High manganese nitrogen-containing steel sheet having high strength and high ductility, and method for manufacturing the same

a high ductility, high manganese nitrogen technology, applied in the direction of furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of difficult to guarantee an elongation of 30% or more, steel sheets with significantly low ductility, and excessive low elongation, etc., to achieve high tensile strength, high degree of work hardening, and effective regulation of stacking fault energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

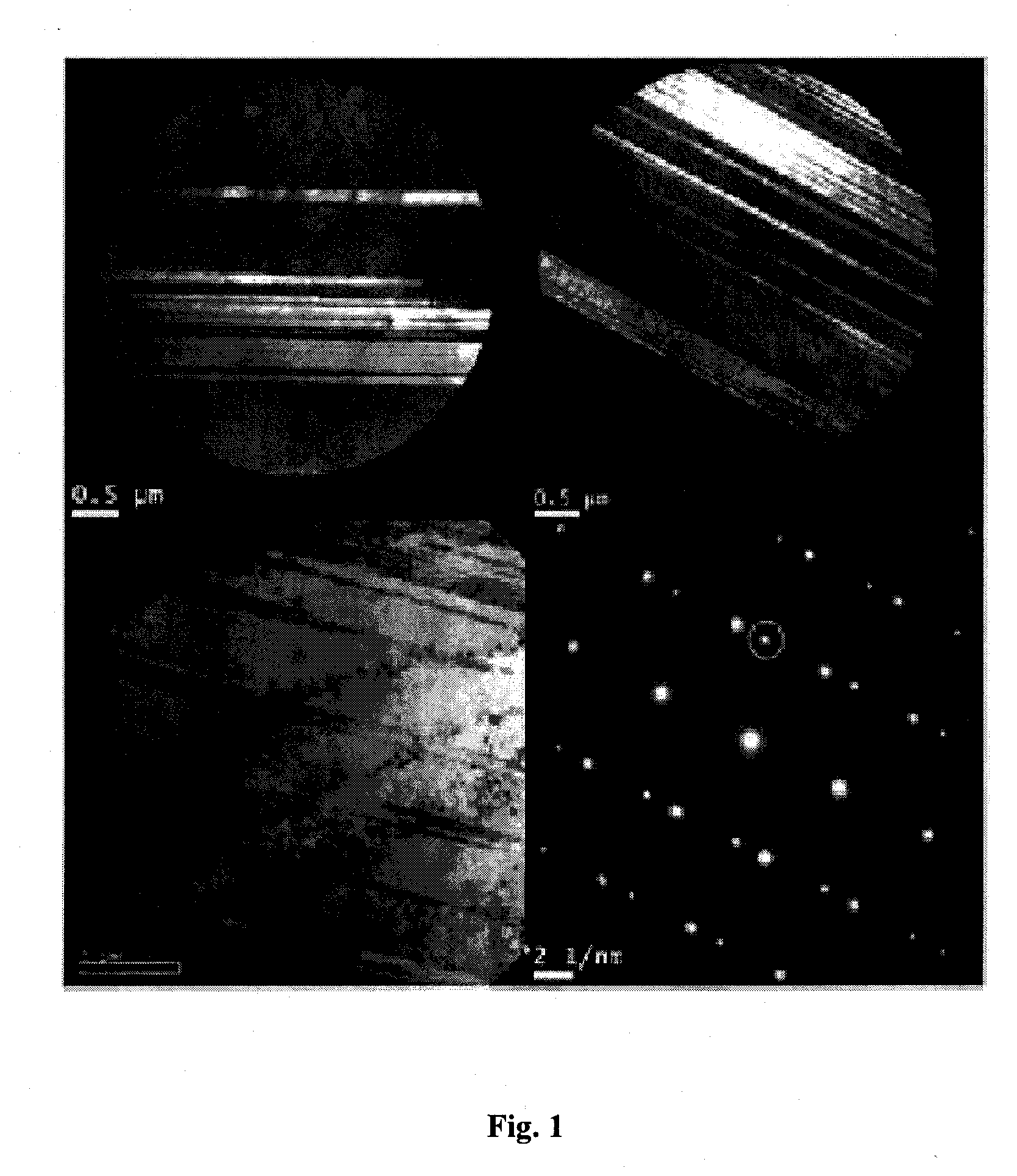

[0037]Exemplary embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

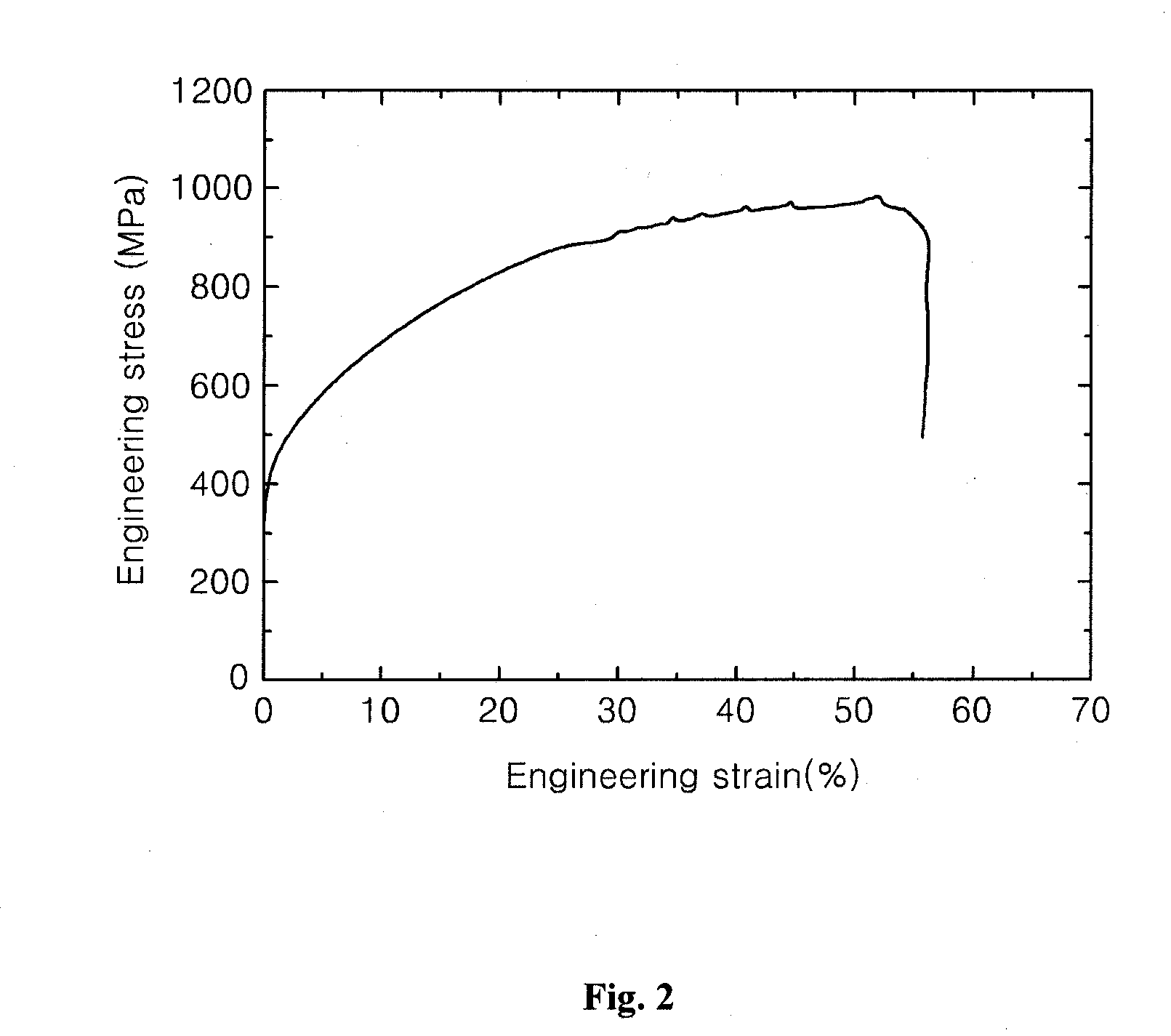

[0038]In high manganese-nitrogen containing steel sheets according to exemplary embodiments, carbon and nitrogen are added while lowering the manganese content to be in the range of 10˜20 wt % to have a single austenite phase structure at room temperature, as compared with conventional twin induced plasticity (TWIP) steel containing 20 wt % of manganese. Particularly, nitrogen induces not only solid solution strengthening effects, but also mechanical twins by affecting the stacking fault energy.

[0039]Thus, the high manganese-nitrogen containing steel sheets according to the exemplary embodiments include the aforementioned alloy elements, thereby achieving an elongation of 50% or more and higher yield strength and tensile strength than conventional TWIP steel while reducing the amounts of expensive alloy elements such as manganese or aluminum below those of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wt % | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com