High-strength and high-ductility steel sheet and method of manufacturing the same

a high-ductility, steel sheet technology, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of difficult to achieve an elongation of 30% or more, short elongation, and high work hardening of steel sheets, so as to achieve high work hardening, reduce manufacturing costs, and effectively control the effect of racking fault energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

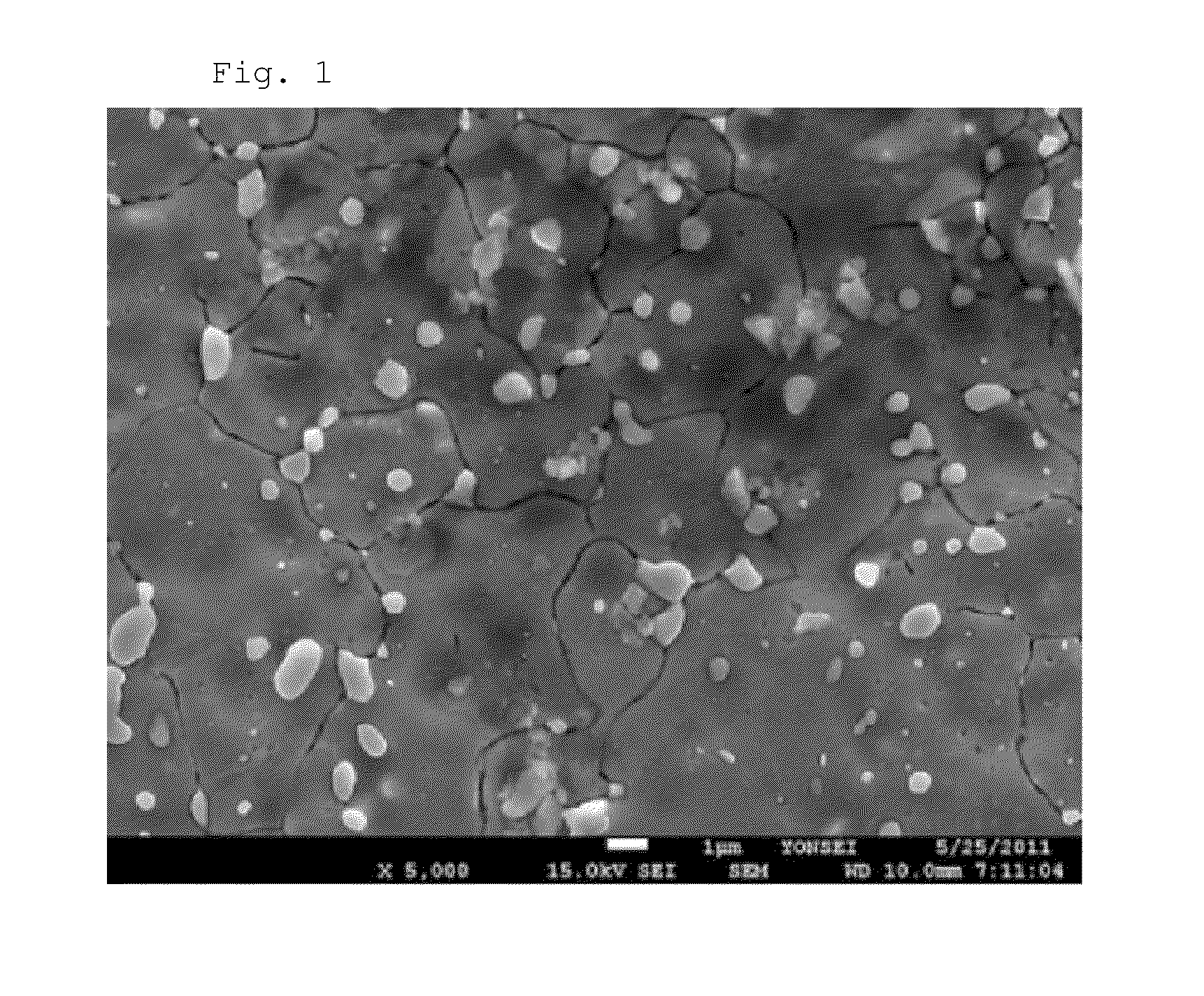

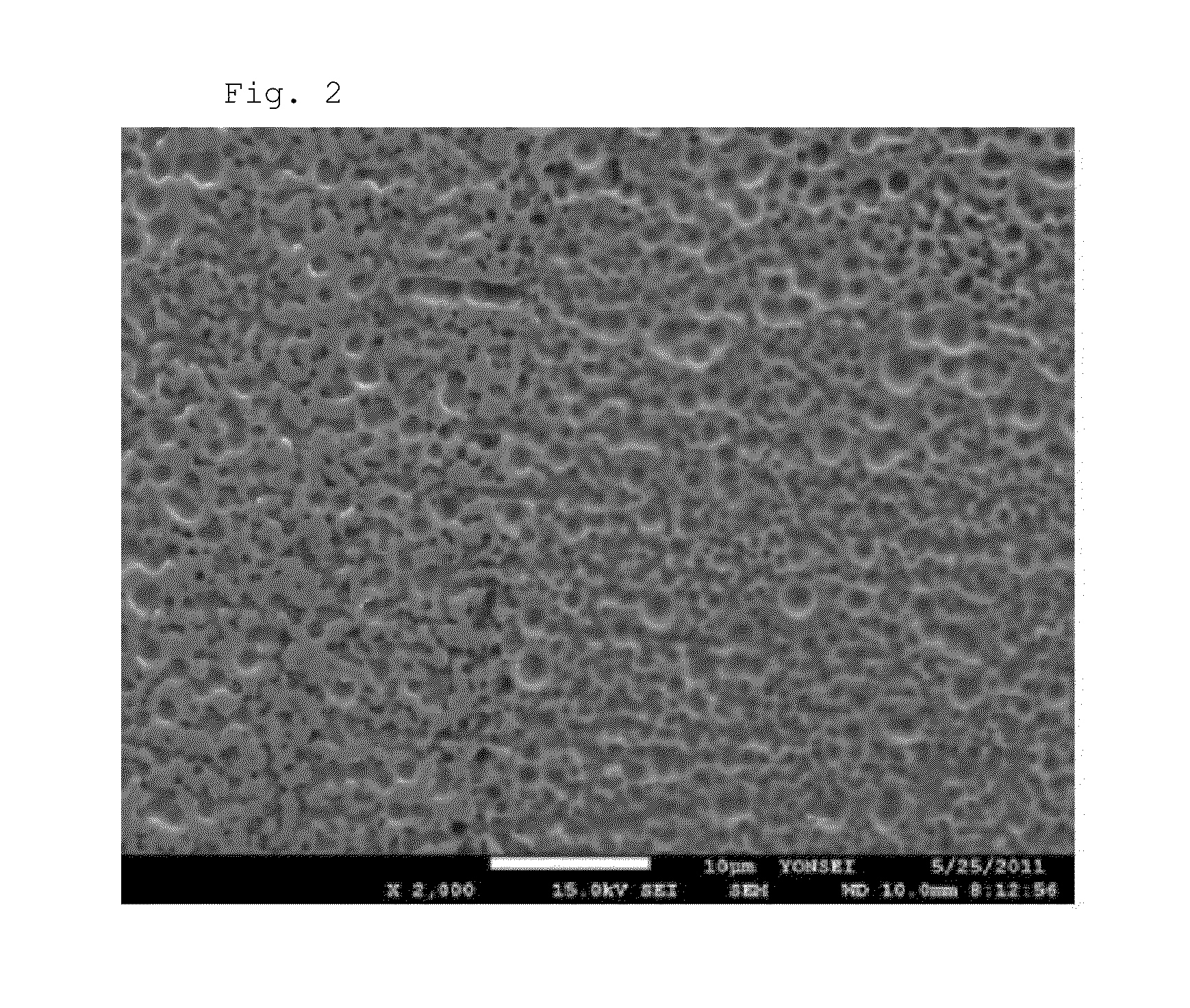

