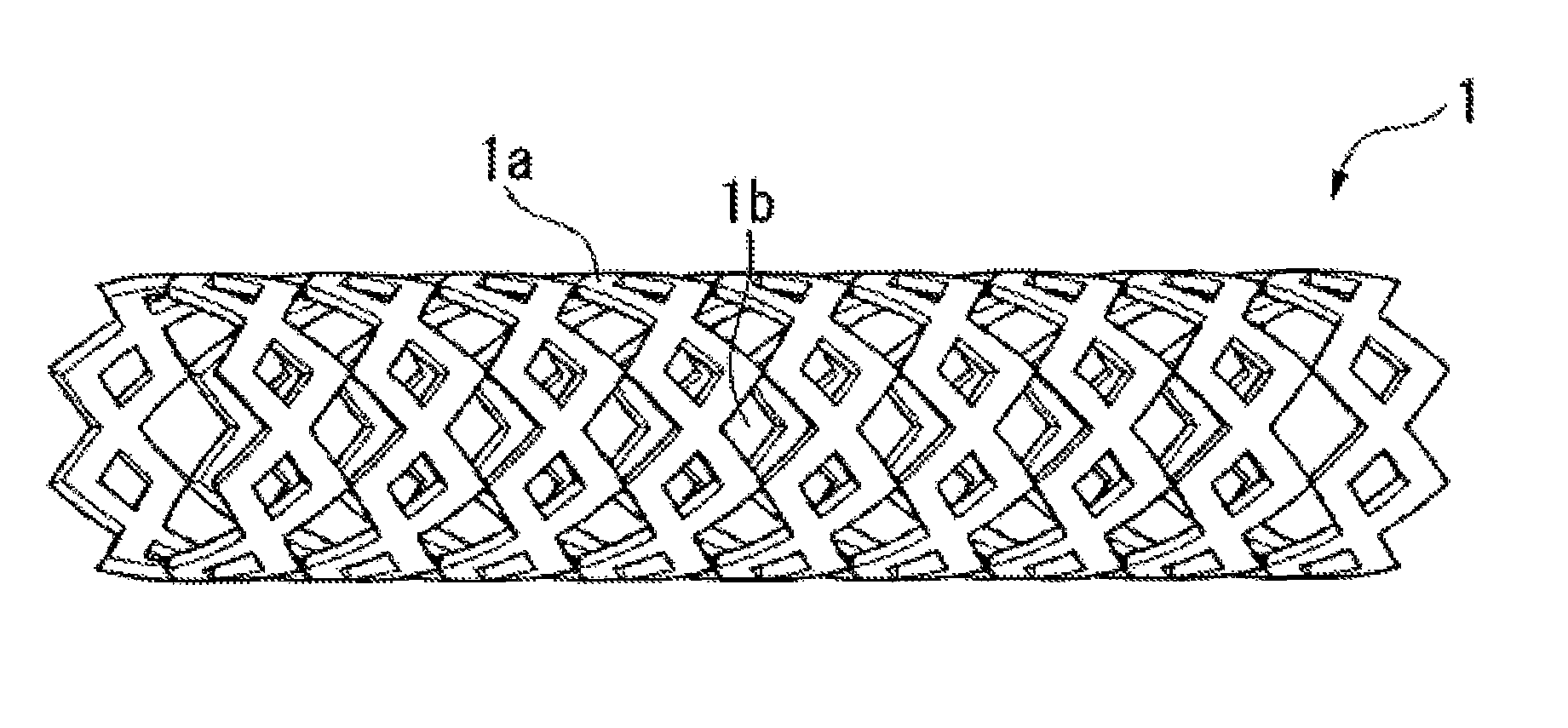

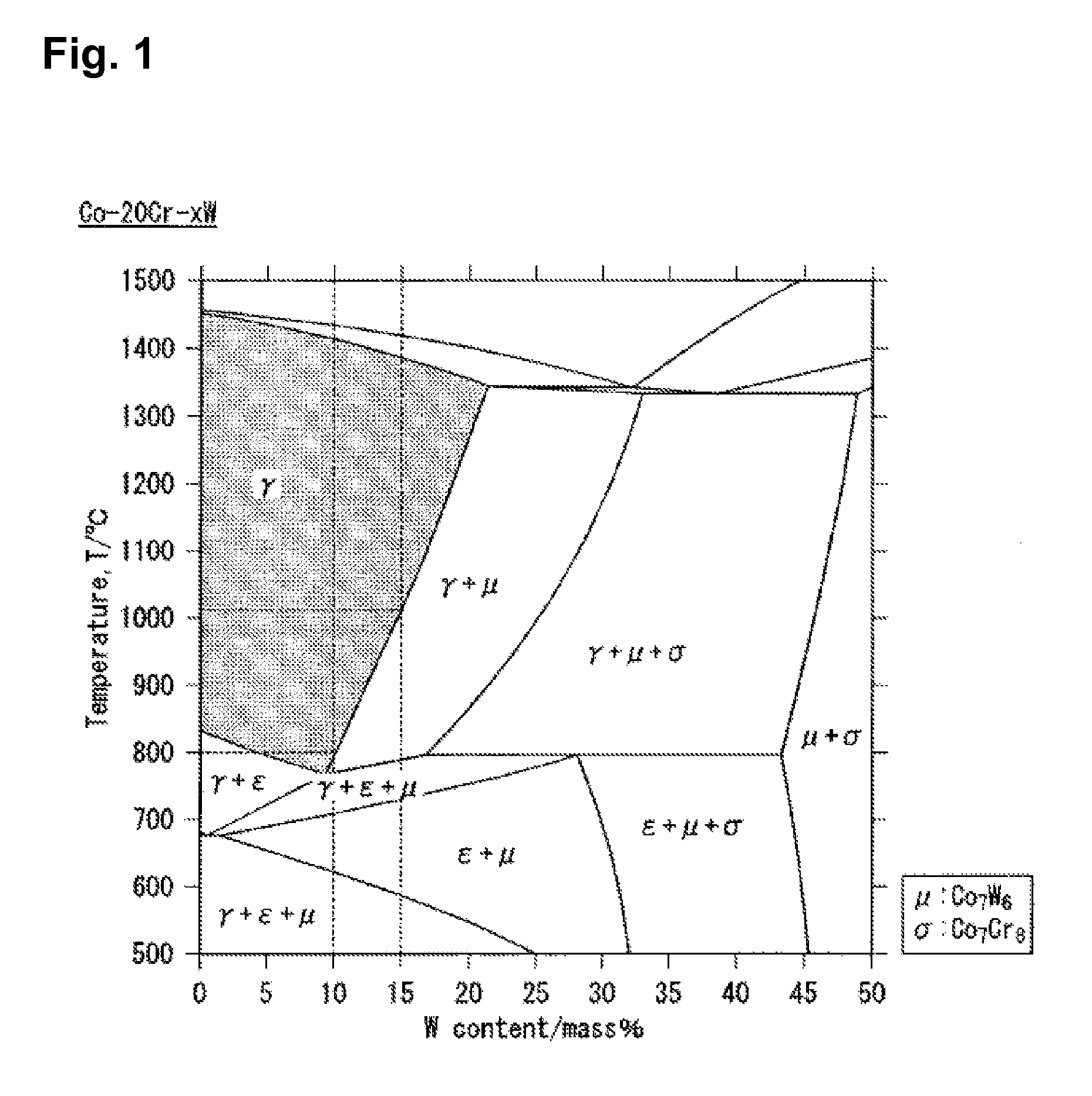

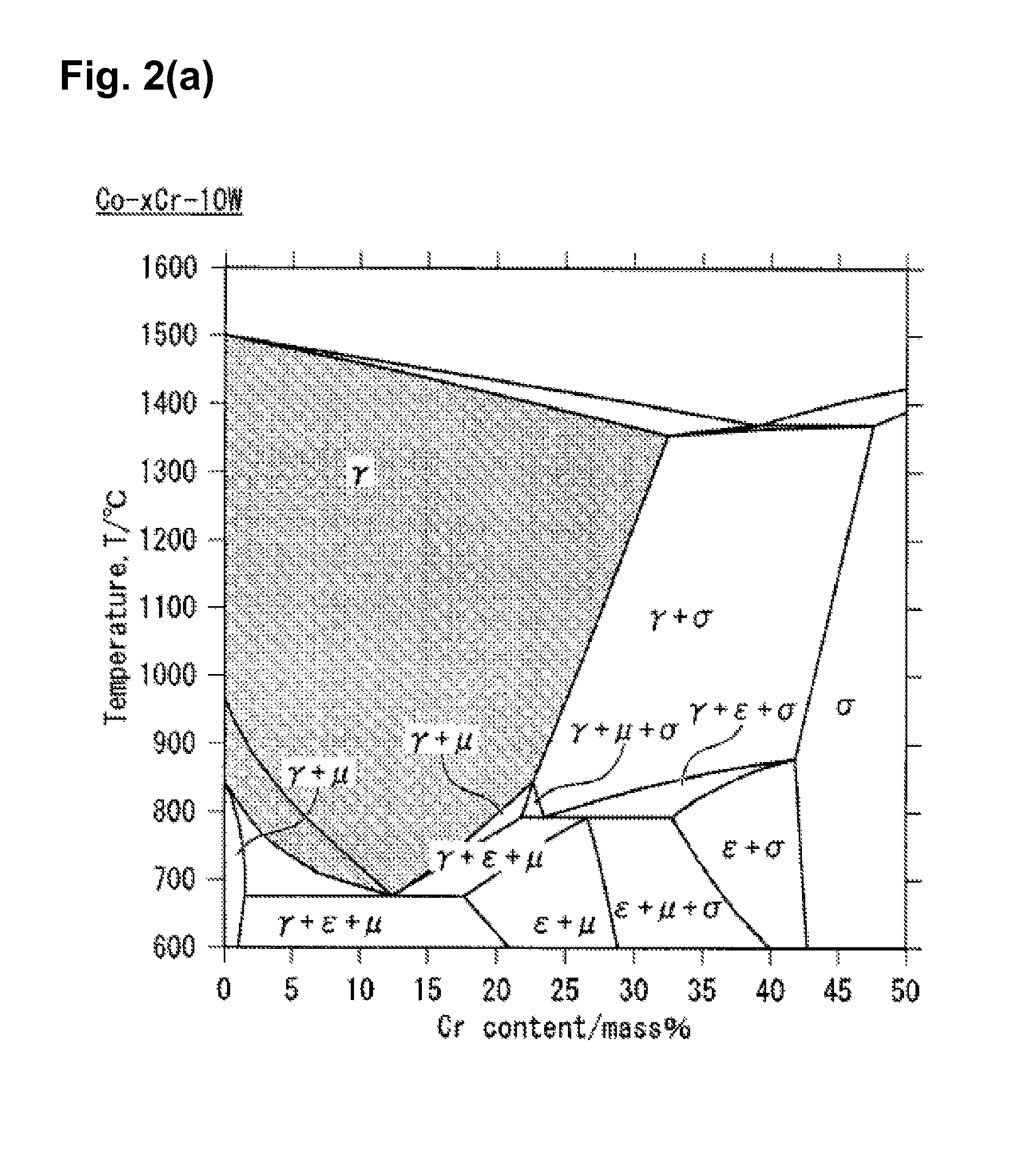

Co-based alloys for biomedical applications and stent

InactiveUS9260769B2Improve plastic processing performanceLower performance requirementsStentsSurgeryVisibilityInsertion stent

A first object of the present invention is to provide Co-based alloys for biomedical applications which are Ni-free, high intensity and high elastic modulus and are suitable for plastic workability. Moreover, a second object of the present invention is to provide Co-based alloys for biomedical applications having X-ray visibility. Furthermore, a third object of the present invention is to provide a stent using the alloys. The Co-based alloys for biomedical applications according to the present invention is configured by adding alloy elements having biocompatibility and an effect of increasing stacking fault energy of the alloys.

Owner:SEIKO INSTR INC +1

Lean duplex stainless steel and method for producing same

The present invention relates to lean duplex stainless steel having a dual-phase structure of an austenite phase and a ferrite phase, and a method for producing the lean duplex stainless steel, the lean duplex stainless steel according to one embodiment of the present invention, as a ferrite-austenite stainless steel, having the preferred stacking fault energy (SFE) value of the austenite phase, expressed by the formula 2 below, of 19-37 and critical deformation value range, within which the strain-induced martensite phase occurs, of 0.1-0.25. Formula 2:(see description), where Ni, Cu, Cr, N, Si and Mn indicate the overall content (wt%) of the respective constituent element, and K(x) is the distribution index of each constituent element (x) and is expressed by the formula 3 below, and V(gamma) is the constituent ratio of austenite (in the 0.45-0.75 range) Formula 3: K(x) = [amount of x element in ferrite phase] / [ amount of x element in austenite phase]

