TWIP steel and preparation method thereof

A technology of induced plasticity and twinning, which is applied in the field of alloy preparation, can solve problems such as difficulty in obtaining higher strength and higher plasticity, and achieve the effect of promoting the TWIP effect, broad application prospects, and increasing stacking fault energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0035] A preferred embodiment of the present invention is:

[0036] (1) Preparation of master alloy: use Fe, Mn, Cu, Al, Ni and C high-purity metals or powders with a purity of ≥99.9wt%, and use suction casting after high-vacuum arc melting or melting metal molds in vacuum induction furnaces Prepare TWIP steel by casting or similar smelting methods;

[0037] (2) Hot rolling, cold rolling and solution treatment: the TWIP steel obtained in step (1) is hot-rolled at 1100-1200°C, and then cold-rolled at 65-75% of the pass reduction, and then rolled at 1000 Solution treatment is carried out at ~1200°C for 1.5~3h.

[0038](3) Strong magnetic field aging treatment: place the sample obtained in step (2) in a strong magnetic field of 1-10T, adjust the position of the sample, keep it warm for 2-4 hours at a temperature of 525-575° C., and then quench to obtain TWIP steel.

Embodiment 1

[0040] (1) Master alloy preparation: use high-purity metals or powders such as Fe, Mn, Cu, Al, Ni and C with a purity ≥ 99.9 wt%, and smelt the metals in a vacuum induction furnace. During the smelting process, 1.5Hz low-frequency electromagnetic stirring is applied, and the alloy ingot is prepared by casting in a copper mold under the protection of 0.1 standard atmospheric pressure argon;

[0041] (2) Hot rolling, cold rolling and solution treatment: the TWIP steel obtained in step (1) is subjected to hot rolling treatment at 1100°C, and then after the cold rolling treatment with a pass reduction of 65%, it is solidified at 1000°C. Dissolve for 1.5h.

[0042] (3) Strong magnetic field aging treatment: place the sample obtained in step (2) in a 0.1T strong magnetic field, adjust the position of the sample, keep it at 525° C. for 2 hours and then quench to obtain TWIP steel.

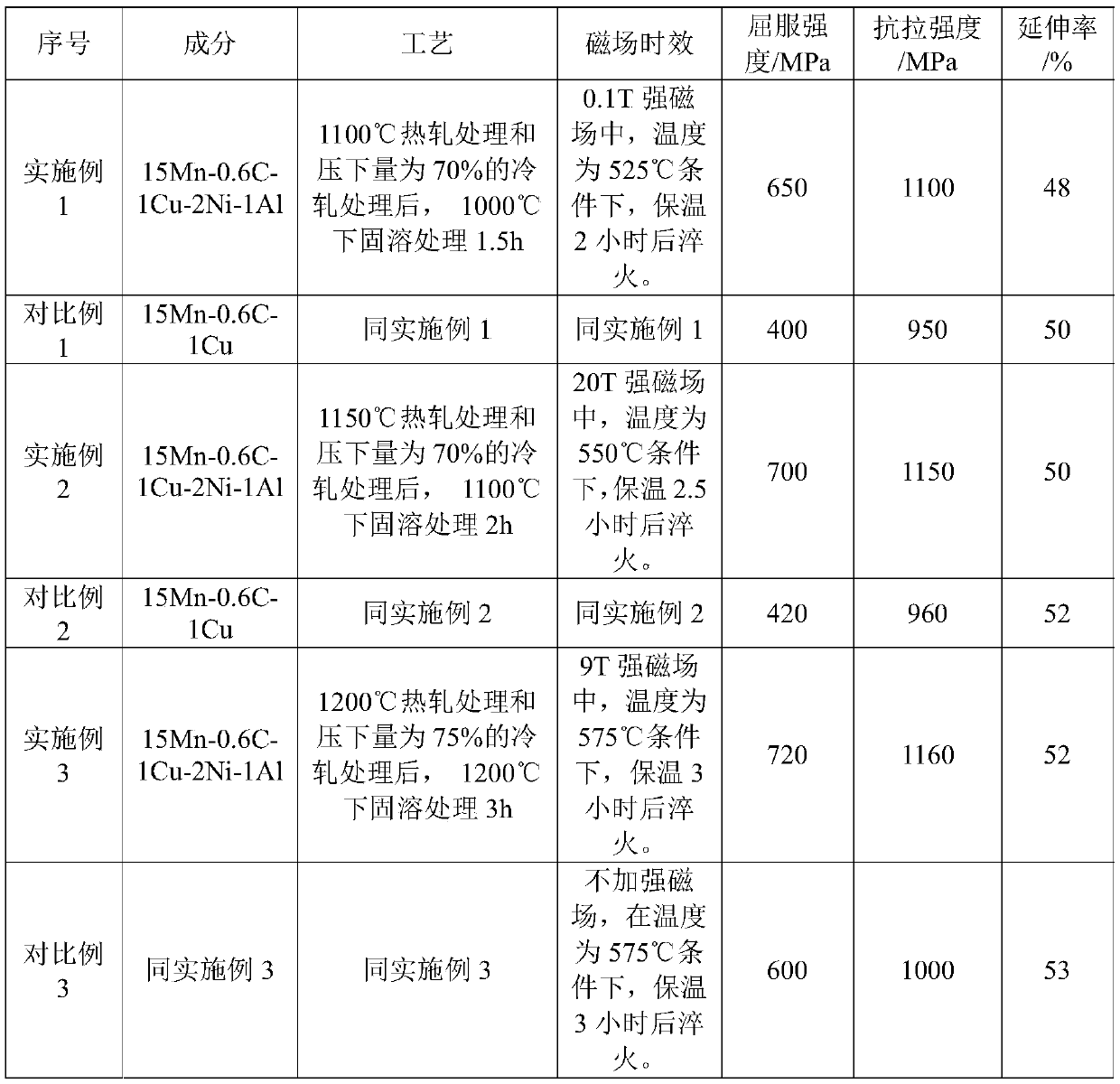

[0043] The tensile strength of the prepared 15Mn-0.6C-1Cu-2Ni-1AlTWIP steel is 1100MPa, the elongatio...

Embodiment 2

[0048] (1) Master alloy preparation: use high-purity metals or powders such as Fe, Mn, Cu, Al, Ni and C with a purity ≥ 99.9 wt%, and smelt the metals in a vacuum induction furnace. During the smelting process, 1.5Hz low-frequency electromagnetic stirring is applied, and the alloy ingot is prepared by casting in a copper mold under the protection of 0.1 standard atmospheric pressure argon;

[0049] (2) Hot rolling, cold rolling and solution treatment: the TWIP steel obtained in step (1) is subjected to hot rolling treatment at 1150° C., and then after cold rolling treatment with a pass reduction of 70%, it is solidified at 1100° C. Dissolving treatment for 2h.

[0050] (3) Strong magnetic field aging treatment: place the sample obtained in step (2) in a 20T strong magnetic field, adjust the position of the sample, and heat it at 550°C for 2.5 hours before quenching to obtain TWIP steel.

[0051] The tensile strength of the prepared 15Mn-0.6C-1Cu-2Ni-1AlTWIP steel is 1150MPa, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com