Wear-resistant high-manganese steel based on TWIP effect and nano precipitation strengthening and preparation method and application of wear-resistant high-manganese steel

A technology of precipitation strengthening and high manganese steel, which is applied to the improvement of process efficiency and grain processing, etc., can solve the problems of plastic deformation, volume expansion, workpiece deformation, etc., to enhance the yield strength and initial hardness, reduce production costs, improve durability The effect of grinding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

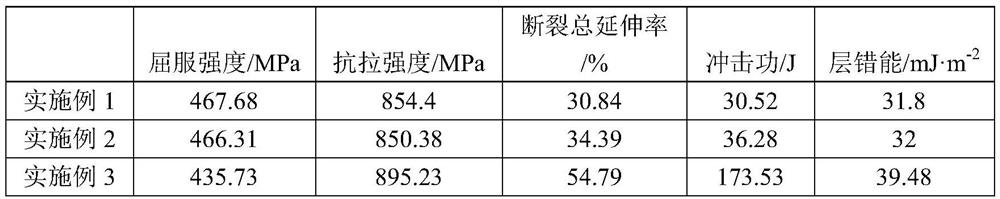

Embodiment 1

[0035] Based on TWIP effect and nano-precipitation strengthened wear-resistant high manganese steel, the high manganese steel material has the following chemical composition: C: 1.4%, Mn: 16.0%, Si: 0.4%, P: 2 .

[0036] The production process of the wear-resistant high manganese steel based on the TWIP effect and nano-precipitation strengthening includes the following steps:

[0037] (1) Smelting and refining: Use induction furnace or electric arc furnace with basic lining for smelting, first add steel scrap and high-carbon ferromanganese, and then add ferromolybdenum, medium-carbon ferromanganese, low-carbon ferromanganese, and micro-carbon ferromanganese in turn after melting , metal manganese and ferrovanadium are completely melted, and the composition is adjusted until the mass percentage requirement of the chemical composition of the high manganese steel is met, the temperature is raised to 1650° C., and the heat preservation is carried out for 5 minutes. The high mangane...

Embodiment 2

[0043] Wear-resistant high manganese steel based on TWIP effect and nano-precipitation strengthening, the high manganese steel material has the following chemical composition: C: 1.5%, Mn: 18.0%, Si: 0.5%, P: 0.0025%, S: 0.004% , Mo: 1.2%, V: 0.8%, Nb: 0.04%, the balance is Fe, and the stacking fault energy is 32.00mJ / m 2 .

[0044] The production process of the wear-resistant high manganese steel based on the TWIP effect and nano-precipitation strengthening includes the following steps:

[0045] (1) Smelting and refining: Use induction furnace or electric arc furnace with basic lining for smelting, first add steel scrap and high-carbon ferromanganese, and then add ferromolybdenum, medium-carbon ferromanganese, low-carbon ferromanganese, and micro-carbon ferromanganese in turn after melting , metal manganese and ferrovanadium are completely melted, and the composition is adjusted until the mass percentage requirement of the chemical composition of the high manganese steel is ...

Embodiment 3

[0051] Wear-resistant high manganese steel based on TWIP effect and nano-precipitation strengthening, the high manganese steel material has the following chemical composition: C: 1.2%, Mn: 26.0%, Si: 0.3%, P: 0.003%, S: 0.005% , Mo: 2.0%, V: 1.2%, Nb: 0.08%, the balance is Fe, and the stacking fault energy is 39.48mJ / m 2 .

[0052] The preparation process is the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com