Austenitic high mn stainless steel excellent in workability

A stainless steel technology with excellent processability, applied in the field of austenitic high Mn stainless steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] Stainless steel having the chemical composition shown in Table 1 was smelted and hot-rolled at a heating temperature of 1200° C. to produce a hot-rolled steel sheet with a thickness of 4.0 mm. The hot-rolled steel sheet is annealed at 1120°C with a soaking time of 2 minutes, cold-rolled to a plate thickness of 1.5 mm after pickling, and then intermediate annealed at 1060°C with a soaking time of 2 minutes. After pickling, the plate thickness is 0.7 mm. mm of cold-rolled steel sheet, and perform final annealing (annealing pickling material) at 1060°C and soaking time for 1 minute. A 60% cold rolled material was obtained by cold rolling the intermediate annealed pickled material to 0.6 mm.

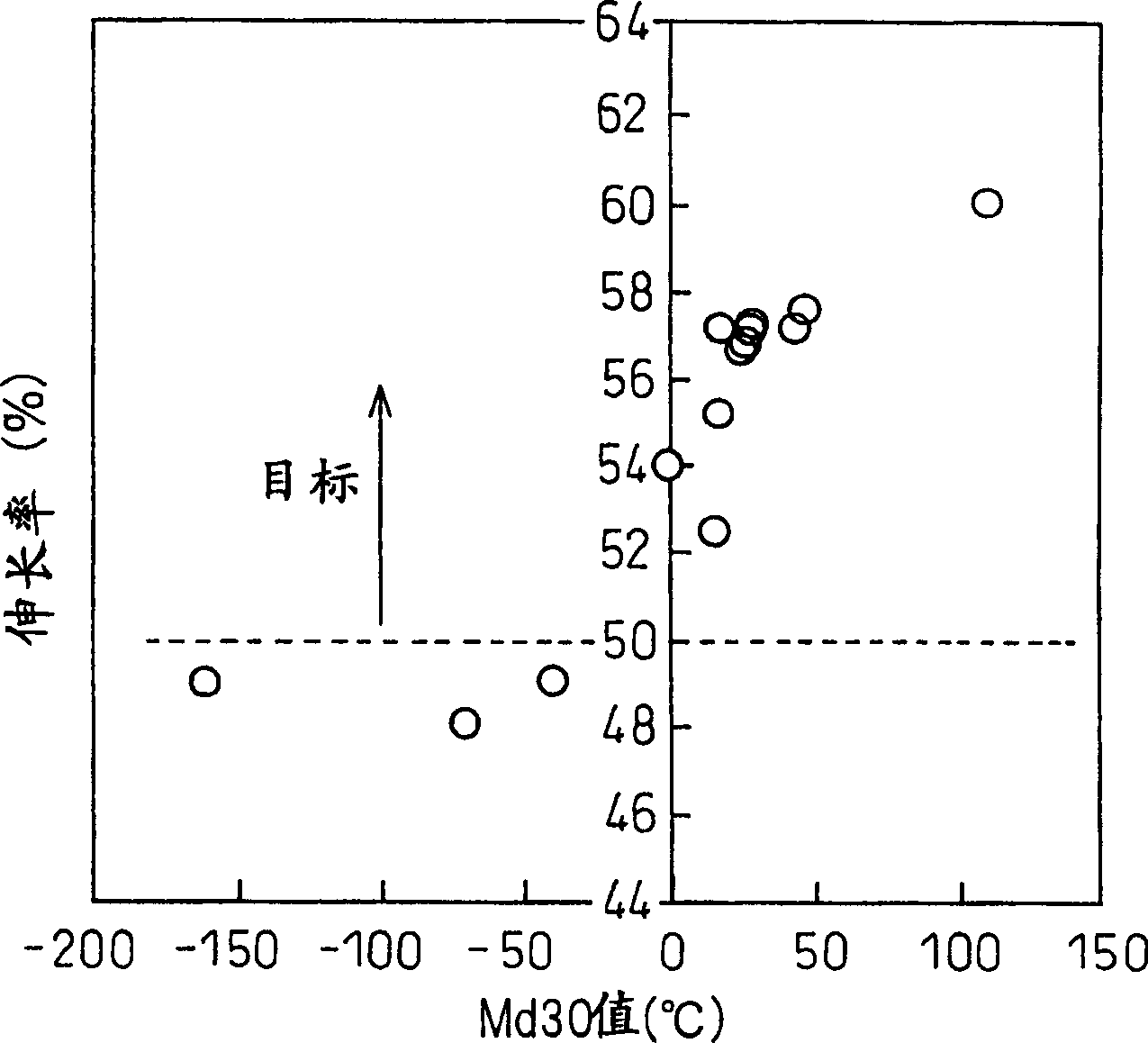

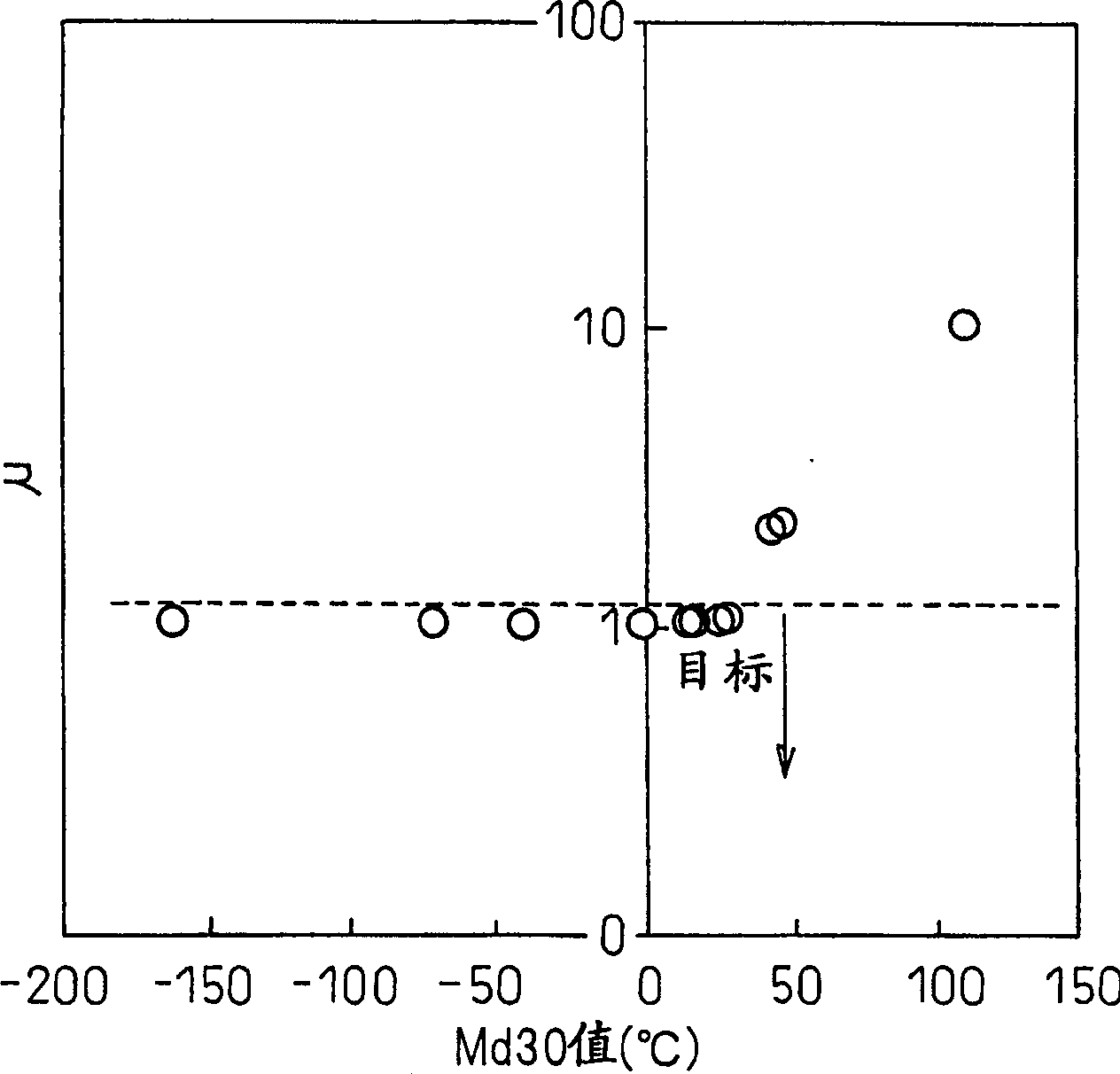

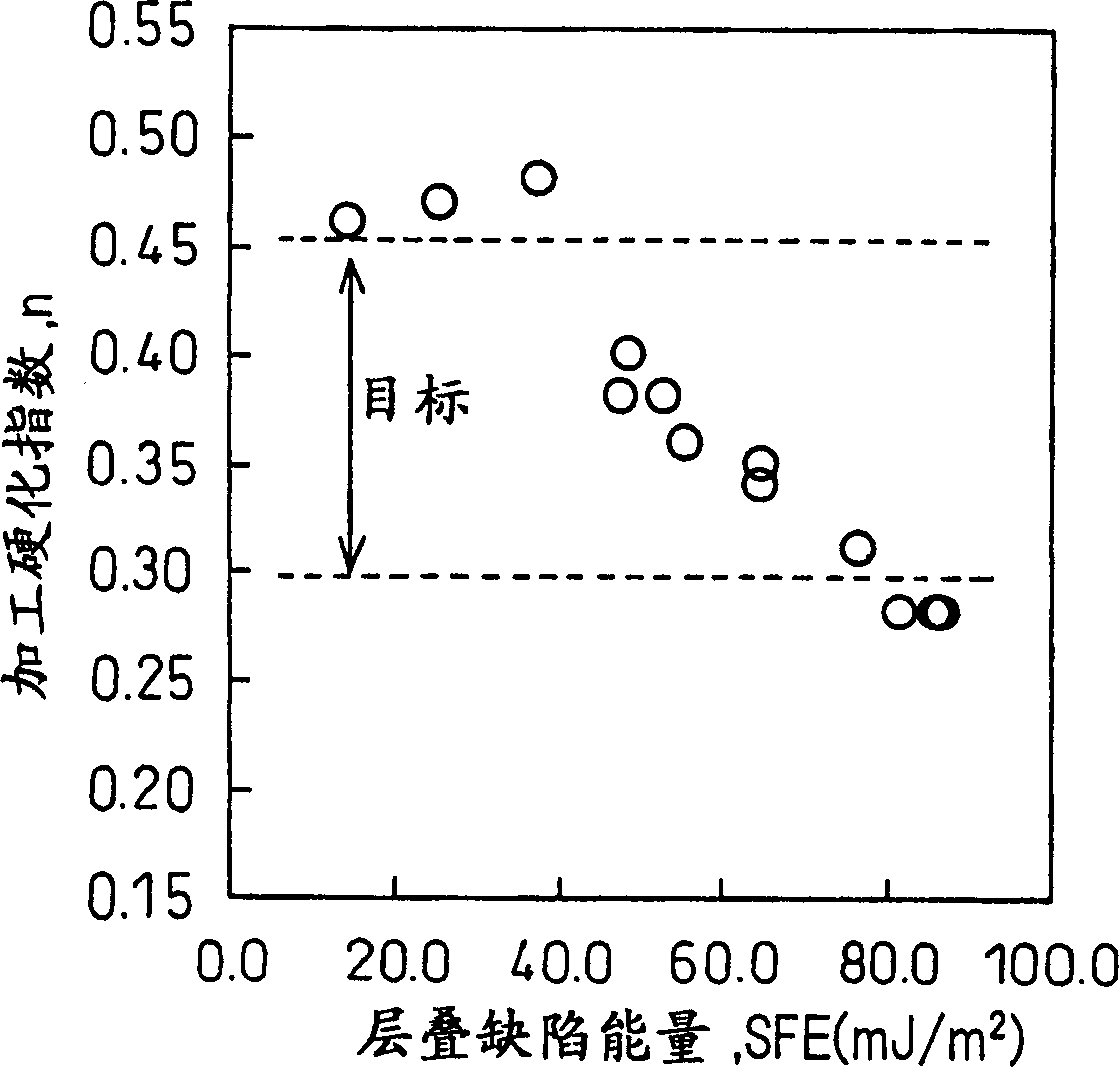

[0048] Cut the JIS13B tensile test piece from the annealed and pickled material, and measure the 0.2% endurance, tensile strength, elongation, and work hardening index n by tensile test. The work hardening exponent n is to obtain the actual strain ε corresponding to 25% and 35% of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com