Owner:浦项股份有限公司

Method for producing a motor vehicle component and motor vehicle component

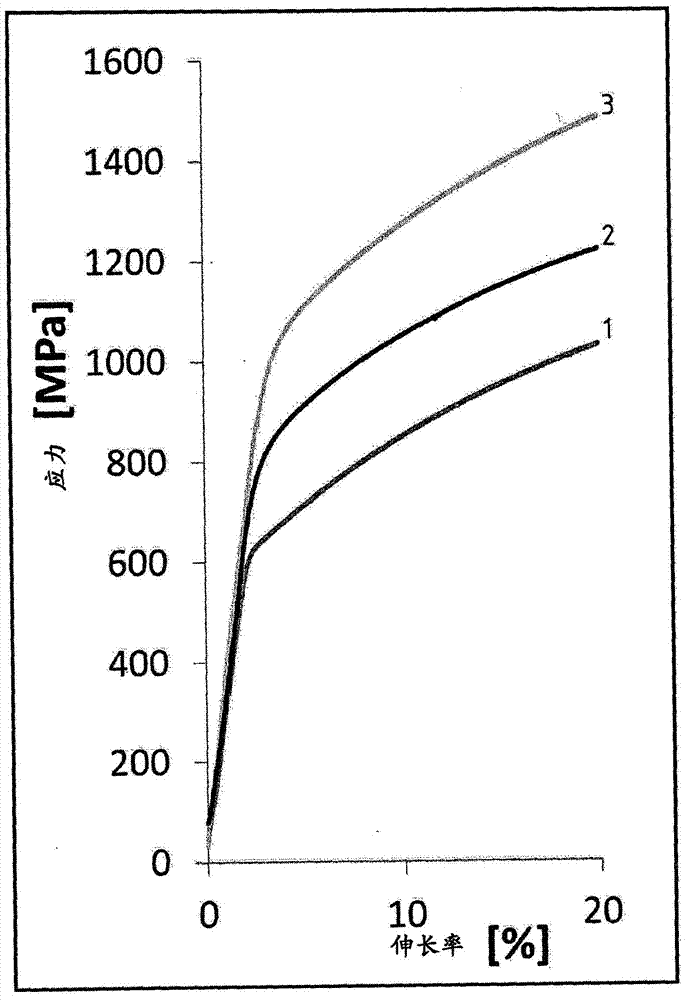

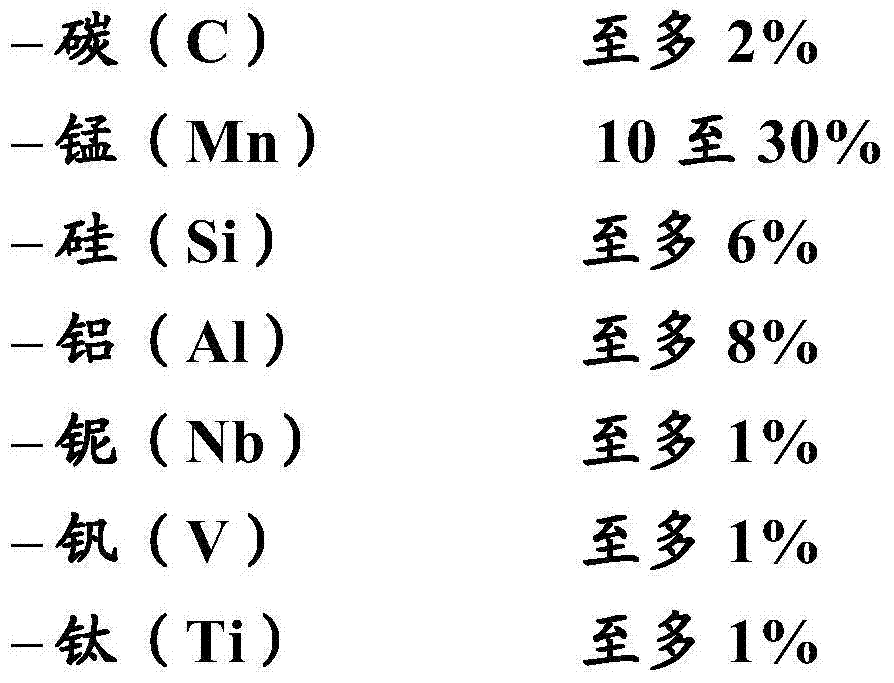

The present invention relates to a method for producing a motor vehicle component and the motor vehicle component. Particularly, in order to produce the motor vehicle component, steel plate slabs having 10 to 40 mJ / m2 stacking fault energy and 10 to 30% manganese are provided. At room temperature, the steel plate slab material can result in the formation of bicrystal at least partially having a major austenite texture. At + 30 DEG C and -250 DEG C temperature, the steel plate slab is at least partially subject to heat treatment and then cold forming. According to the method provided by the invention, yield point and tensile strength are substantially improved, and high ductility is also achieved.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

