Electric vehicle battery system that can be increased or decreased by using the lower body as the battery box

A technology for electric vehicle batteries and battery boxes, which is applied in the directions of batteries, electric power devices, battery pack components, etc., can solve the problems of higher structure and performance requirements, waste of space structure, etc., and achieve the effect of being conducive to expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following description is merely exemplary in nature and not intended to limit the disclosure, application or use. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

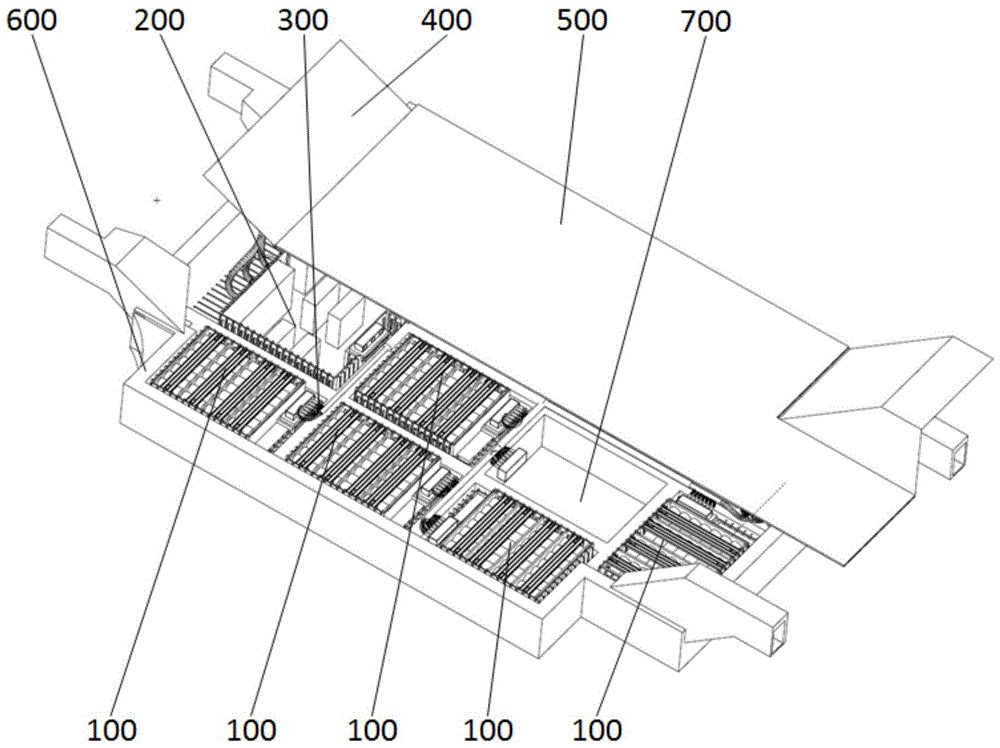

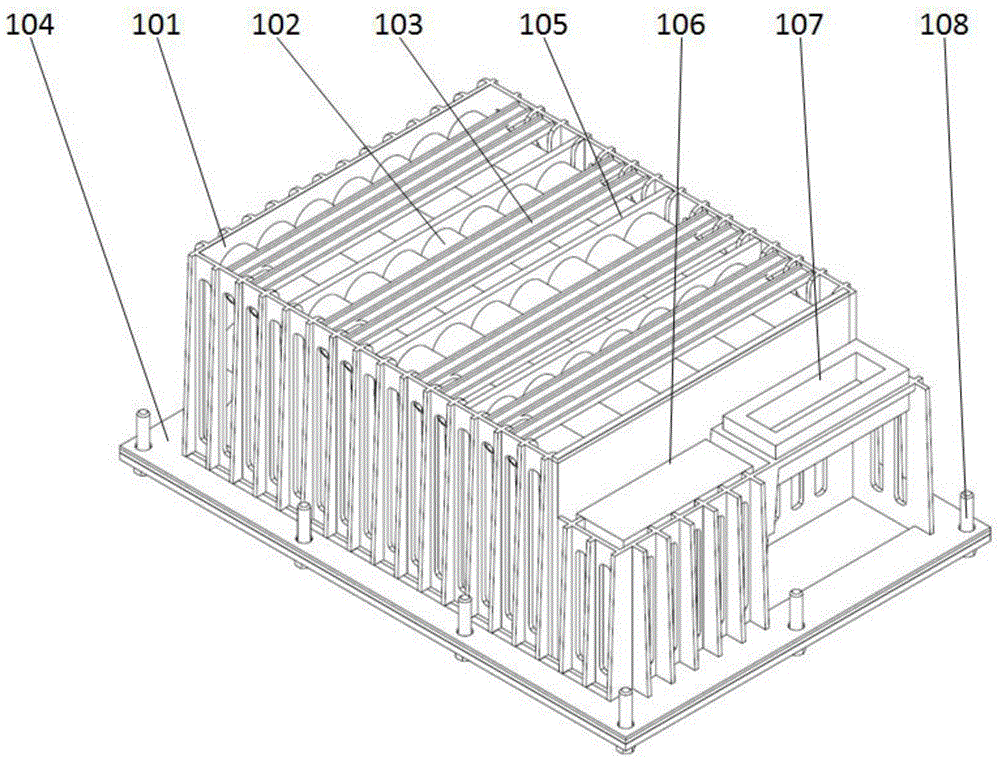

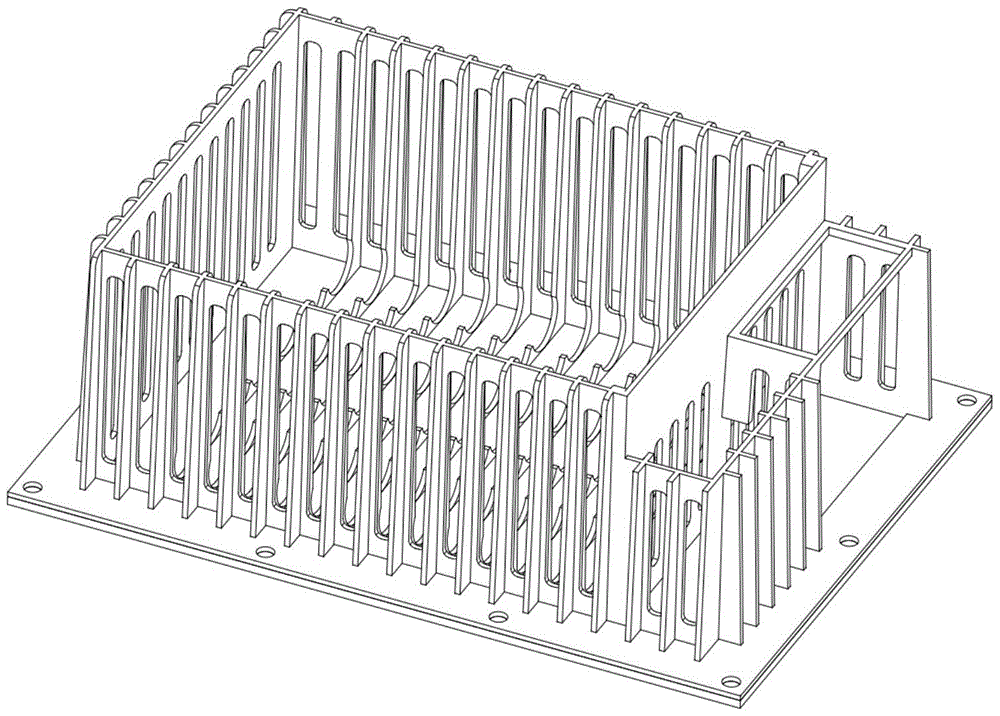

[0048] Such as figure 1 As shown, the electric vehicle battery system that can be increased or decreased using the lower vehicle body as the battery box according to the present invention includes a single battery pack 100, a main control box 200, a connecting wire harness 300, a lower floor 400, an upper floor 500, a lower floor Car body 600, sealing plate 700 seven big parts. The single battery pack 100 is connected to the lower body 600 through bolts 108, the main control box 200 is connected to the lower body 600 through bolts 108, the underfloor 400 and the lower body 600 are welded together, relatively fixed, and the single battery pack connector (male plug) 301 is installed on the lower floor 400 through thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com