Ethylene propylene diene rubber composition and preparation method

A technology of EPDM rubber and composition, which is applied in the formulation and preparation of EPDM rubber and carbon black nano-composite materials, and can solve the problems of low tensile strength, unsuitable related properties, and limited application of sealing materials, etc. Problems, to achieve the effect of high elongation at break, high tensile strength, low compression set characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

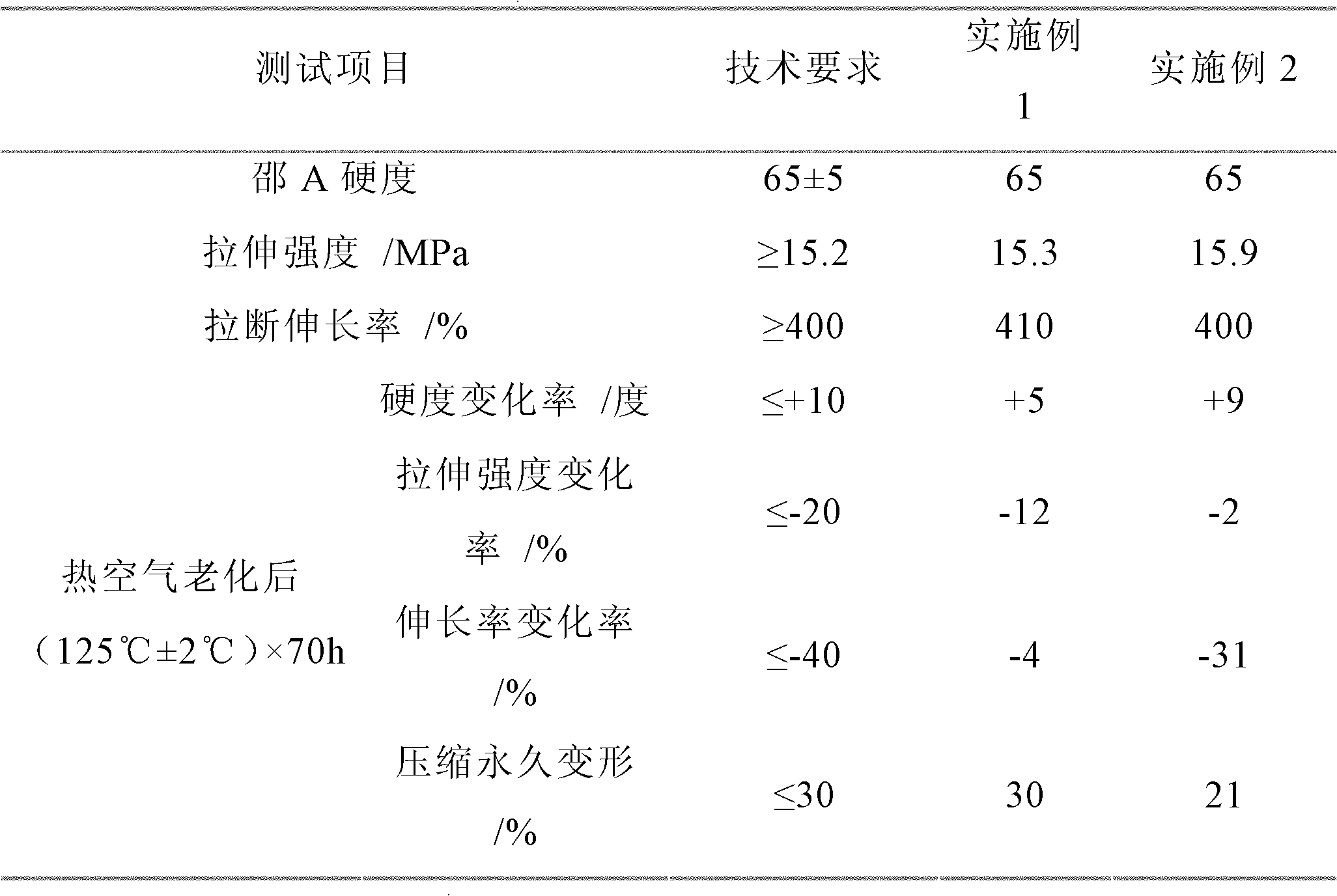

Embodiment 1

[0032] Embodiment 1: Formula composition: EPDM rubber (EXXON) 100 parts; Zinc oxide 10 parts; Stearic acid 0.5 part; Anti-aging agent RD 1.5 parts; Anti-aging agent MB 1.5 parts; Carbon black 65 parts; Plasticizer 15 parts Parts (5 parts of hydroxyl-terminated polybutadiene liquid rubber, 10 parts of paraffin oil); 5.5 parts of accelerator (0.5 parts of EZ, 1 part of DTDM, 4 parts of liquid TAIC); 5 parts of vulcanizing agent DCP; 0.3 parts of sulfur.

Embodiment 2

[0033] Embodiment 2: Formula composition: EPDM rubber (LANXESS) 100 parts; Zinc oxide 10 parts; Stearic acid 0.5 part; Anti-aging agent RD 1.5 parts; Anti-aging agent MB 1.5 parts; Carbon black 65 parts; Plasticizer 13 parts Parts (5 parts of hydroxyl-terminated polybutadiene liquid rubber, 8 parts of paraffin oil); 7.2 parts of accelerator (0.5 parts of EZ, 1 part of DTDM, 5.7 parts of solid TAIC); 4 parts of vulcanizing agent DCP; 0.3 parts of sulfur.

[0034] The novel high tensile strength of above-mentioned embodiment gained, the preparation method of the EPDM rubber / carbon black nano-composite material of high elongation at break and low compression set all comprises the following steps: (1) EPDM The rubber is masticated in two stages on the rubber mixer, and the time interval between the two mastications is 1 day; (2) Add zinc oxide, stearic acid, anti-aging agent, Carbon black, thin pass 4 times, and make 4 triangle bags; (3) add plasticizer (hydroxyl-terminated polybu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| compression set | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com