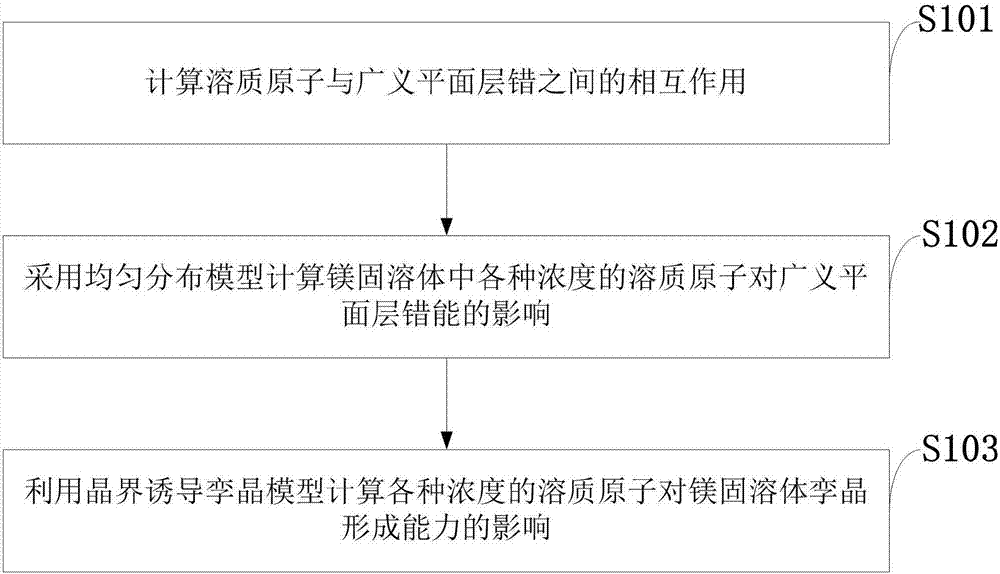

Method for computing twin-crystal forming ability of solid solution materials

InactiveCN107330215AImprove efficiencyLow costDesign optimisation/simulationSpecial data processing applicationsStacking faultFirst principle

The invention belongs to the technical field of twin-crystals, and discloses a method for computing the twin-crystal forming ability of solid solution materials. The method for computing the twin-crystal forming ability of the solid solution materials includes computing interaction between solute atoms and key point general plant stacking faults by the aid of first-principle theory periodic super-crystal cell processes when the solute atoms are doped in a plurality of adjacent layers of atoms; computing influence of the solute atoms with different levels of concentration in magnesium solid solution on general plane stacking fault energy by the aid of uniform distribution models; computing influence of the solute atoms with the different levels of concentration on the twin-crystal forming ability of the magnesium solid solution by the aid of crystal boundary induction twin-crystal models to obtain results which perfectly conform to experimental results. The method has the advantages that elements with the optimal influence on the twin-crystal forming ability of metal can be quickly and accurately found out, accordingly, the cost of experimental research can be saved, and theoretical guidance with significance on improving high-toughness alloy materials can be obtained.

Owner:HUNAN UNIV

Welding joint having remarkable impact resistance and abrasion resistance

InactiveUS20160271740A1High degreeWelding/cutting media/materialsSoldering mediaSlurryOil production

Provided is a welding joint having remarkable impact resistance and abrasion resistance. The welding joint having remarkable impact resistance and abrasion resistance comprises 0.02-0.75 wt % of C, 0.2-1.2 wt % of Si, 15-27 wt % of Mn, 2-7 wt % of Cr, 0.025 wt % or less of S, 0.025 wt % or less of P, 0.001-0.4 wt % of N, and the balance of Fe and other inevitable impurities, and having a stacking-fault energy of 15-40 mJ / m2 at 20° C. Further provided are a welding joint having remarkable low temperature impact toughness and abrasion resistance, and a welding joint very preferably applied to a slurry pipe and the like used in the oil sand industry field related to oil production.

