Printed circuit board transmission band line and electronic equipment

A technology for printed circuit boards and conveyor belts, applied in the directions of printed circuits, printed circuits, printed circuit components, etc., can solve problems such as cracking, reduce the cost and deformation of printed circuit board transmission belt lines, and achieve the effect of reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

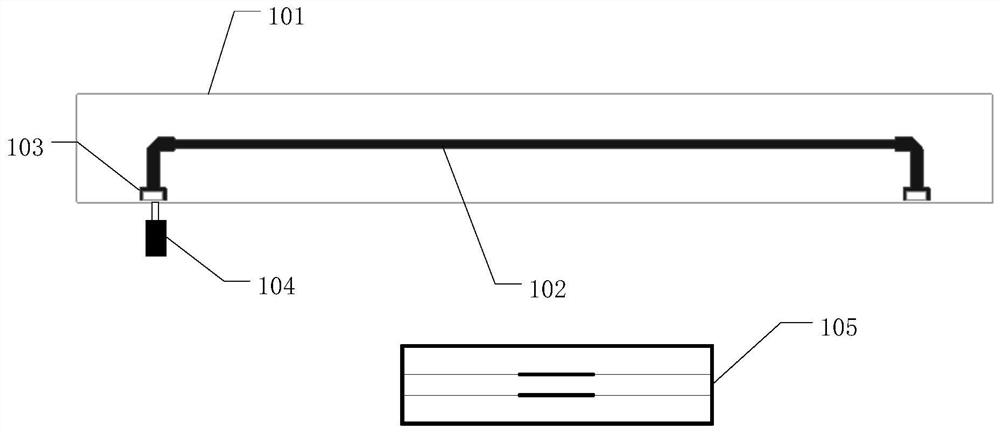

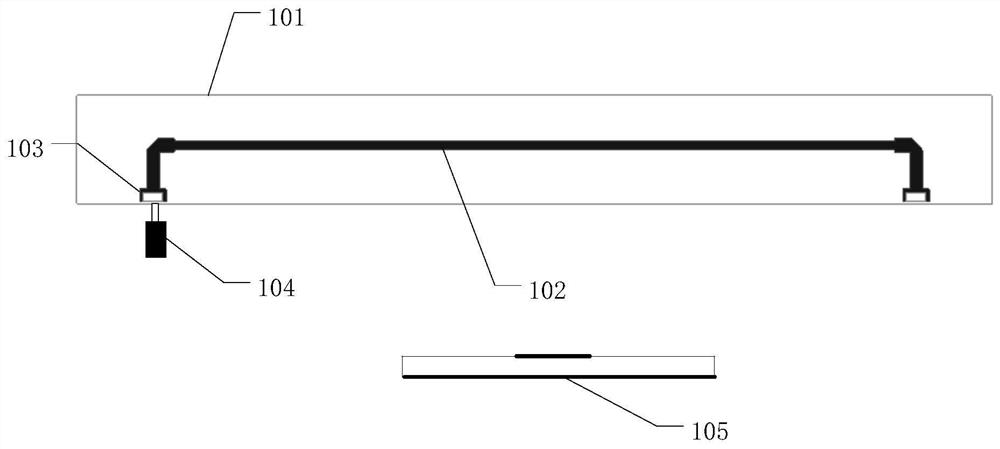

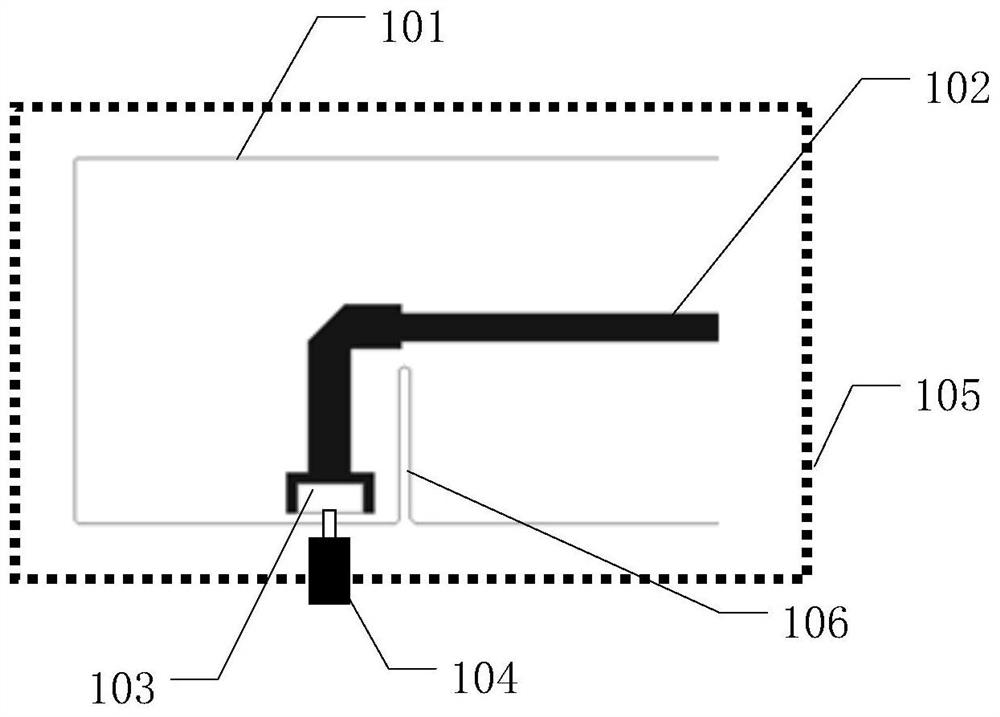

[0027] The embodiment of the present application provides a printed circuit board transmission line and electronic equipment, which is used to provide at least one groove on one side of at least one first welding point of the printed circuit board transmission line, so as to relieve the expansion of metal components. The force acting on the at least one first soldering point, thereby solving the problem of deformation or cracking of the first soldering point in the printed circuit board transmission strip line due to the different thermal expansion coefficients of the materials, without adding an additional material layer, thereby reducing printing. The cost of the circuit board transfer strip line.

[0028] In order to enable those skilled in the art to better understand the solutions of the present invention, the following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the drawings in the embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com