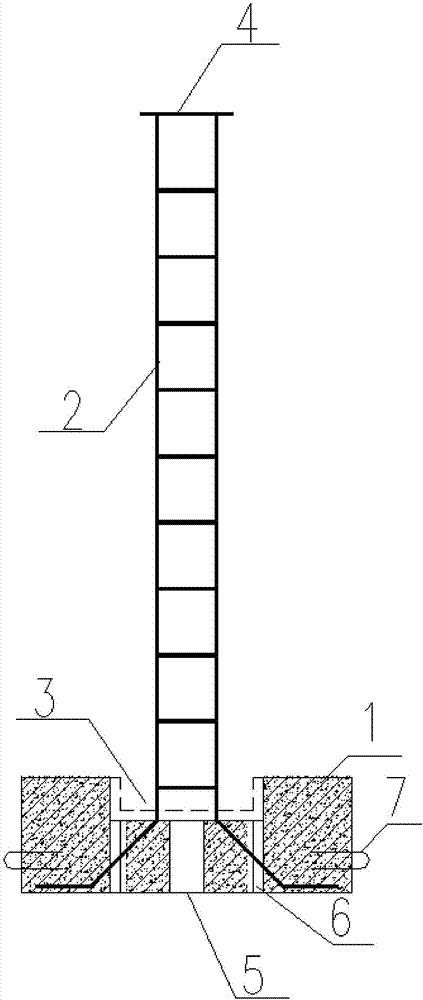

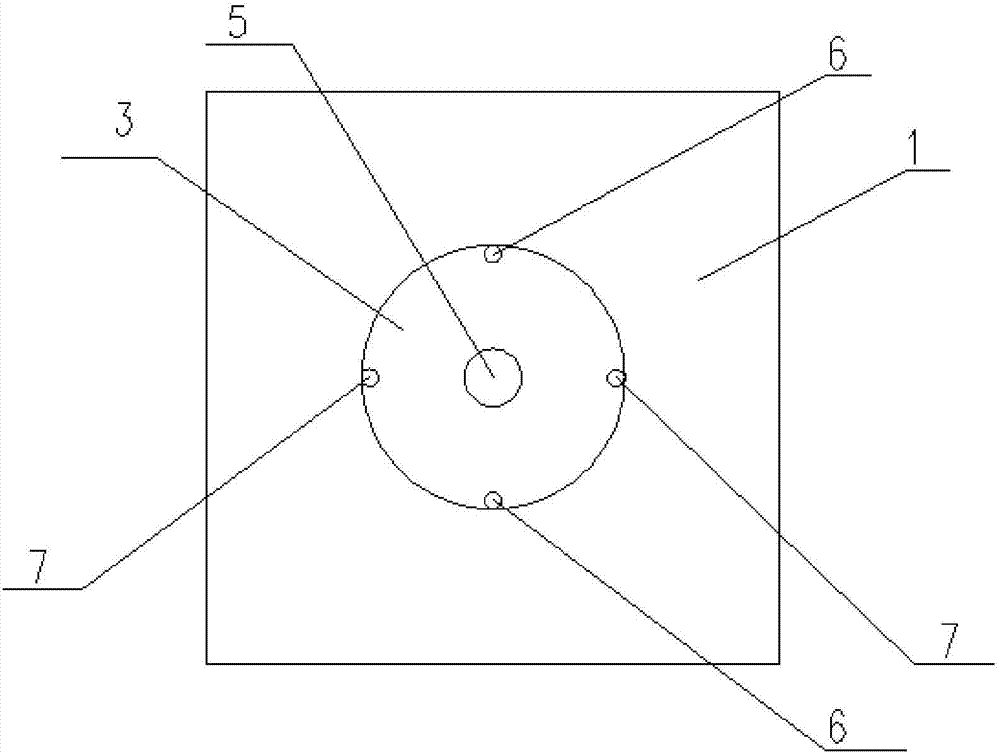

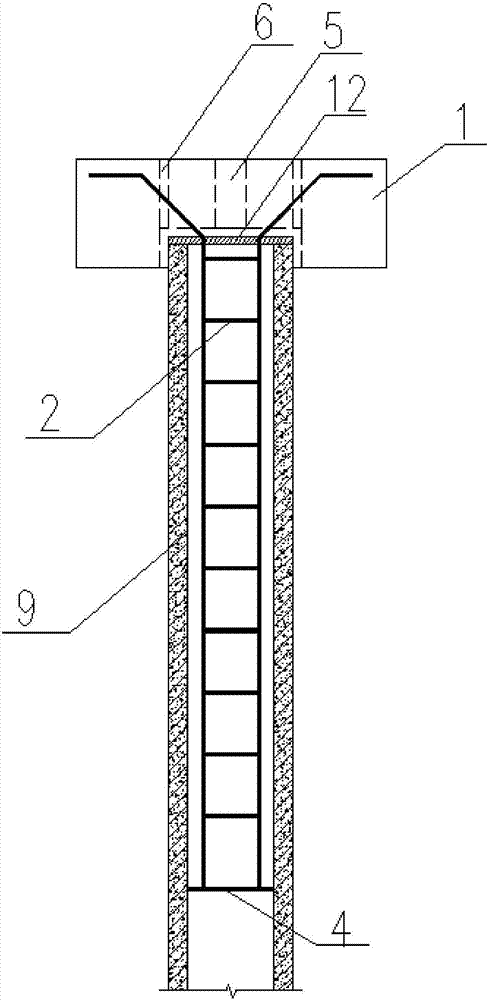

Prefabricated bearing platform with joint bar grouted core and construction process of prefabricated bearing platform

A prefabricated platform and core filling technology, applied in infrastructure engineering, construction, etc., can solve the problems of insufficient use of turnover materials such as formwork, large workload of formwork reinforcement, and many working surfaces of workers, so as to improve the construction site. progress, ensure construction quality, and improve the effect of economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The construction project consists of 2 warehouses (there are 6 management rooms in the warehouse), a property room and equipment room, two guards, and an elevated platform. The total construction area of this project is about 58,629 square meters, and the volumetric area is 107,527 square meters. Among them, A-1 warehouse and A-2 warehouse have 2 floors above the ground, the first floor is 10.3 meters high, and the second floor is 10.2 meters high. The seismic fortification intensity to be built is 7 degrees, and the design basic seismic acceleration is 0.10g, which is the first group of design seismic grouping. The elevation of ±0.000m is equivalent to the absolute elevation of 3.9m. It is planned to drive piles on the soft soil foundation inside the main body of A-1 storage. A prefabricated component to be processed, the code name is PST-CF, the pile type is: ZHa:PST-CF-400 (outer diameter)-60 (wall thickness)-9, * (two-section pile length), and the pile top elevat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com