Hand riveter

The technology of pulling riveting guns and pulling rods is applied in the field of pulling riveting guns, which can solve the problems such as the decrease of the gripping ability of the jaws on the pulling rivets, the low work efficiency, and the limited applicable population, and achieves convenient operation, prolongs service life, and expands application. Crowd-wide effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

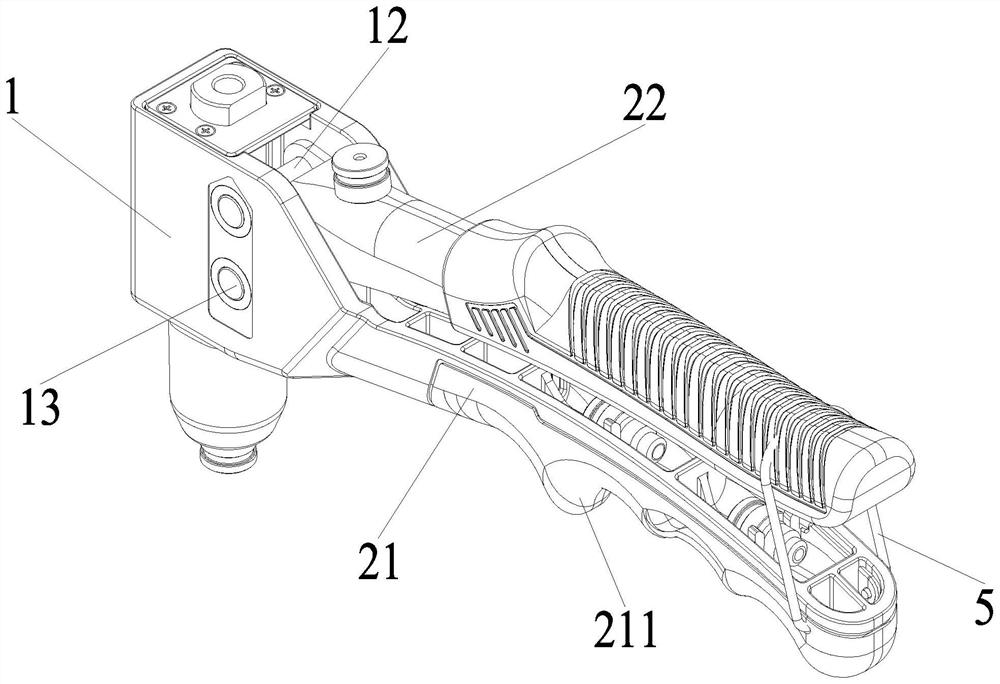

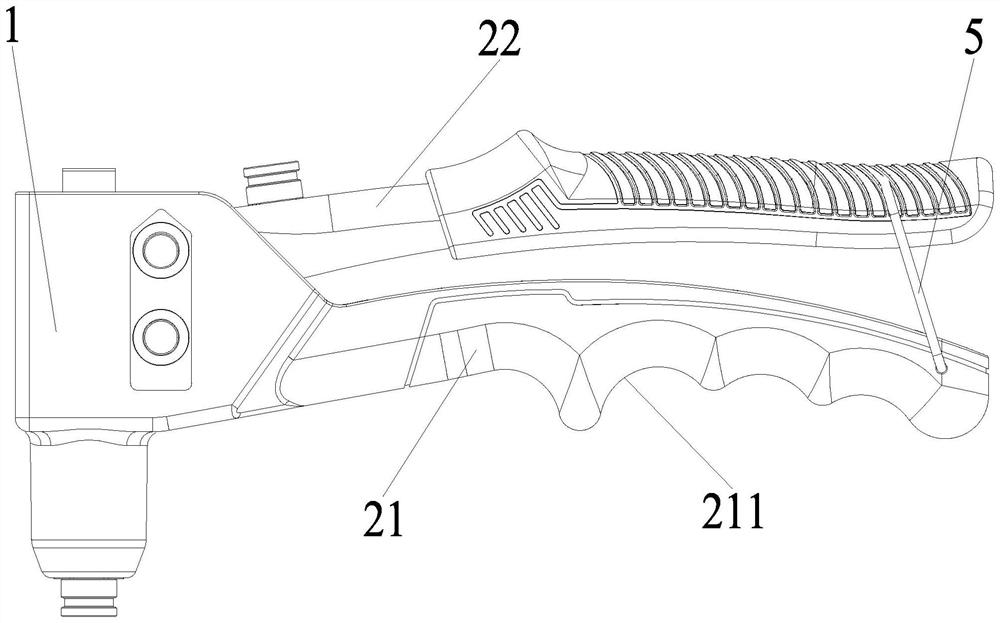

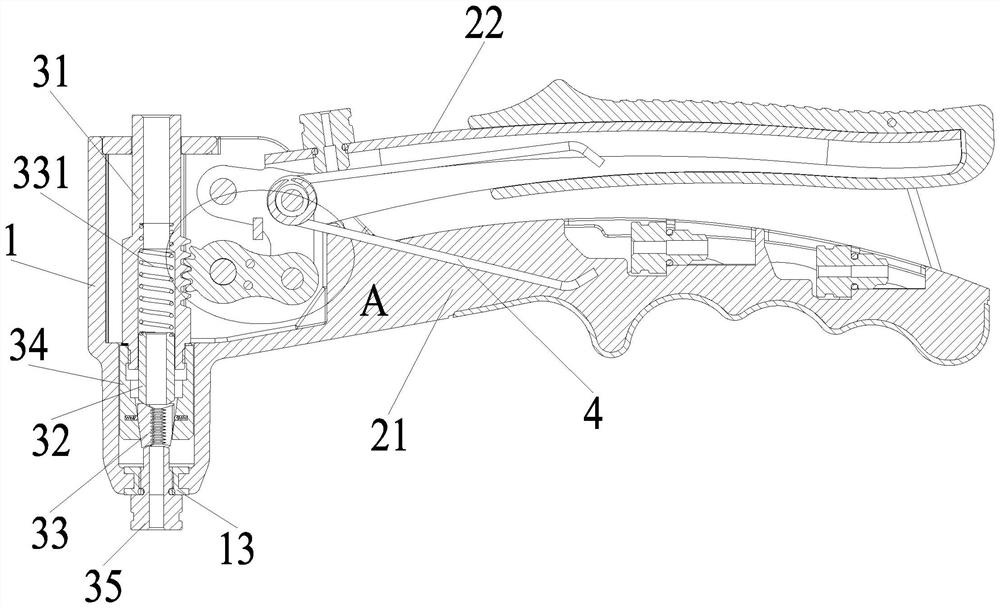

[0033] like Figure 1 to Figure 8 As shown, a pull riveting gun includes a shell 1 with a pull riveting structure built in and a handle, the handle includes a first handle 21 and a second handle 22 that can rotate relatively, the shell 1 and the first handle 21 is a plastic part, the housing 1 and the first handle 21 are integrally formed, and the second handle 22 is connected to the pull riveting structure in a driving manner, and the pull riveting structure is provided with a pressing mechanism. Common riveting guns are made of metal, which are heavy and are not suitable for people with weak strength. In this application, plastics are used to make riveting guns, which can reduce the weight of the finished riveting gun and expand the applicable population of the riveting gun. It can also reduce the production cost of the riveting gun; the genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com