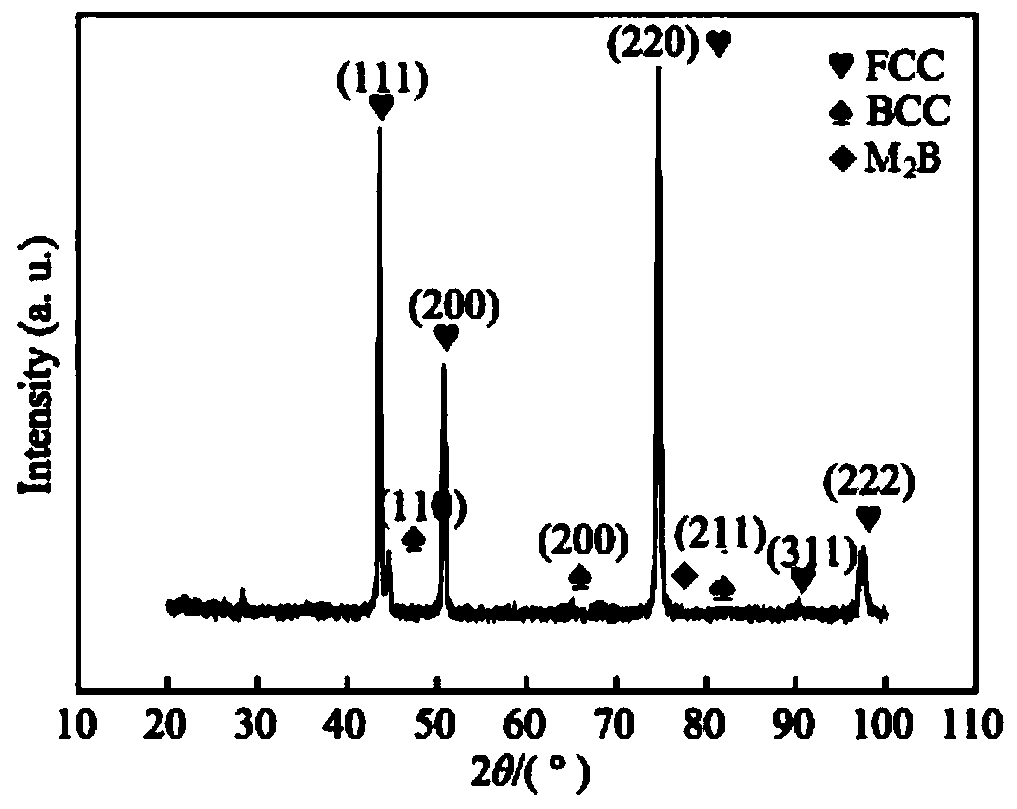

Boron-containing high-entropy alloy coating and preparation method thereof

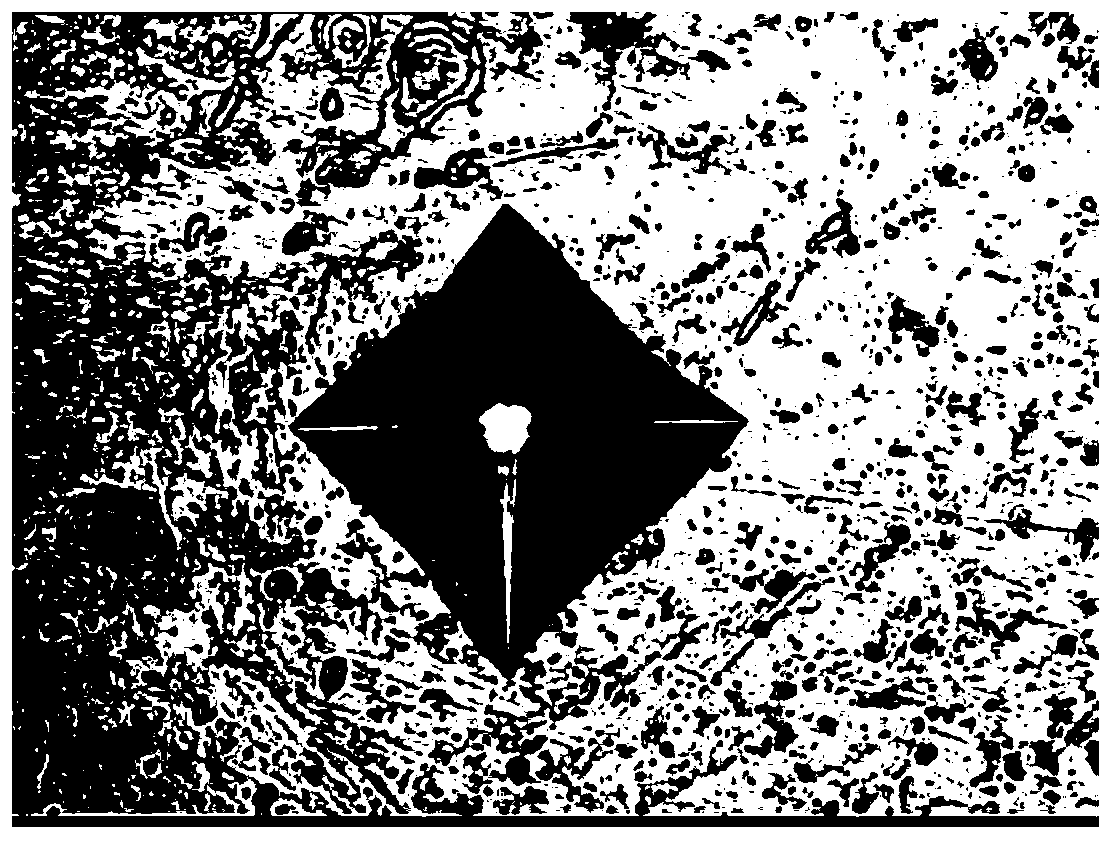

A high-entropy alloy and coating technology, applied in metal material coating process, coating and other directions, can solve problems such as poor hardness of high-entropy alloy coating, improve surface morphology, reduce inclusion and oxygen content, The effect of increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

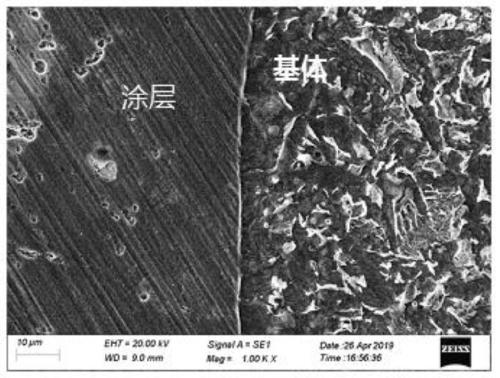

[0026] The present invention also provides a method for preparing a boron-containing high-entropy alloy coating described in the above technical solution, comprising the following steps:

[0027] Co powder, Cr powder, Cu powder, Fe powder, Mn powder and ferroboron powder are mixed and homogenized to obtain mixed powder;

[0028] drying the mixed powder to obtain a dry powder;

[0029] The dry powder is subjected to plasma cladding on the surface of the substrate to obtain the boron-containing high-entropy alloy coating.

[0030] The invention mixes Co powder, Cr powder, Cu powder, Fe powder, Mn powder and ferroboron powder and performs homogenization treatment to obtain the mixed powder. In the present invention, the particle size of the Co powder, Cr powder, Cu powder, Fe powder and Mn powder is independently preferably 80-200 mesh, more preferably 100-150 mesh, and the Co powder, Cr powder, Cu powder , the purity of Fe powder and Mn powder are preferably greater than 99.9%...

Embodiment 1

[0039] Co, Cr, Cu, Fe, Mn as the main element powder, the purity of the powder is greater than 99.9%, and the particle size is between 100 and 150 mesh;

