Component optimization design method of austenite Fe-Mn-Al-C light alloy steel

A fe-mn-al-c, optimized design technology, applied in the field of metal materials, can solve the problem of micro solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

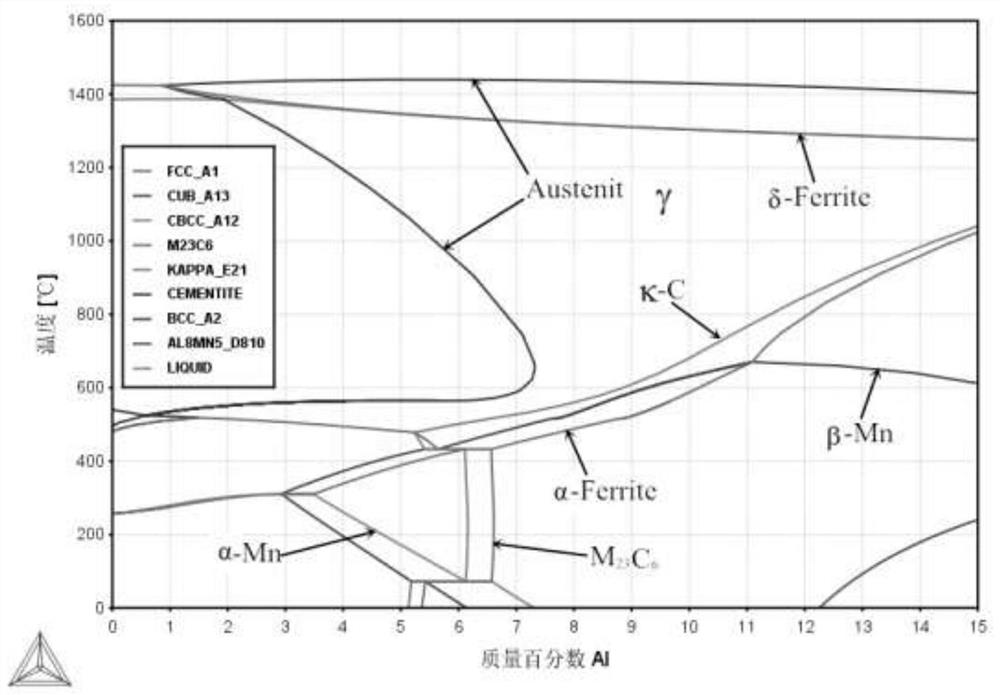

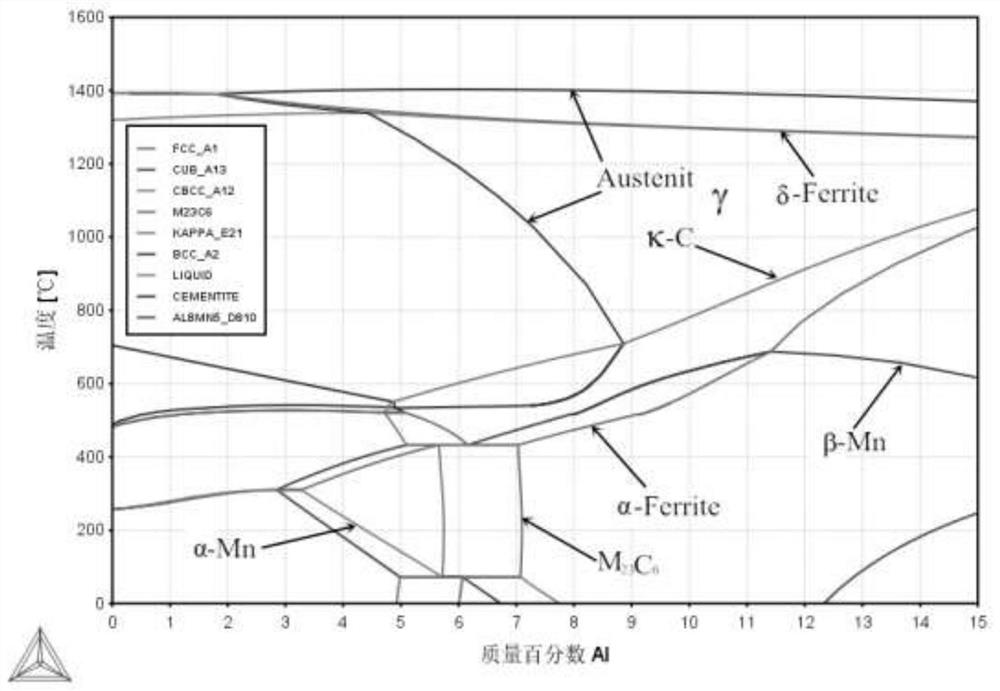

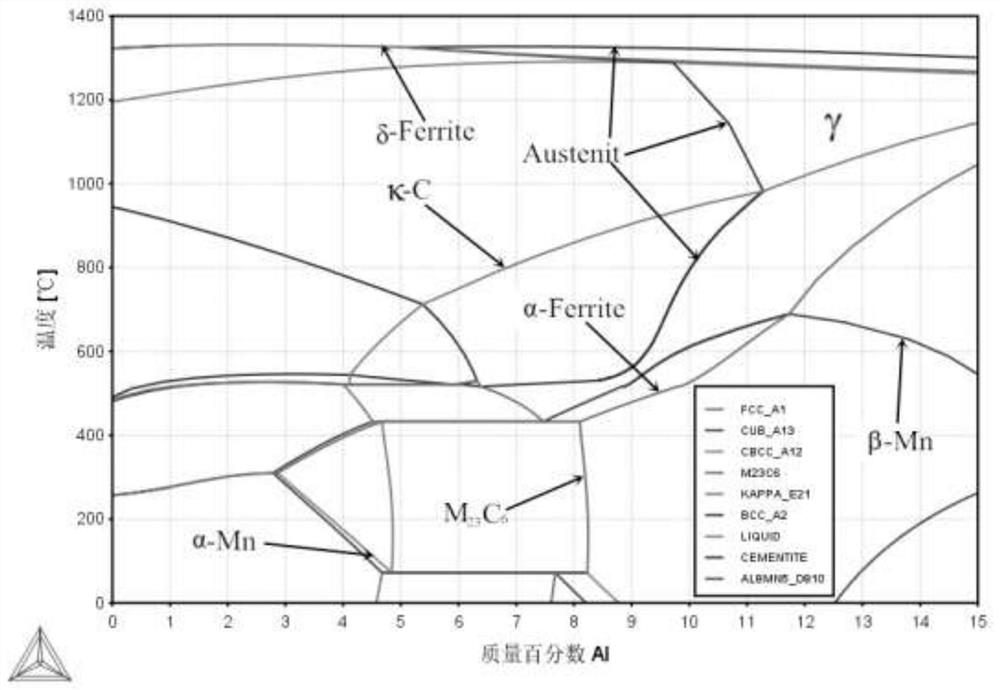

[0043] Fe-Mn-Al-C alloy components of an austenitic light optimization method, comprising the steps of:

[0044] S1: the development of typical chemical composition

[0045] In the chemical composition range of the austenitic Fe-Mn-Al-C alloy light based on defined, as shown in Table 1, to develop a Mn content corresponding to a respective different contents of Al, C typically steel chemical composition;

[0046] For the range of austenitic Fe-Mn-Al-C alloy element light component initially calculated as: Mn: 20-30wt%, Al: 5-12wt%, C: 0.5-1.5wt%, the balance being Fe, in a typical chemical composition of the Al alloy elements α stabilizing element, in a typical chemical composition of the alloy elements Mn is an austenite stabilizing element γ, in a typical chemical composition of alloy elements of C strong carbide forming element for promoting formation of single-phase γ austenite phase;

[0047] Table 1 Typical austenitic Fe-Mn-Al-C alloy chemical composition and the light value...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com