High-manganese TWIP (Twining Induced Plasticity) low temperature resistant steel with high impact toughness and manufacturing method thereof

A low-temperature-resistant, high-impact technology, applied in the field of high-manganese TWIP low-temperature-resistant steel and its manufacturing, can solve the problems of high price and complicated smelting process, and achieve the effect of simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

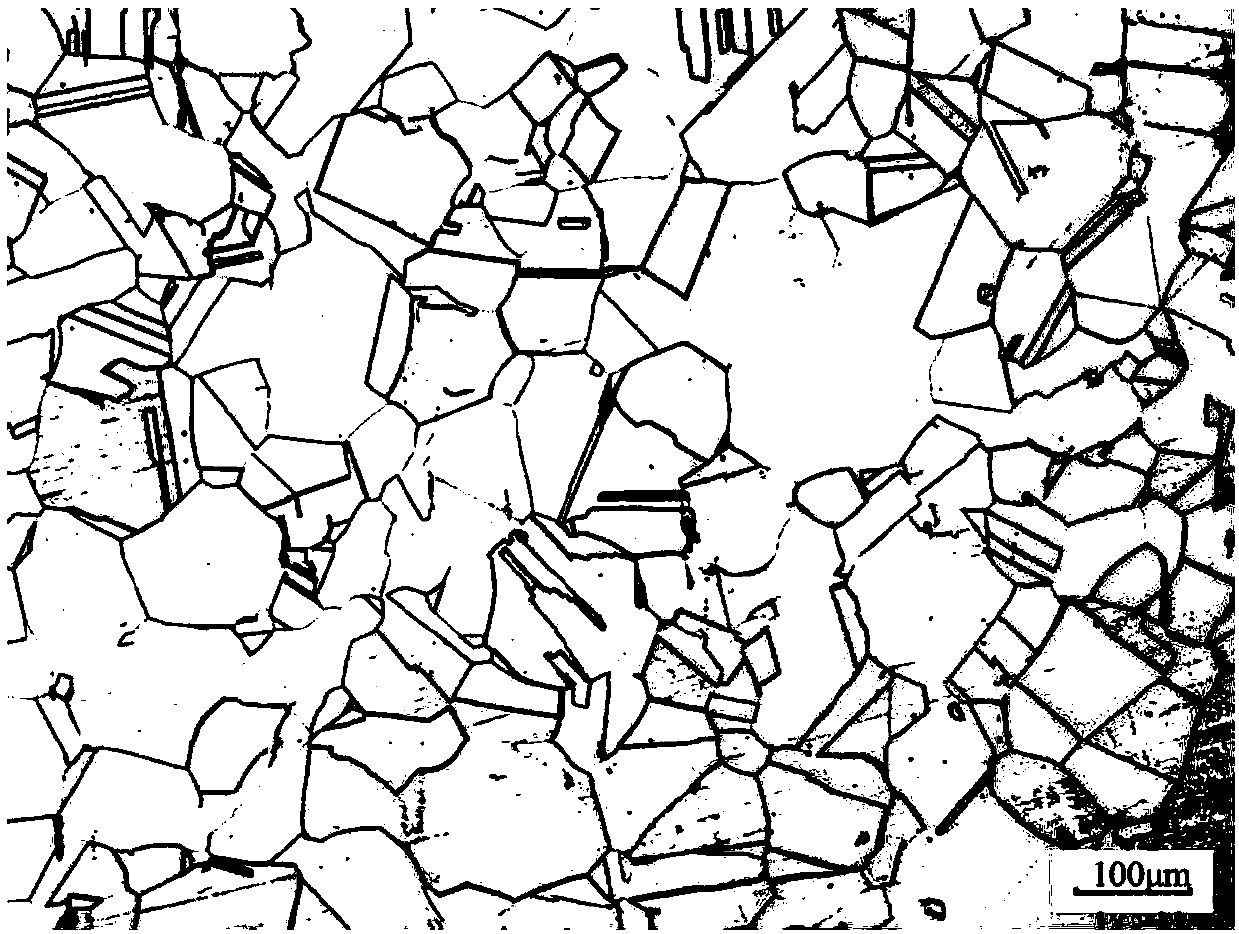

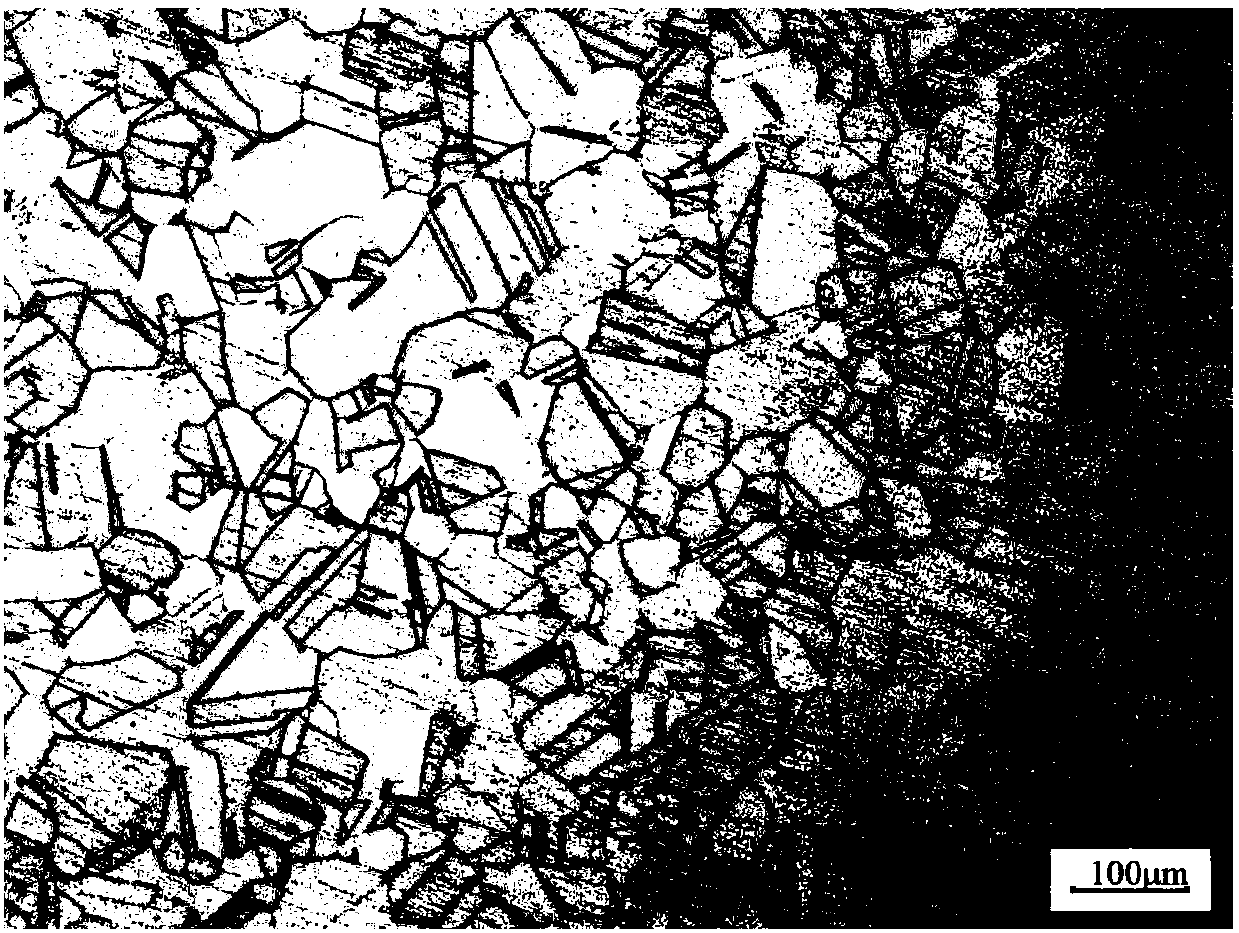

[0038] The chemical composition and mass percentage of the high-manganese TWIP low-temperature steel designed in this implementation are: C: 0.10%, Mn: 31%, Si: 0.35%, Al: 4.0%, and the rest is Fe. The estimated stacking fault energy at -196°C is 30.11mJ / m 2 .

[0039] The production method of high manganese TWIP low-temperature steel in this embodiment includes smelting, continuous casting, heating and rolling operations, and the specific process steps are as follows:

[0040] (1) Smelting process: Mn, Al, and Si elements are prepared according to the ratio of 104%, 110%, and 102% of the target mass fractions, and are smelted in a 50-ton converter. First add desulfurized and desiliconized molten iron into the furnace, the molten iron contains S: 0.006%, Si: 0.080%. Oxygen blowing smelting, the chemical composition of the smelting end point is as follows: C: 0.03%, Si: 0.07%, Mn: 0.12%, S: 0.003%, P: 0.002%. Add ferromanganese alloy, ferrosilicon alloy and pure aluminum to ...

Embodiment 2

[0081] The chemical composition and mass percentage of high-manganese TWIP low-temperature steel designed for this implementation are: C: 0.30%, Mn: 35%, Si: 1.5%, Al: 2.5%, and the rest is Fe and unavoidable impurities. The estimated stacking fault energy at -196°C is 28.28mJ / m 2 .