Owner:POHANG IRON & STEEL CO LTD

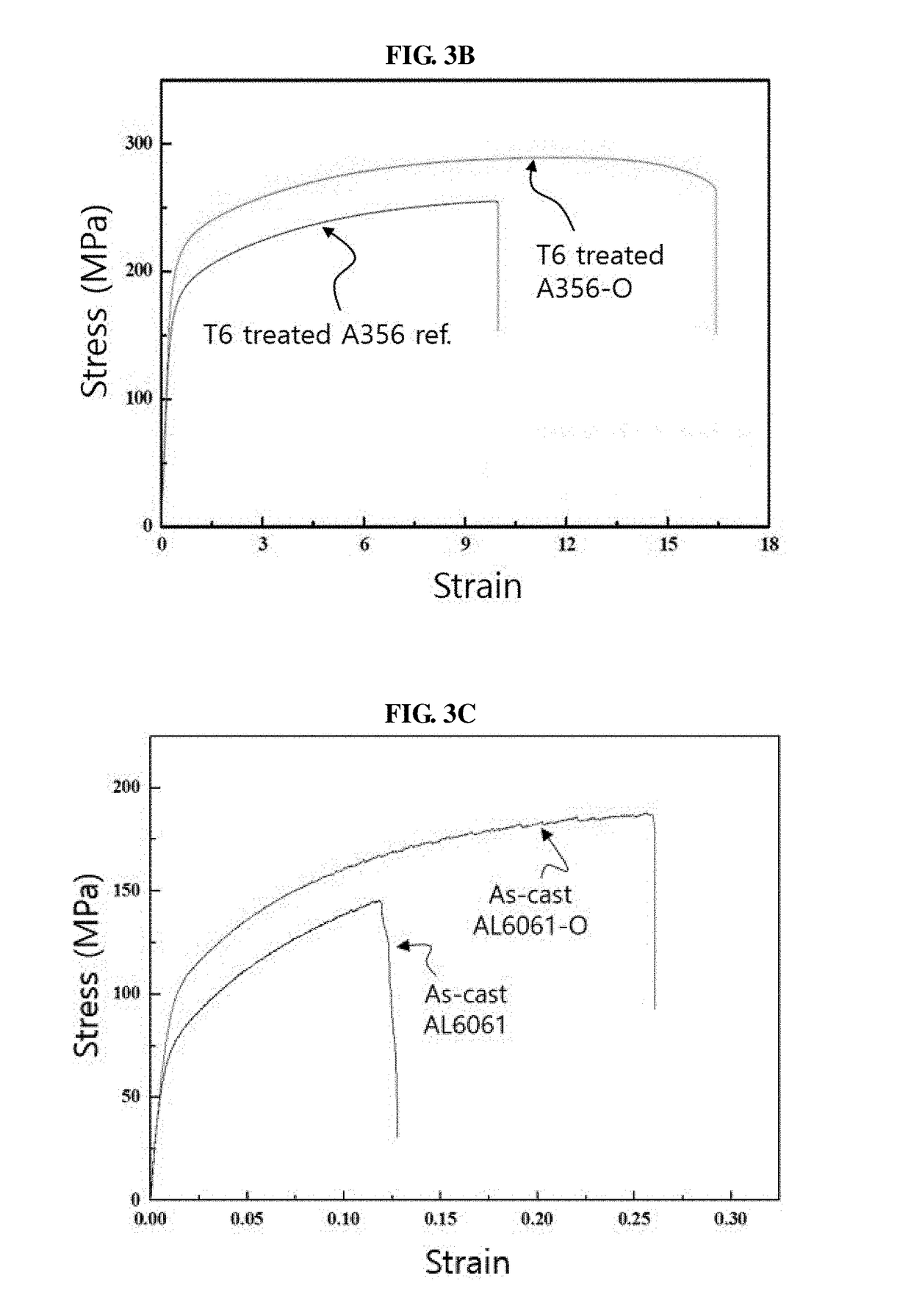

Engineered aluminum alloy and method of fabricating the same

InactiveUS20170240998A1High strengthHigh elongationTransportation and packagingMetal-working apparatusHigh intensityStacking-fault energy

Provided are an aluminum alloy having an adjusted microstructure in an aluminum matrix or an aluminum alloy matrix for high elongation percentage or high strength and a method of fabricating the same. The aluminum alloy includes an aluminum-based matrix; and a nonmetal element solidified in the aluminum-based matrix, wherein stacking fault energy of the aluminum alloy is decreased compared to that of pure aluminum.

