High-entropy alloy and preparation method thereof

A high-entropy alloy and alloy technology, applied in the field of metal materials, can solve problems such as the reduction of the overall plasticity of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034]The present invention also provides a method for preparing the high-entropy alloy described in the above technical solution, comprising the following steps:

[0035] (1) Smelting metal raw materials to obtain smelting liquid alloy water;

[0036] (2) casting the smelted liquid alloy water obtained in the step (1) into an ingot, hot forging and hot rolling in sequence to obtain an alloy precursor;

[0037] (3) The alloy precursor obtained in the step (2) is sequentially subjected to solid solution, cold rolling and calcining to obtain a high-entropy alloy.

[0038] The invention smelts metal raw materials to obtain smelting liquid alloy water. In the present invention, the smelting temperature is preferably 1700-1900°C, more preferably 1750-1850°C, most preferably 1780-1820°C. In the present invention, the smelting time is preferably 15-20 minutes, more preferably 16-19 minutes, and most preferably 17-18 minutes. In the present invention, the smelting atmosphere is pre...

Embodiment 1

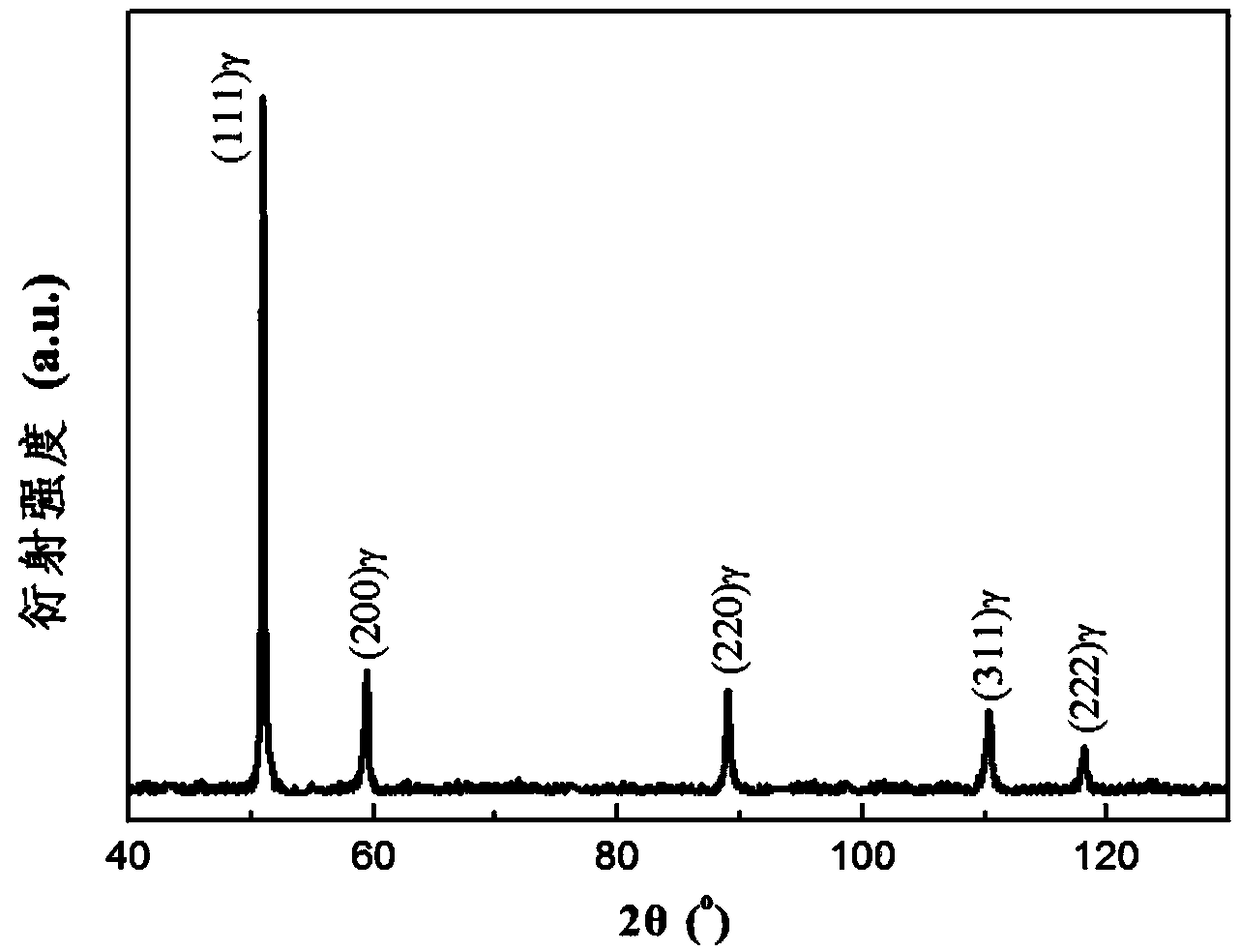

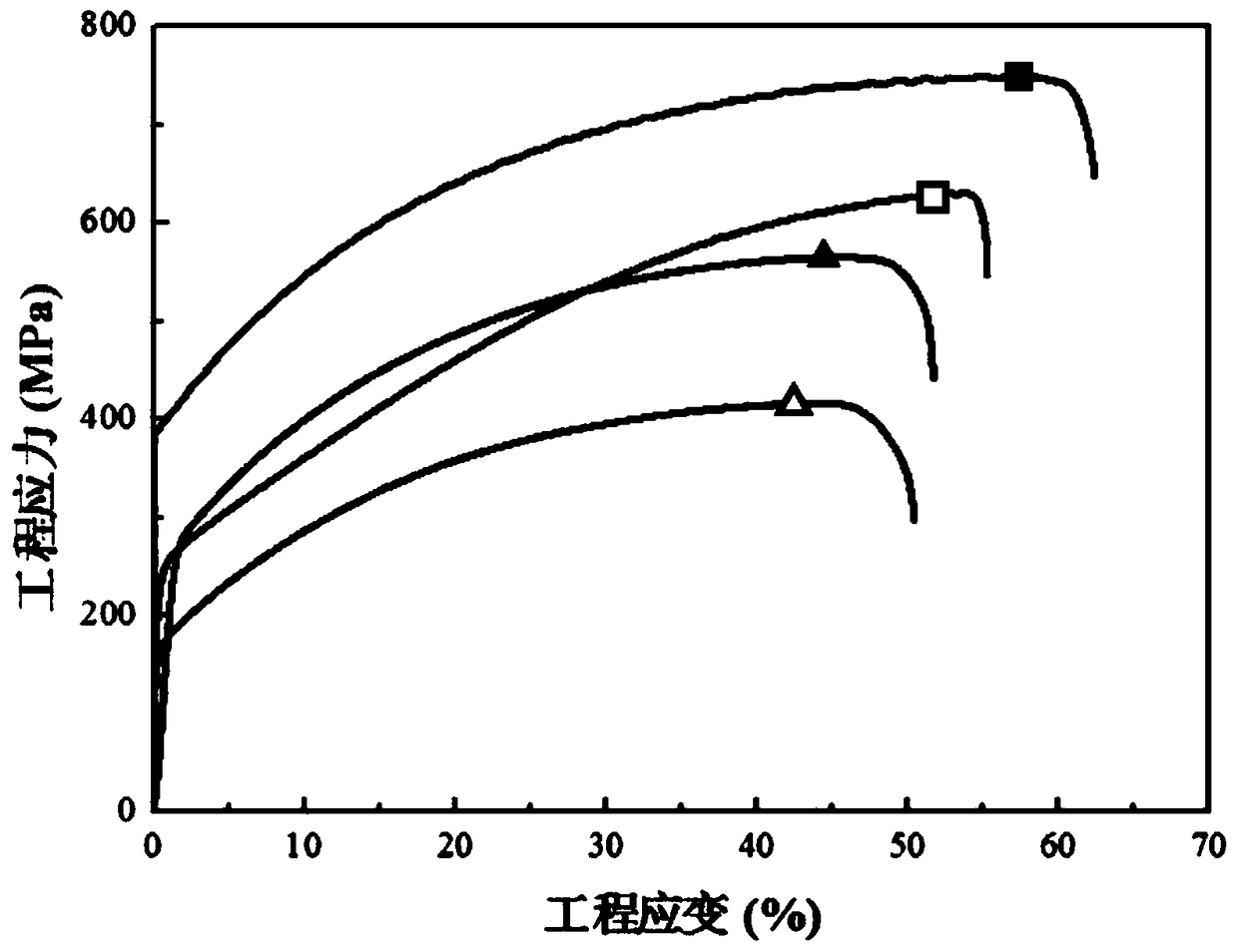

[0050] A high-entropy alloy prepared from the following elements in atomic percent: 40.0% Fe, 10.0% Co, 40.0% Mn and 10.0% Cr.

[0051] The preparation method of above-mentioned high-entropy alloy comprises the following steps:

[0052] (1) Smelting the above-mentioned metal raw materials in a vacuum induction furnace at 1800°C for 5 times to obtain smelting liquid alloy water;

