High-plasticity and high-strength high-entropy alloy and preparation method thereof

A high-entropy alloy and high-strength technology, applied in the field of high-entropy alloys, can solve the problem that high-entropy alloys cannot have both high plasticity and high strength at the same time, and achieve the effect of simple preparation method and strong process controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

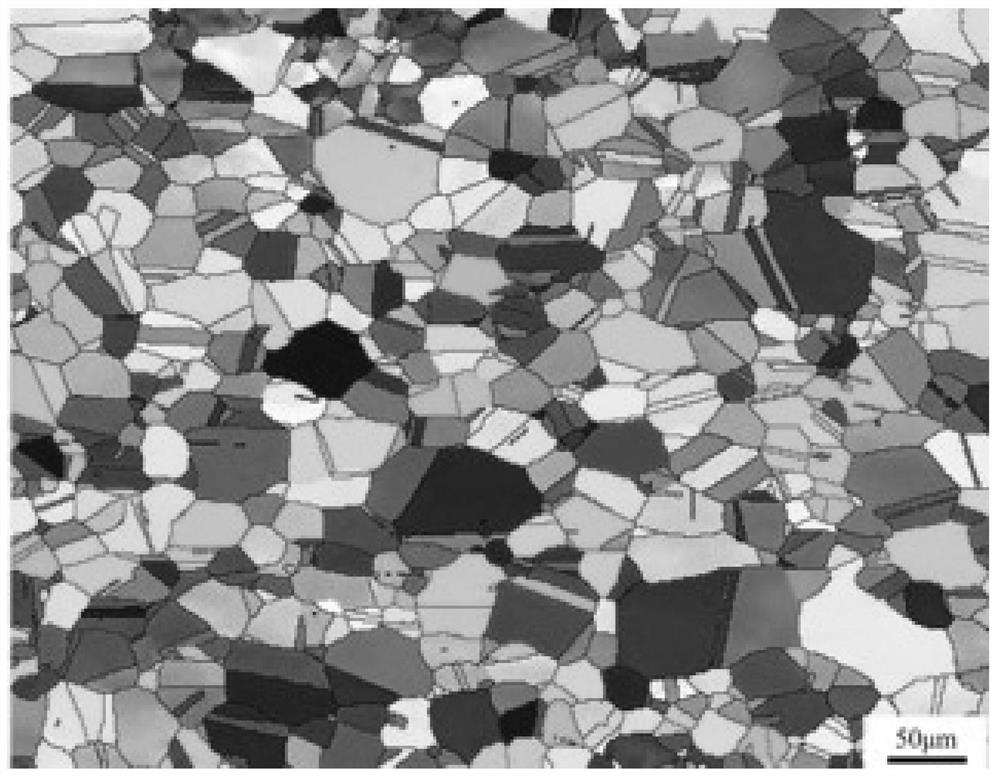

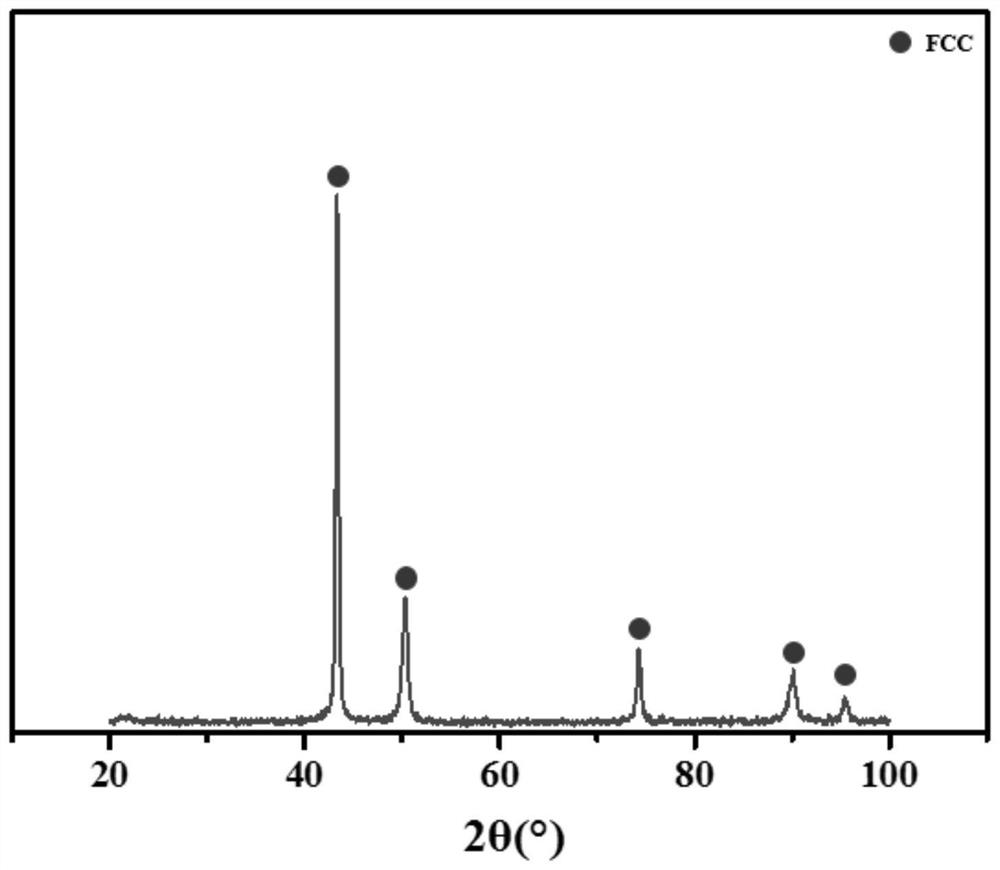

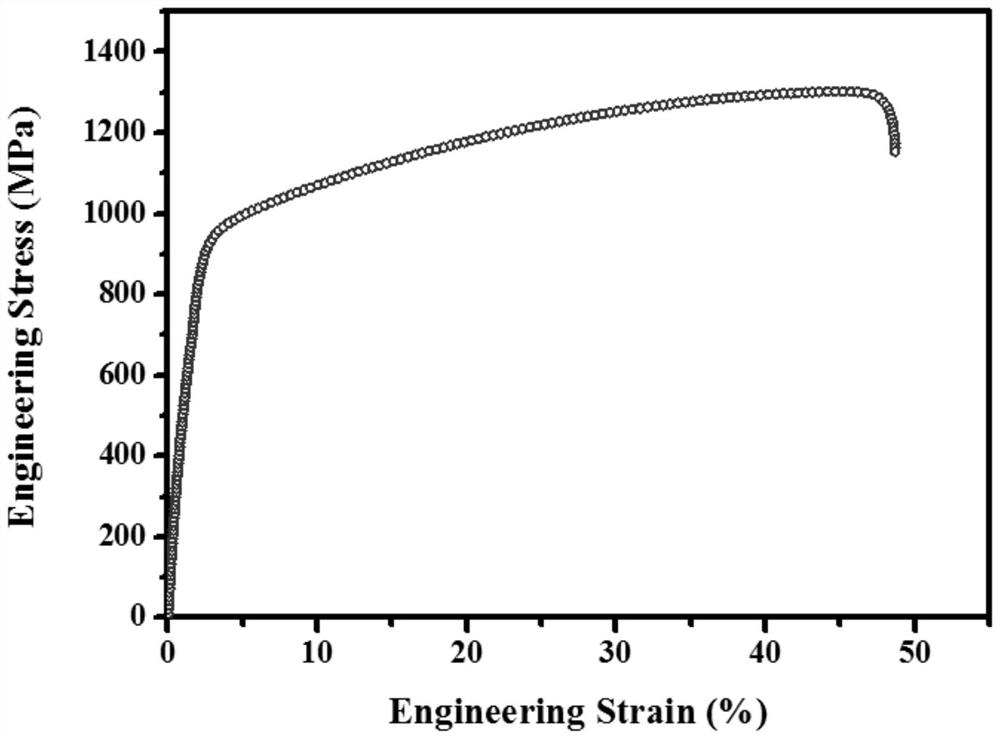

Embodiment 1

[0032] Metal nickel, metal cobalt, metal iron, metal niobium, and metal vanadium are selected, and the composition of the high-entropy alloy is as follows (atomic percent): Ni=40.0, Co=27.0, Fe=27.0, Nb=3.0, V=3.0.

[0033] Cast alloy ingots by arc melting or induction melting; smelting is carried out in vacuum or argon protection, and magnetic stirring technology is used to mix the metal solution evenly during the melting process; protection casting is carried out under vacuum or argon protection, and the size is cast into square or round ingot;

[0034] The ingot and billet are heated to 1300±10°C, held for 10 hours and then quenched;

[0035] Cold rolling the cast ingot and slab at room temperature, the first large deformation cold rolling amount is 60%;

[0036] Perform intermediate annealing at 1200±10°C for large-deformation cold-rolled plates, hold for 3 hours, and then quench;

[0037] Carry out cold rolling with a small deformation of 5% again on the plate after int...

Embodiment 2

[0042] Metal nickel, metal cobalt, metal iron, metal niobium, and metal vanadium are selected, and the composition of the high-entropy alloy is as follows (atomic percent): Ni=30.0, Co=25.0, Fe=25.0, Nb=10.0, V=10.0.