Owner:IND ACADEMIC CORP FOUND YONSEI UNIV

Wear-resistant high-manganese steel based on TWIP effect and nano precipitation strengthening and preparation method and application of wear-resistant high-manganese steel

ActiveCN113941430AAvoid deformation and scrapReduce manufacturing costProcess efficiency improvementGrain treatmentsManganeseHigh wear resistance

The invention discloses wear-resistant high-manganese steel based on a TWIP effect and nano precipitation strengthening. The wear-resistant high-manganese steel comprises the following chemical element components in percentage by mass: 1.2%-1.6% of C, 18%-26% of Mn, 1.0%-2.0% of Mo, 0.3%-1.2% of V, 0.04%-0.08% of Nb, 0.3%-0.5% of Si, less than or equal to 0.003% of P, less than or equal to 0.005% of S and the balance of Fe and other inevitable impurities, wherein the microstructure of the wear-resistant high-manganese steel is austenite. The stacking fault energy is controlled within the range of 20-40 mJ / m<2>, so that a liner plate generates the TWIP effect, generates twin crystals and improves the wear resistance in the production and use process, the TRIP effect can be avoided, and strain-induced martensite cannot be generated, so that the surface of the liner plate is prevented from being deformed and scrapped, and the purposes of prolonging the service life and reducing the production cost of a mine are achieved.

