Light-weight heat-conducting organosilicon pouring sealant base sizing material as well as composition and preparation methods thereof

A silicone potting compound and lightweight technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problem of uniform thermal conductivity, achieve good fluidity, fast molding speed, and improve thermal conductivity performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

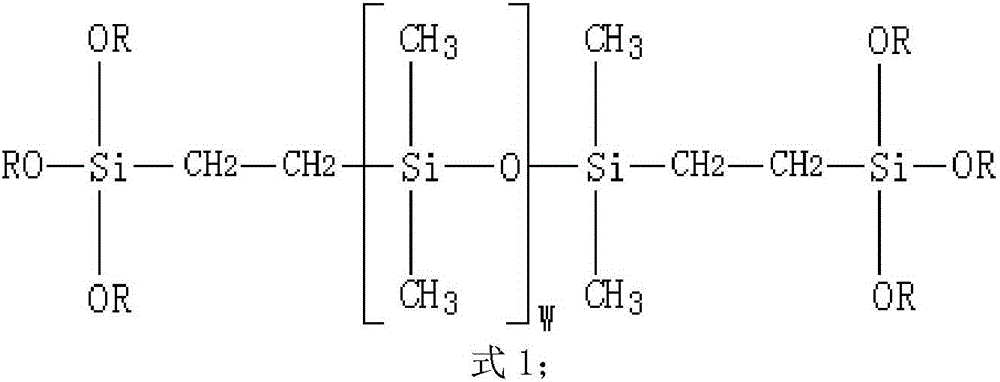

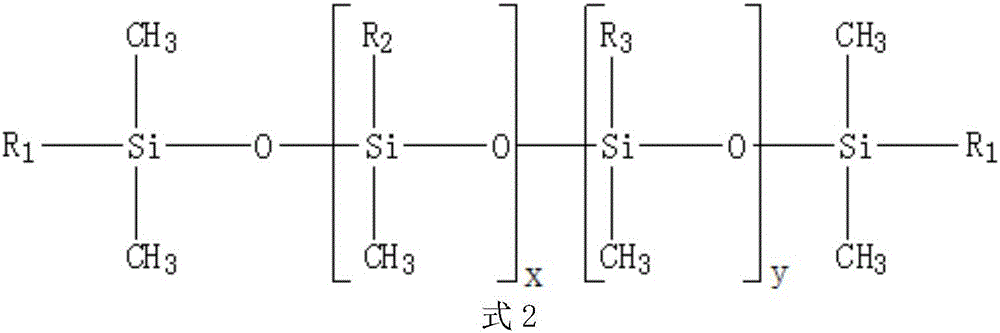

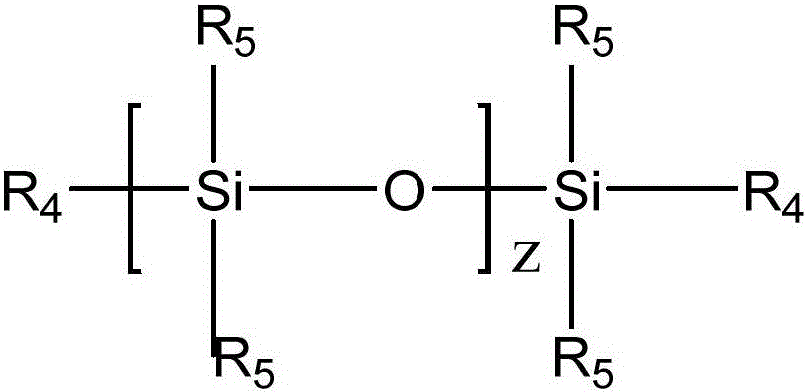

Method used

Image

Examples

Embodiment 1

[0065] Add 100 parts by mass of the unsaturated hydrocarbon group-terminated polydiorganosiloxane (a) and 0 parts by mass of the saturated hydrocarbon group-terminated polydiorganosiloxane (b) into the vacuum kneader, and divide it several times Add 50 parts by mass, particle size is 1um, density is 0.4g / cm 3 Hollow glass microsphere thermally conductive filler (c), 30 parts by mass of aluminum hydroxide flame-retardant filler (d) with a particle size of 5um and 10 parts by mass of 3-glycidoxypropyltrimethoxysilane treatment agent (e) , Stir and mix for 1.0 hour, then add 0 parts by mass of alkoxy-terminated polydimethylsiloxane (f), continue to stir and mix for 0.5 hours; increase the temperature to 120°C and heat and mix for 2.0 hours; remove the low molecular weight by vacuum 1.0 Hours; After cooling and filtering, it is made into a lightweight, thermally conductive, flame-retardant silicone potting base compound.

[0066] Add 100 parts by mass of the above silicone potting ba...

Embodiment 2

[0079] Add 100 parts by mass of the unsaturated hydrocarbon group-terminated polydiorganosiloxane (a) and 20 parts by mass of the saturated hydrocarbon group-terminated polydiorganosiloxane (b) into the vacuum kneader, and divide it several times Add 1 part by mass, particle size is 5um, density is 2.0g / cm 3 Hollow ceramic microsphere thermally conductive filler (c), 90 parts by mass of magnesium hydroxide flame-retardant filler (d) with a particle size of 2um and 5 parts by mass of 3-glycidoxypropylmethyldiethoxysilane treatment agent (e), stir and mix for 2.0 hours, then add 8 parts by mass of alkoxy-terminated polydimethylsiloxane (f), continue to stir and mix for 0.8 hours; increase the temperature to 130°C and heat and mix for 3.0 hours; vacuum removal Low molecular weight for 2.0 hours; after cooling and filtering, it is made into a lightweight, thermally conductive, flame-retardant silicone potting base compound.

[0080] Add 100 parts by mass of the aforementioned silicon...

Embodiment 3

[0092] Add 100 parts by mass of the unsaturated hydrocarbon group-terminated polydiorganosiloxane (a) and 40 parts by mass of the saturated hydrocarbon group-terminated polydiorganosiloxane (b) into the vacuum kneader, and divide it several times Add 25 parts by mass, particle size is 20um, density is 0.1g / cm 3 Hollow alumina microsphere thermal conductive filler (c), 5 parts by mass of aluminum hydroxide flame-retardant filler (d) with a particle size of 2um, and 7 parts by mass of 3-glycidyl ether oxypropyl trimethoxysilane treatment agent (e ), stir and mix for 0.8 hours, then add 5 parts by mass of alkoxy-terminated polydimethylsiloxane (f), continue to stir and mix for 0.8 hours; increase the temperature to 140°C and heat and mix for 4.0 hours; remove low molecular weight in vacuum 3.0 hours; After cooling and filtering, it is made into a lightweight, thermally conductive, flame-retardant silicone potting base compound.

[0093] Add 100 parts by mass of the aforementioned si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com