Preparation method for twinning induced plasticity (TWIP) steel for low-cost large-expansibility expansion pipe and steel pipe

An expansion rate, low-cost technology, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems that cannot meet the expansion tube technology, the expansion force increases, and it is difficult to meet the requirements, so as to improve the fluidity and wettability and the existing form of impurities, improving the cleanliness and improving the effect of anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

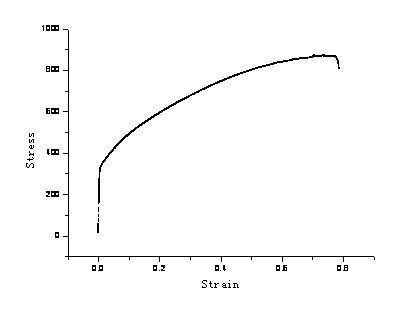

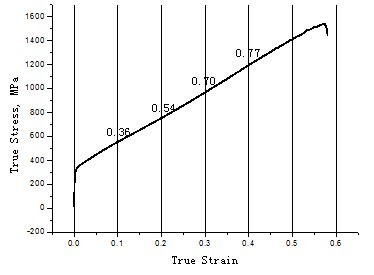

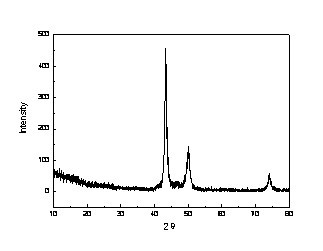

[0039] The chemical composition of TWIP steel for expansion pipe with large expansion rate is: C content 0.32%, Mn content 18.84%, Cr content 0.87%, Al content 0.016%, Si content 0.53%, Re content 0.032%, The P content is 0.0039%, the S content is 0.0018%, and the rest is iron.

[0040] The steel is smelted in an electric furnace, deoxidized by rare earth aluminum-iron alloys, tapped at 1500-1600°C, cast at 1450-1550°C, hot-extruded at 1250-1100°C after blanking, or rolled into seamless steel pipes at 1250-850°C After the steel pipe is air-cooled, or hot-rolled or cold-rolled into a steel plate of a certain thickness, it is made into a welded pipe through high-frequency straight seam welding technology, and finally quenched and water-cooled at 950-1050°C to make an expandable sleeve of a certain specification. The mechanical performance test results are: tensile strength R m : 968.4MPa, yield strength R P0.2 : 316MPa, elongation after fracture A: 59.5%, strong plastic produc...

Embodiment 2

[0046] TWIP steel for expansion pipe with large expansion rate, its chemical composition is as follows: C content 0.45%, Mn content 20.06%, Cr content 0.74%, Al content 0.018%, Si content 0.63%, Re content 0.033%, P content 0.0045%, the S content is 0.0019%, and the rest is iron.

[0047] The steel is smelted in an electric furnace, deoxidized by rare earth aluminum-iron alloys, tapped at 1500-1600°C, cast at 1450-1550°C, hot-extruded at 1250-1150°C after blanking, and finally quenched and water-cooled at 950-1050°C to make a certain specifications of the expandable sleeve. The mechanical performance test results are: tensile strength R m : 878MPa, yield strength R P0.2 : 325MPa, elongation after fracture A: 66.58%, strong plastic product k: 58457MPa%.

Embodiment 3

[0049] TWIP steel for expansion pipe with large expansion rate, its chemical composition is as follows: C content 0.335%, Mn content 19.44%, Cr content 0.42%, Al content 0.015%, Si content 0.69%, Re content 0.031%, P The iron content is 0.0049%, the S content is 0.0018%, and the rest is iron.

[0050]The steel is smelted in an electric furnace, deoxidized by rare earth aluminum-iron alloys, tapped at 1500-1600°C, cast at 1450-1550°C, hot-extruded at 1250-1150°C after billeting, or rolled into seamless steel pipes at 1250-850°C After the steel pipe is air-cooled, or hot-rolled, cold-rolled into a certain thickness of the steel plate and then made into a welded pipe through high-frequency straight seam welding technology, and finally quenched and water-cooled at 950-1050 ° C to make a certain specification of expandable sleeve. The mechanical performance test results are: tensile strength R m : 1065.6MPa, yield strength R P0.2 : 535MPa, elongation after fracture A: 67%, strong...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com