Owner:TONGLING YOUSE JINSHEN WEAR RESISTANT MATERIAL

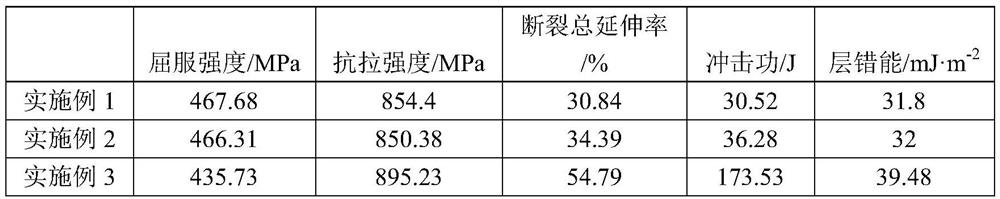

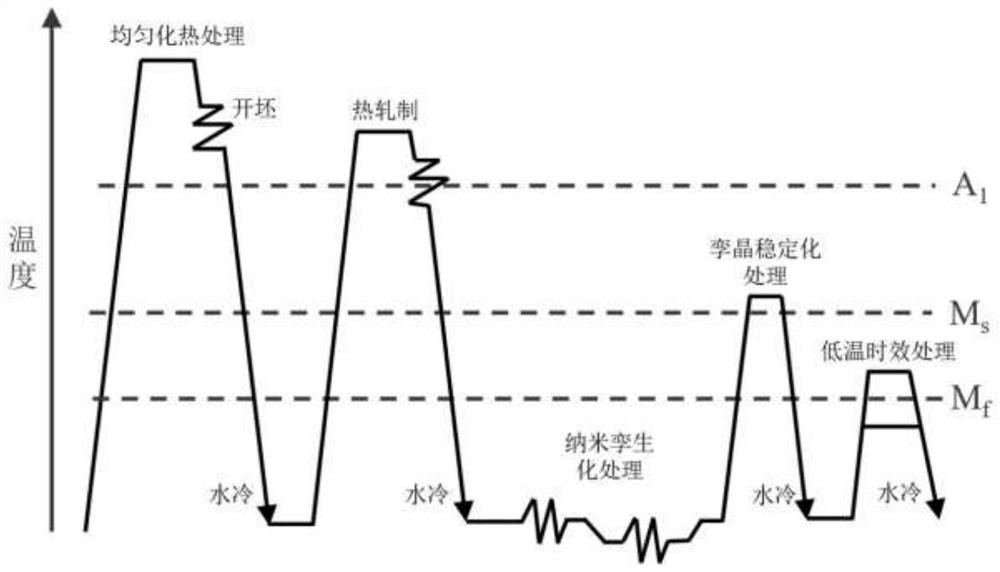

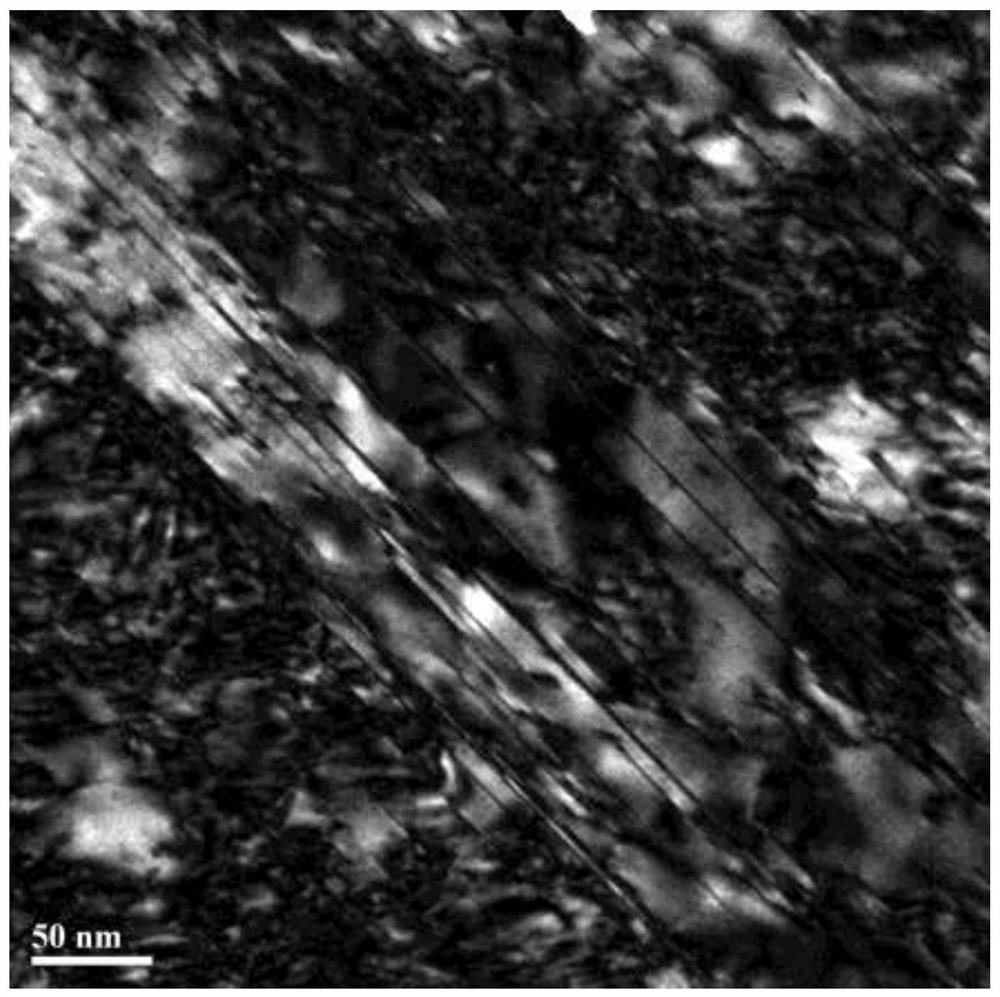

High-strength and high-toughness wear-resistant steel and preparation method for nano twin crystal reinforcement and toughening of high-strength and high-toughness wear-resistant steel

ActiveCN113388787AGood value for moneyImprove mechanical propertiesRoll force/gap control deviceTemperature control devicePressure castingIndustrial equipment

The invention relates to high-strength and high-toughness wear-resistant steel and a preparation method for nano twin crystal reinforcement and toughening of high-strength and high-toughness wear-resistant steel. The steel comprises the components in percent by mass: 0.35%-0.85% of C, 15.2%-24.8% of Mn, 0.1%-0.5% of Si, smaller than or equal to 1.0% of Al, smaller than or equal to 0.005% of S, smaller than or equal to 0.01% of P, 0.5%-1.5% of Nb, 0.2%-0.8% of Ti, 0.2%-0.75% of V, 0.005%-0.05% of N, 0.02%-0.1% of rare earth RE and the balance Fe and inevitable impurities. The stacking fault energy of an alloy is 24-30 kJ / m <2>, and the mass percent of the addition amount of Ti, Nb and V is 2: 1: 1. The preparation process comprises the steps of alloy smelting and negative pressure casting, homogenization heat treatment and cogging, hot rolling, nanometer twinning treatment, nanometer twinning stabilization and low-temperature aging treatment. According to the invention, fine structure regulation and control are carried out based on means of deformation and heat treatment by means of low fault energy and microalloying component optimization matching design, so that good structure matching is realized, and the alloy has high strength, high toughness and high wear resistance. The wear-resistant steel is excellent in comprehensive mechanical property, low in alloy cost, simple in preparation process, low in production and manufacturing cost and easy to put into industrial production and large-scale industrial equipment.

Owner:上交(徐州)新材料研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com