Node crack prevention and reinforced structure of reinforced concrete and manufacture method thereof

A reinforced concrete and reinforced structure technology, applied in bridge reinforcement, building structure, building maintenance, etc., can solve the problems of special-shaped steel plates that are easy to peel off, fall off, and uneconomical, so as to avoid reinforcement and maintenance work, improve safety and durability, and strengthen The effect of concrete strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

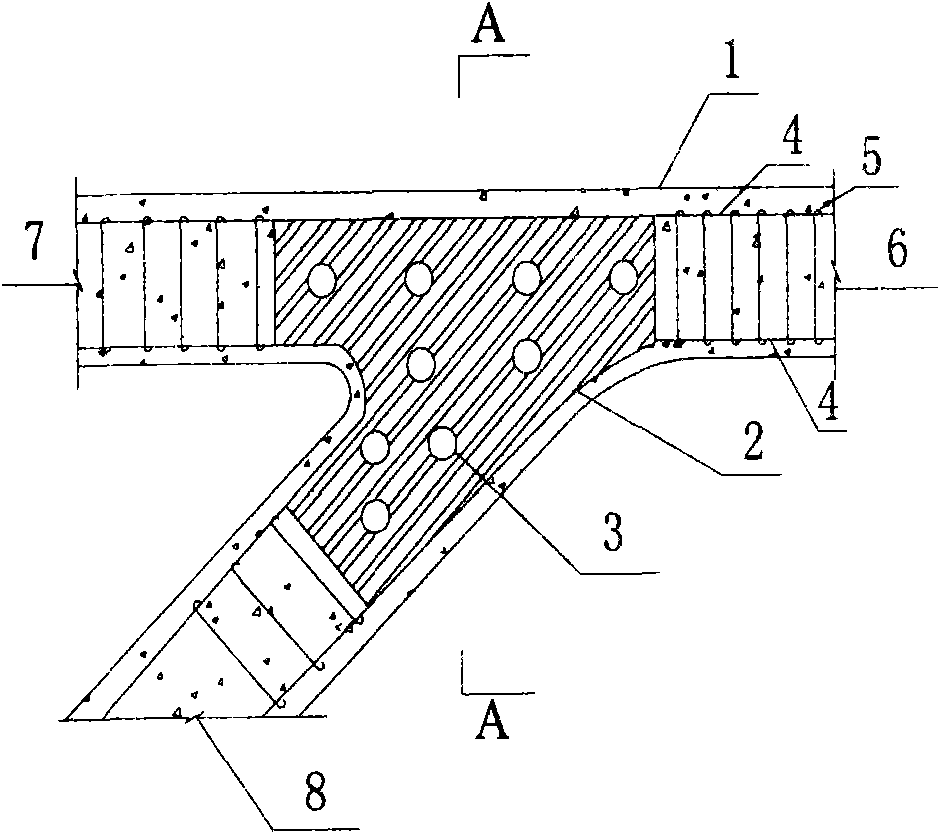

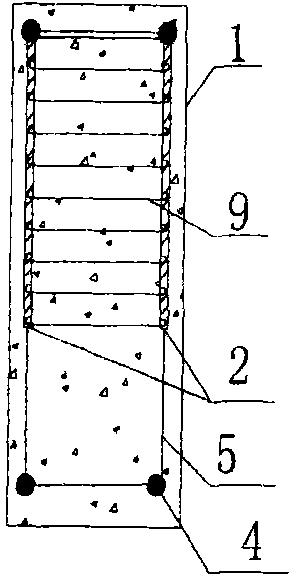

[0032] like figure 1 and figure 2 As shown, it is a schematic diagram of the T-shaped large node structure of the main arch rib of a rigid frame arch bridge. It can be seen from the figure that it includes the main arch leg 8, the side beam 7, the solid web section 6, the main reinforced steel bar 4, and the ordinary stirrup 5. The horizontal connecting stirrup 9 and the special-shaped steel plate 2 poured in the node, the special-shaped steel plate 2 should be spot-welded with the structural steel skeleton.