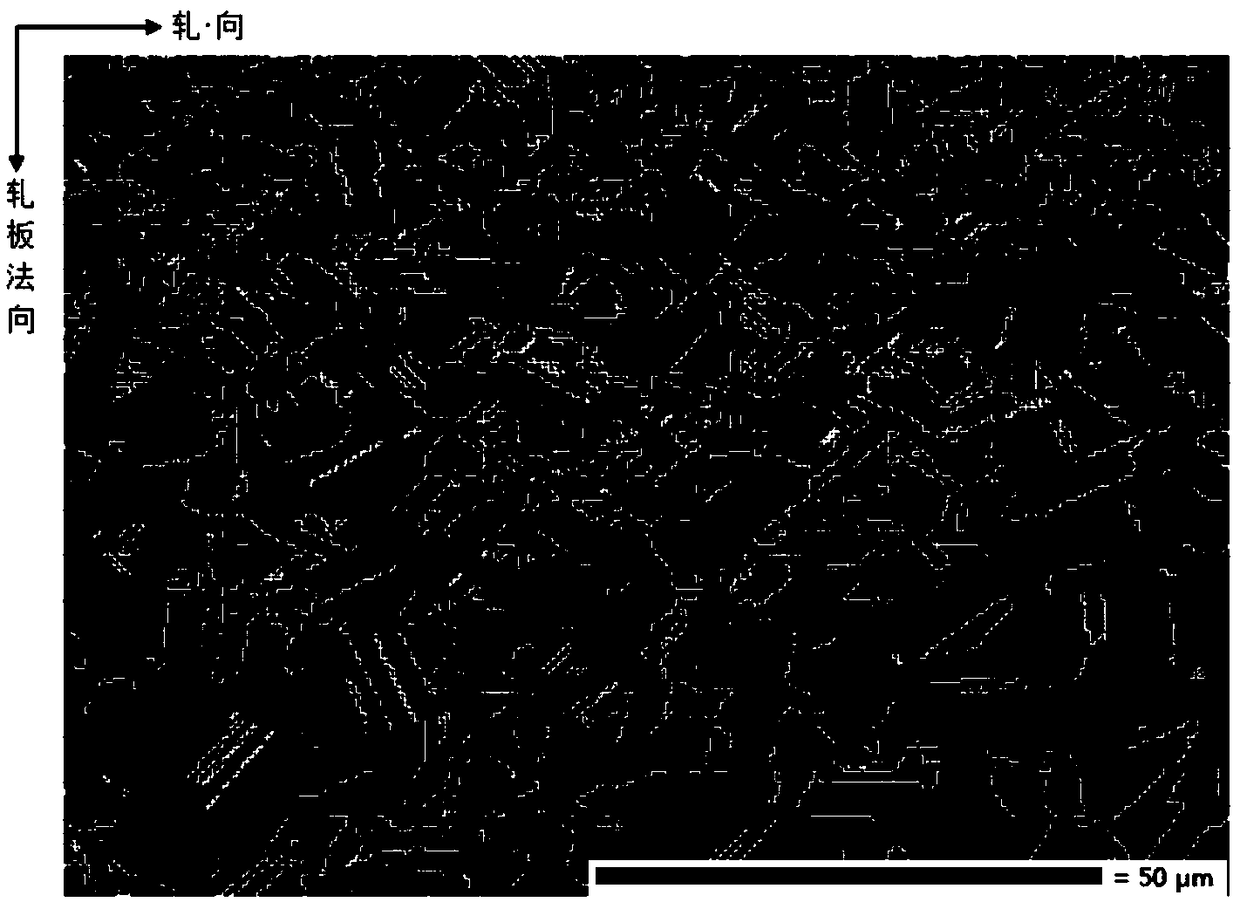

[0053] (2) The smelted liquid alloy water obtained in the step (1) is sequentially cast into cylindrical ingots, and the cylindrical ingots are hot-calcined at 1200° C. for 10 minutes, so that the cylindrical ingots become square in cross section (80×80mm 2 ) of a rectangular parallelepiped ingot, and then the rectangular parallelepiped ingot is hot-rolled at 900° C., and the relative pressing force of the hot rolling is 50%, to obtain an alloy precursor whose plate thickness is 40 mm;

[0054] (3) The alloy precursor obtained in the step (2) is solid-dissolved at 1200° C. for 2 hours, and cooled to...

Embodiment 2

[0063] A high-entropy alloy prepared from the following elements in atomic percent: 40.0% Fe, 10.0% Co, 40.0% Mn and 10.0% Cr.

[0064] The preparation method of above-mentioned high-entropy alloy comprises the following steps:

[0065] (1) Smelting the above-mentioned metal raw materials in a vacuum induction furnace at 1800°C for 5 times to obtain smelting liquid alloy water;

[0066] (2) The smelted liquid alloy water obtained in the step (1) is successively cast into cylindrical ingots, and the cylindrical ingots are hot-calcined at 1200° C. for 10 min, so that the cross-section of the cylindrical ingots becomes square ( 80×80mm 2 ) of a rectangular parallelepiped ingot, and then hot rolling the rectangular parallelepiped ingot at 900° C., the relative pressing force of the hot rolling is 50%, to obtain an alloy precursor whose plate thickness is 40 mm;

[0067] (3) The alloy precursor obtained in the step (2) is solid-dissolved at 1200° C. for 2 hours, cooled to room te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com