Method for reinforcing concrete floor by H-shaped steel

A technology of H-beam and concrete, applied in the direction of building maintenance, construction, building structure, etc., to achieve the effect of simple process, fast speed and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

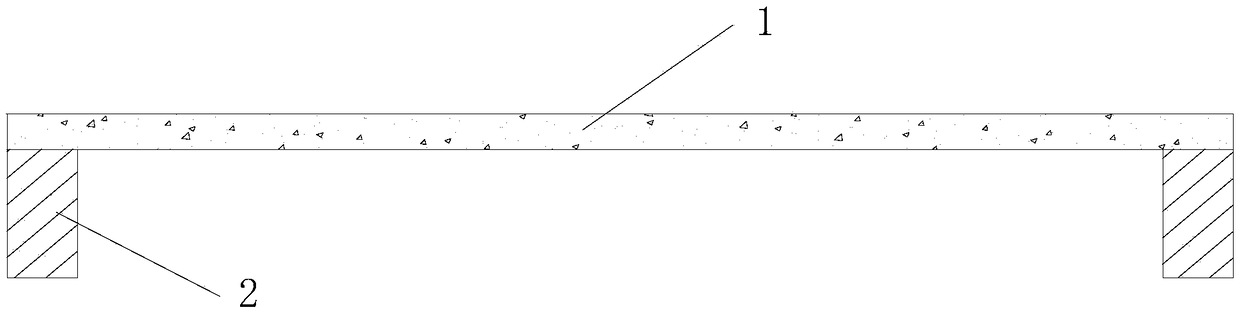

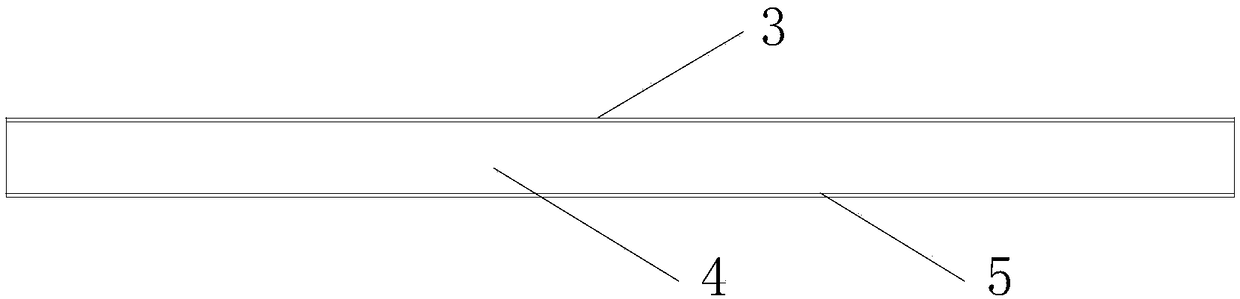

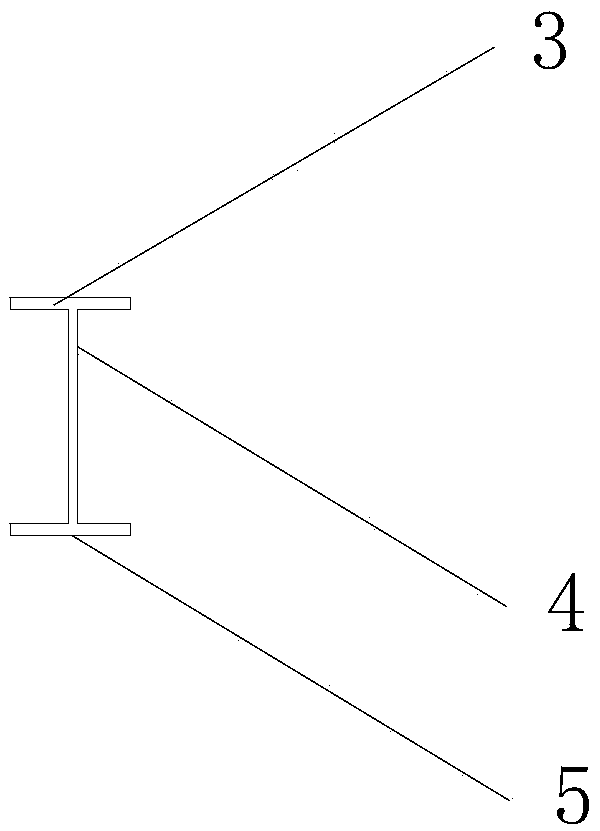

[0065] Such as Figure 1-9 , Shown in 13, a kind of method that penetrates floor bolt fastening method and strengthens concrete floor, comprises the steps:

[0066] (1) vertically offer a hole 6 through the floor slab on the floor 1 according to the design position, and the aperture of the hole is 1mm larger than the diameter of the screw rod 13 passing through the hole;

[0067] (2) Install a 4mm thick steel backing plate 12 at the perforated position on the upper surface of the floor 1. The width and length of the steel backing plate 12 are the same as the upper flange 3 of the H-shaped steel beam to be fixed; the steel backing plate 12 needs to be drilled before installation , the hole matches the size and position of the hole on floor 1;

[0068] (3) Thread the screw rod 13 into the holes of the floor and the backing plate, and screw the nut 10 at the end where the screw rod 13 is located on the upper surface of the floor, so that the screw rod 13 is fixed in the holes of...

Embodiment 2

[0077] Such as Figure 1-9 , Shown in 13, a kind of method that penetrates floor bolt fastening method and strengthens concrete floor, comprises the steps:

[0078] (1) Vertically offer a hole 6 through the floor slab on the floor 1 according to the design position, and the aperture of the hole is 2mm larger than the diameter of the screw rod 13 passing through the hole;

[0079] (2) Install a 7mm thick steel backing plate 12 on the upper surface of the floor 1 where holes are drilled. The width and length of the steel backing plate 12 are the same as the upper flange 3 of the H-shaped steel beam to be fixed; the steel backing plate 12 needs to be drilled before installation , the hole matches the size and position of the hole on floor 1;

[0080] (3) Thread the screw rod 13 into the holes of the floor and the backing plate, and screw the nut 10 at the end where the screw rod 13 is located on the upper surface of the floor, so that the screw rod 13 is fixed in the holes of th...

Embodiment 3

[0089] Such as Figure 1-6 As shown in and 10-13, a method for reinforcing a concrete floor slab by bolting bolts at the bottom of the slab comprises the following steps:

[0090] 1) According to the design position, on the lower surface of the floor 1, set up the bolting hole 8 driven into the bottom of the board vertically upwards, and the hole depth of the bolting hole 8 driven into the bottom of the board is 75% of the thickness of the floor 1; and The hole diameter of the bolting hole 8 driven into the bottom of the plate is 2 mm larger than the diameter of the screw 13 passing through the hole; after cleaning the hole, pour structural glue into the hole;

[0091] 2) implant one end of the screw rod 13 into the hole 6 punched through the floor in step 1), and the other end of the screw rod 13 is ready to install the H-shaped steel beam; the H-shaped steel beam is formed by the upper flange of the H-shaped steel beam 3. The web of the H-shaped steel beam 4 and the lower f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com