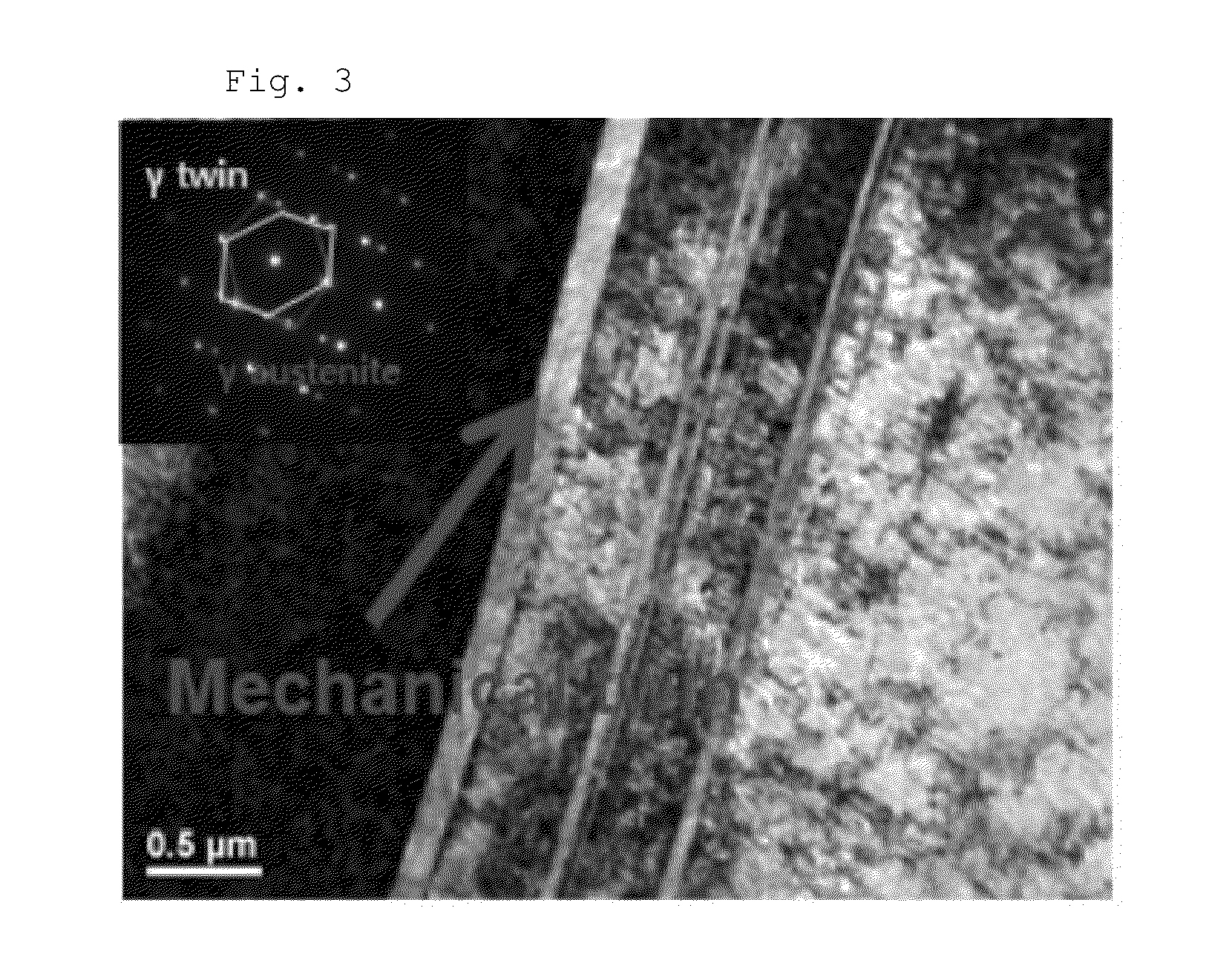

[0055]3 mm thick steel sheets, the chemical compositions of which are presented in Table 1 below, were formed by heating at a temperature of 1100° C. or higher, followed by hot rolling at a temperature of 900° C. or higher. The steel sheets were subsequently subjected to oil cooling or water cooling, thereby manufacturing steel samples (Inventive Examples 1 to 3 and Comparative Examples 1 to 7). In addition, part of the hot-rolled steel samples were subjected to annealing heat treatment at 800 to 1200° C. for 5 to 10 minutes, followed by oil cooling or water cooling.

TABLE 1Composition (wt %)Sample No.CMnCrRemarksInventive Ex. 11.227.343.03Water cooled afterannealed at 1200° C.Inventive Ex. 21.187.234.89Water cooled afterannealed at 1200° C.Inventive Ex. 31.237.426.92Water cooled afterannealed at 1200° C.Comp. Ex. 11.227.343.03Water cooled afterannealed at 1000° C.Comp. Ex. 21.187.244.89Water cooled afterannealed at 1000° C.Comp. Ex. 31.237.426.92Water cooled afterannealed at 1000° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com