Method for producing a motor vehicle component and motor vehicle component

A technology for motor vehicles and components, applied in the direction of manufacturing tools, heat treatment equipment, quenching devices, etc., can solve the problems of high strength and limited ductility of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

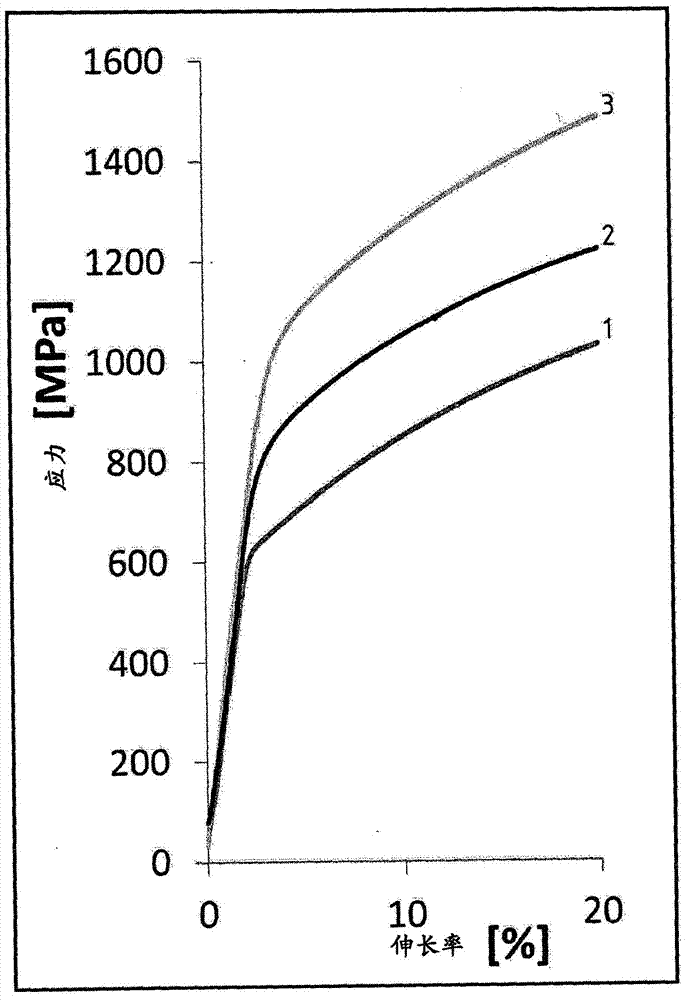

[0048] figure 1 Stress-strain diagrams are shown for steels formed according to the invention, where three different cold forming temperatures were chosen. It can be seen that the lower the selected cold forming temperature, the greater the increase in tensile strength. Thus, the steel of curve 1 is formed at room temperature and thus substantially at 20°C. The material in curve 2 was formed at -110.15°C and had significantly higher tensile strength than that formed at room temperature. The component according to curve 3 was formed at -196.15° C. and had a further significantly increased tensile strength.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield point | aaaaa | aaaaa |

| yield point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com