Boat furrow forming device for synchronous furrowing in seeding

A forming device and furrow technology, applied in the field of boat-shaped furrow forming device for synchronously opening furrows during sowing, can solve the problems that the furrow shape is difficult to guarantee, tractor power can not be reasonably used for ditching resistance, etc., and the furrow wall can be smoothed , Good passing performance and consistent groove depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

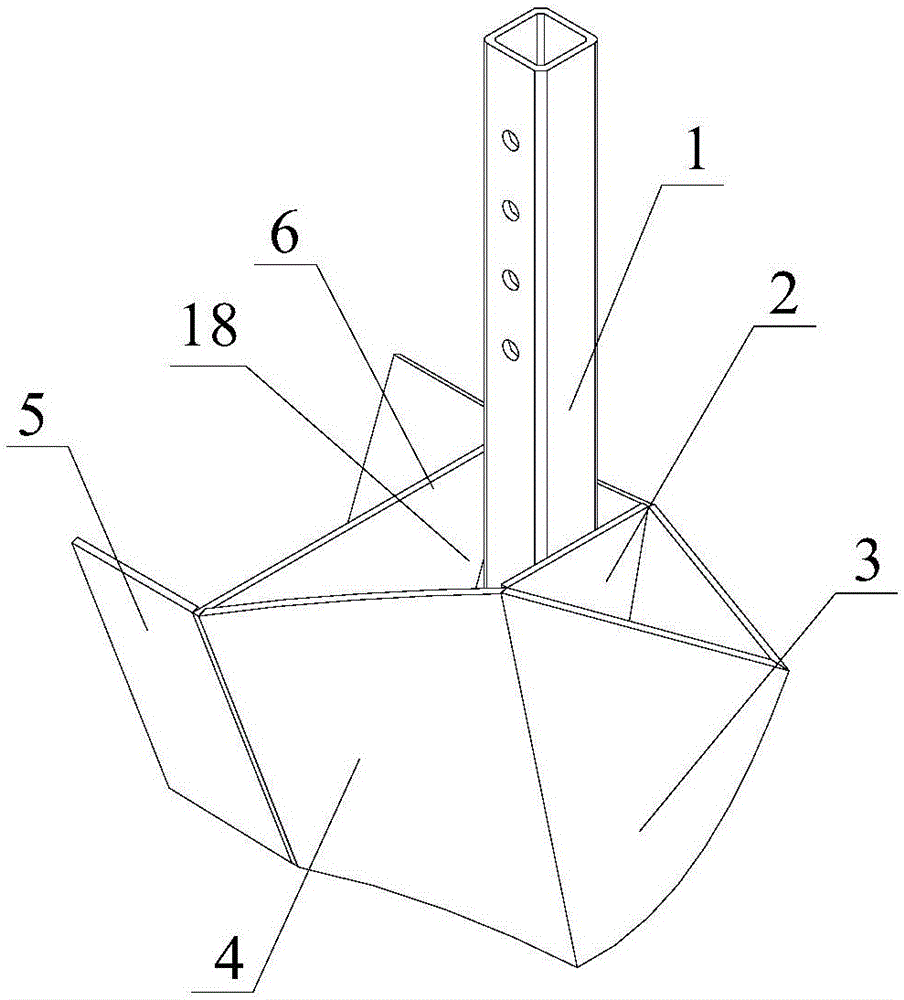

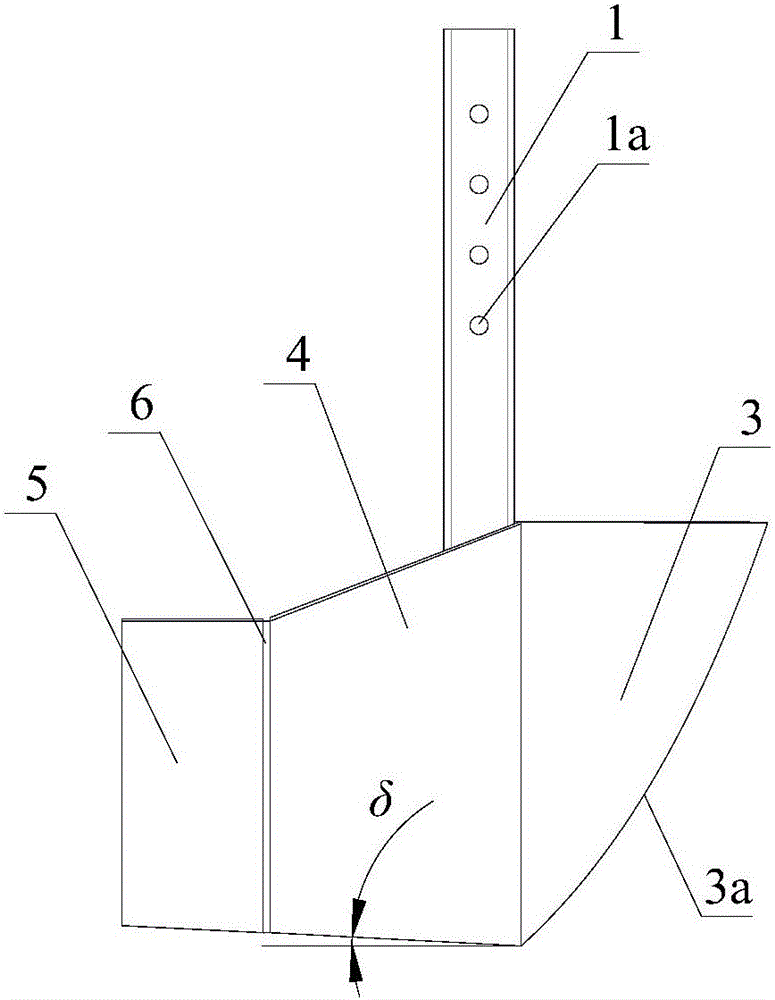

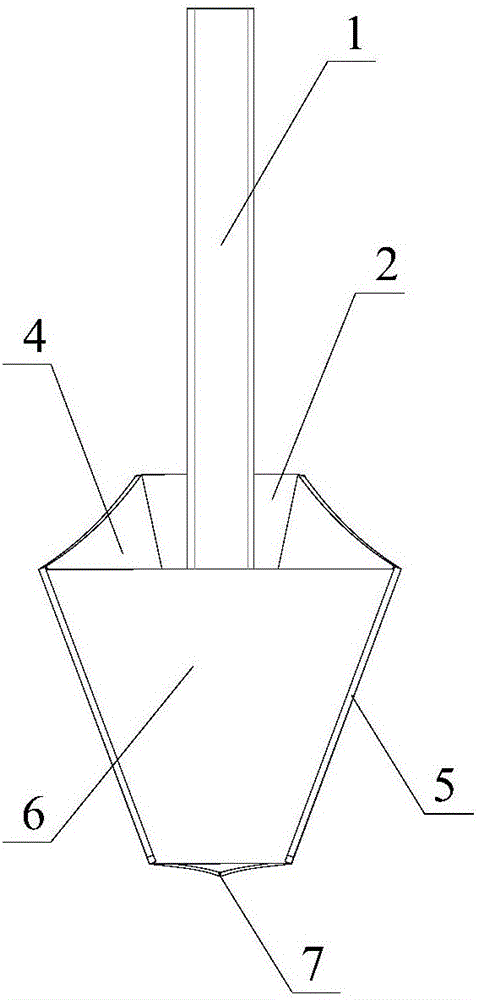

[0033] Such as figure 1 The shown boat-shaped furrow forming device for synchronously opening furrows during sowing includes a pear column 1 and a forming frame body 11 for installing the pear column 1 . combine figure 2 , image 3 As shown, the forming frame body 11 includes two soil-breaking boards 3 of the front part soil-touching module, two shaping boards 4 of the middle part soil-touching module and two flat soil-breaking boards 5 of the rear part soil-touching module, two pieces of soil-breaking boards 3 The curve intersecting the soil-breaking curved surfaces is the edge curve 3a, and the two soil-breaking plates 3, the two shaping plates 4 and the two flat soil plates 5 are arranged symmetrically along the plane where the edge curve 3a is located; the two soil-breaking plates 3 and the two The shaping board 4 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com