[0033] The thickness of the joint concrete protective layer 1 in this embodiment is 2.8cm, and a special-shaped steel plate 2 is arranged on each side of the joint, and the thickness of the special-shaped steel plate 2 is 6mm; since the maximum particle size of the concrete aggregate is 3.5cm, the special-shaped steel plates 2 are evenly arranged 9 boreholes with a diameter of 5cm and a hollowing rate of 30% to ensure that the concrete passes through the boreholes duri...

Embodiment 2

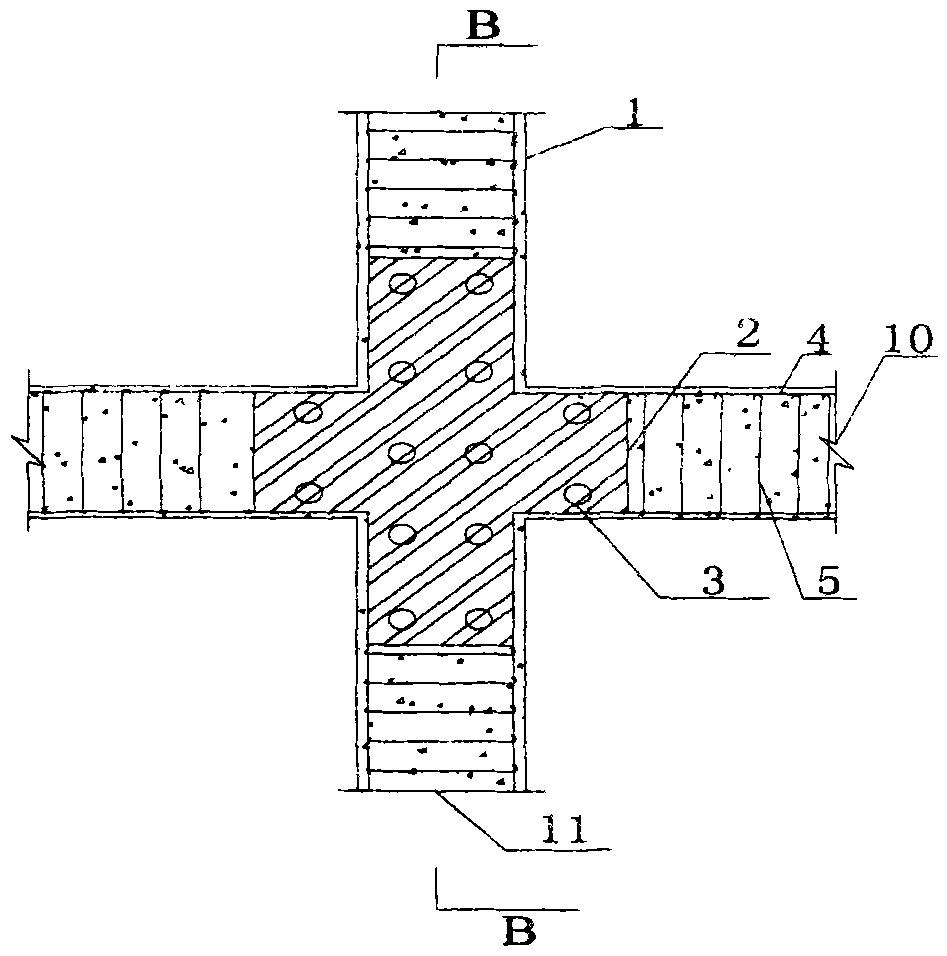

[0035] Embodiment 2 "Schematic diagram of the frame node structure, as can be seen from the figure, it includes beams 10, columns 11, main stressed steel bars 4 and special-shaped steel plates 2 poured in the nodes, and the special-shaped steel plates 2 should be spot-welded with the steel bar skeleton of the node structure connect.

[0036] The thickness of the joint concrete protective layer 1 of the present embodiment is 3cm, and a special-shaped steel plate 2 is respectively arranged on both sides of the joint. A borehole with a diameter of 5 cm has a hollowing rate of about 30% to ensure that the concrete passes through smoothly during the pouring process; transverse stirrups 9 are arranged between the special-shaped steel plates 2 and welded together, and the diameter of the transverse stirrups 9 is 12 mm with a spacing of 8 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com