[0082] The production method of high manganese TWIP low-temperature steel in this embodiment includes smelting, continuous casting, heating and rolling operations, and the specific process steps are as follows:

[0083] (1) Smelting process: Mn, Al, and Si elements are prepared according to the ratio of 105%, 107%, and 102% of the target mass fraction, and are prepared for feeding according to the above-mentioned mass ratio, and are smelted in a 3-ton electric arc furnace. First add selected steel scrap into the furnace, S: 0.008% and P: 0.09% in the steel scrap. After the scrap steel is melted, the weighed ferrosilicon and ferromanganese alloys are added sequentially for alloying; after the adde...

Embodiment 3

[0093] The chemical composition and mass percentage of the high-manganese TWIP low-temperature steel designed for this implementation are: C: 0.12%, Mn: 32%, Si: 1.0%, Al: 3.5%, and the rest is Fe. The estimated stacking fault energy at -196°C is 25.54mJ / m 2 .

[0094] The production method of high manganese TWIP low-temperature steel in this embodiment includes smelting, continuous casting, heating and rolling operations, and the specific process steps are as follows:

[0095] (1) Smelting process: Mn, Al, and Si elements are prepared according to the proportion of 106%, 106% and 108% of the target mass fractions, and are prepared according to the above mass proportions, and are smelted in a 50-ton converter. First add desulfurized and desiliconized molten iron into the furnace, the molten iron contains S: 0.007%, Si: 0.080%. Oxygen blowing smelting, the chemical composition of the smelting end point is as follows: C: 0.04%, Si: 0.08%, Mn: 0.14%, S: 0.005%, P: 0.004%. Add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com