[0040] Select B as the secondary element powder, and B is added in the form of ferroboron powder (the mass fraction of each element in the ferroboron powder is: 20% B, 0.5% C, 4.0% Si, 0.2% P, 0.5% Al, and the balance Fe) , the purity of the powder is greater than 98%, and the particle size is between 100 and 150 mesh;

[0041] Mixed powder ratio, after the main element powders Co, Cr, Cu, Fe, Mn are mixed, the ferroboron powder is added to the main element mixed powder, and then poured into a high-energy machine for homogenization treatment, so that Co, Cr, Fe, and Mn in the final coating The molar ratio of Cr, Cu, Fe, Mn and B is 1:1:1:1:1:0.1. Ball milling parameters: the ball-to-material ratio is 10:1, the ball mill speed is 200r / min, the ball milling time is 2h, argon protection is carried out during the ball milling p...

Embodiment 2

[0048] Co, Cr, Cu, Fe, Mn as the main element powder, the purity of the powder is greater than 99.9%, and the particle size is between 80 and 200 mesh;

[0049] Select B as the secondary element powder, and B is added in the form of ferroboron powder (the mass fraction of each element in the ferroboron powder is: 20% B, 0.5% C, 4.0% Si, 0.2% P, 0.5% Al, and the balance Fe) , the purity of the powder is greater than 98%, and the particle size is between 80 and 200 mesh;

[0050] Mixed powder ratio, after the main element powders Co, Cr, Cu, Fe, Mn are mixed, the ferroboron powder is added to the main element mixed powder, and then poured into a high-energy machine for homogenization treatment, so that Co, Cr, Fe, and Mn in the final coating The molar ratio of Cr, Cu, Fe, Mn and B is 1:1:1:1:1:0.4. Ball milling parameters: the ratio of ball to material is 10:1, the rotational speed of the ball mill is 100r / min, the ball milling time is 4h, and argon protection is carried out du...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Average hardness | aaaaa | aaaaa |

| Average hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com