Lean duplex stainless steel and method for producing same

A technology of duplex stainless steel and manufacturing method, applied in the field of economical duplex stainless steel, can solve problems such as steel coil cracks, achieve the effects of saving resources, excellent elongation and corrosion resistance, and reducing raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

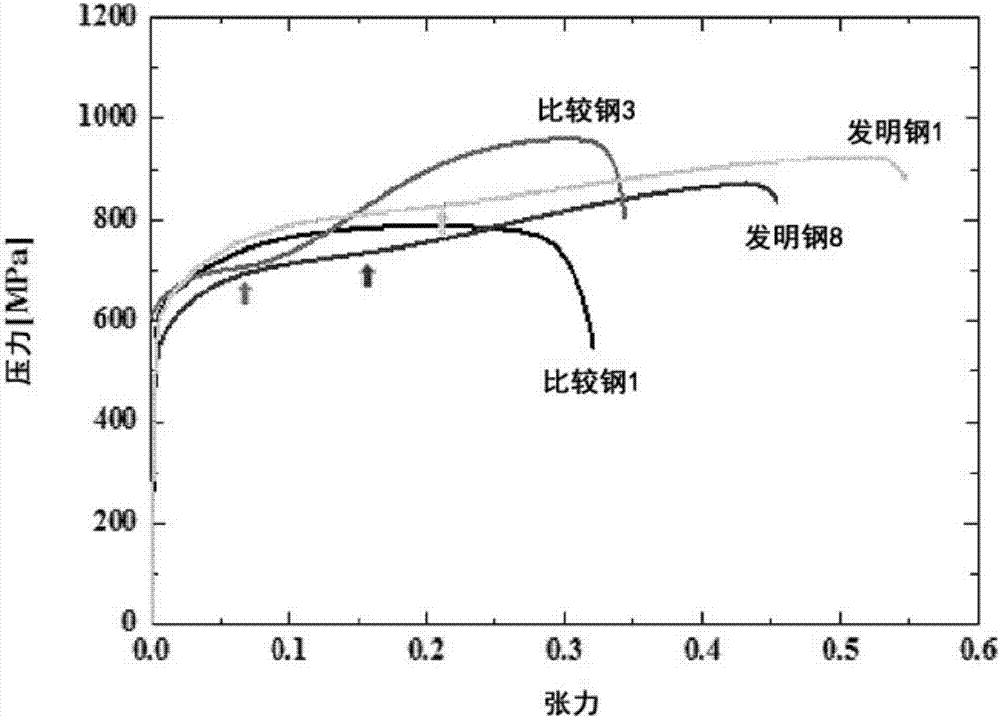

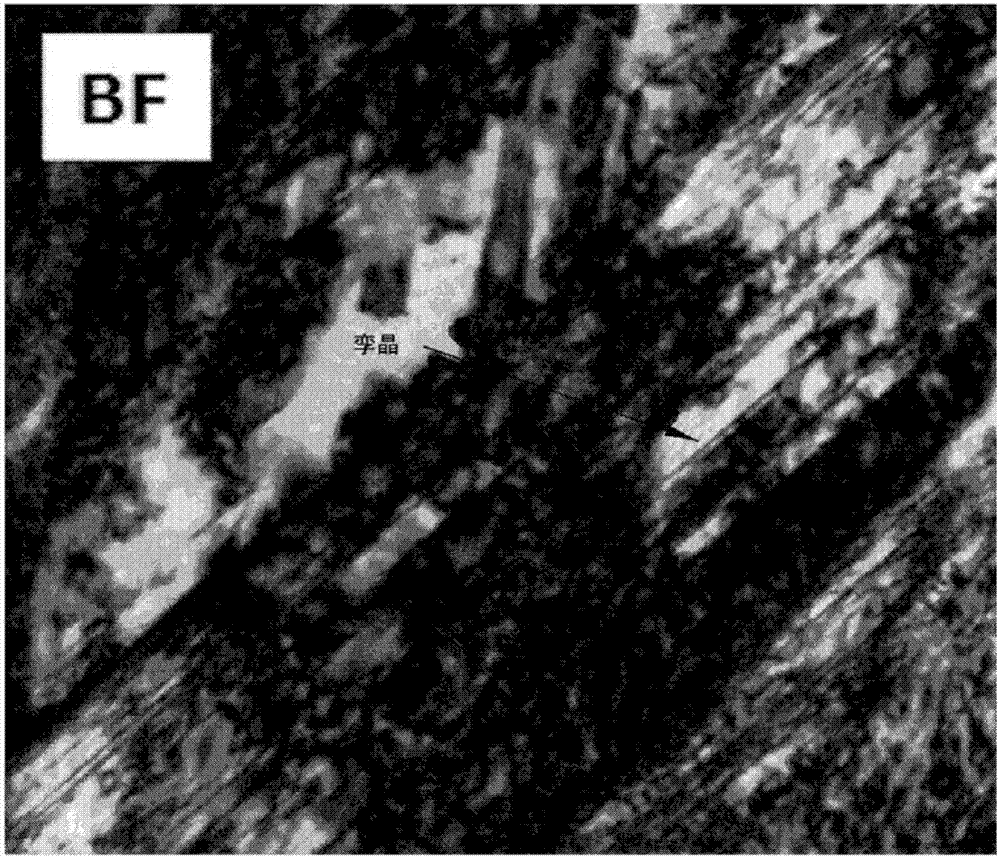

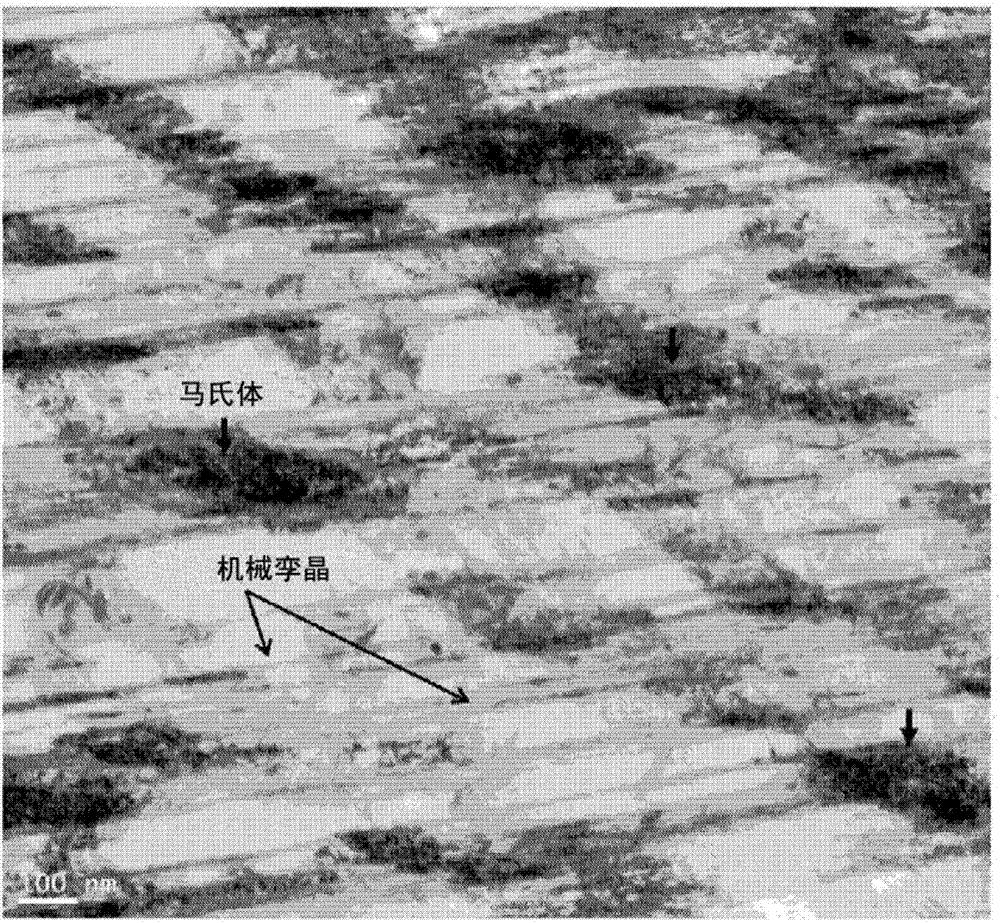

[0097] Below, the elongation and corrosion resistance will be described in detail through various embodiments of the economical duplex stainless steel of the present invention.

[0098] After preparing test pieces using molten steel adjusted to the composition content shown in Table 1 below, hot rolling, hot rolling annealing, and cold rolling annealing were performed after cold rolling to adjust the phase fraction of the material, thereby measuring elongation and corrosion resistance.

[0099]For the tensile test piece, after processing the ASTM-sub size test piece parallel to the rolling direction, adjust the rate of tensile deformation rate to 1.0×10 at room temperature -3 / s and measure. The following [Table 1] shows the alloy compositions (% by weight) for the experimental steel types.

[0100] In addition, the following [Table 2] shows the phase fractions of the ferrite phase and the austenite phase measured after annealing heat treatment at 1100° C. for some of the exp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com