[0043] Cast alloy ingots by arc melting or induction melting; smelting is carried out in vacuum or argon protection, and magnetic stirring technology is used to mix the metal solution evenly during the melting process; protection casting is carried out under vacuum or argon protection, and the size is cast into square or round ingot;

[0044] The ingot casting billet is heated to 1000±10°C, kept for 24 hours and then quenched;

[0045] Cold rolling the cast ingot and slab at room temperature, the first large deformation cold rolling amount is 85%;

[0046] Perform intermediate annealing at 1000±10°C for large-deformation cold-rolled plates, hold for 3 hours, and then quench;

[0047] Carry out cold rolling with a small deformation of 9% again on the plate afte...

Embodiment 3

[0052] Metal nickel, metal cobalt, metal iron, metal niobium, and metal vanadium are selected, and the composition of the high-entropy alloy is as follows (atomic percent): Ni=35.0, Co=27.5, Fe=27.5, Nb=5.0, V=5.0.

[0053] Cast alloy ingots by arc melting or induction melting; smelting is carried out in vacuum or argon protection, and magnetic stirring technology is used to mix the metal solution evenly during the melting process; protection casting is carried out under vacuum or argon protection, and the size is cast into square or round ingot;

[0054] The ingot and billet are heated to 1200±10°C, kept for 15 hours and then quenched;

[0055] Cold rolling the cast ingot and slab at room temperature, the first large deformation cold rolling amount is 90%;

[0056] Perform intermediate annealing at 1200±10°C for large-deformation cold-rolled plates, holding time for 1h, and then quenching;

[0057] Carry out cold rolling with a small deformation of 10% again on the plate af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com