Rectangular tunnel full-section blasting excavation construction method

A construction method and technology with a rectangular cross section are applied in the field of tunnel blasting construction to achieve the effect of smoothing the wall surface and improving blasting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

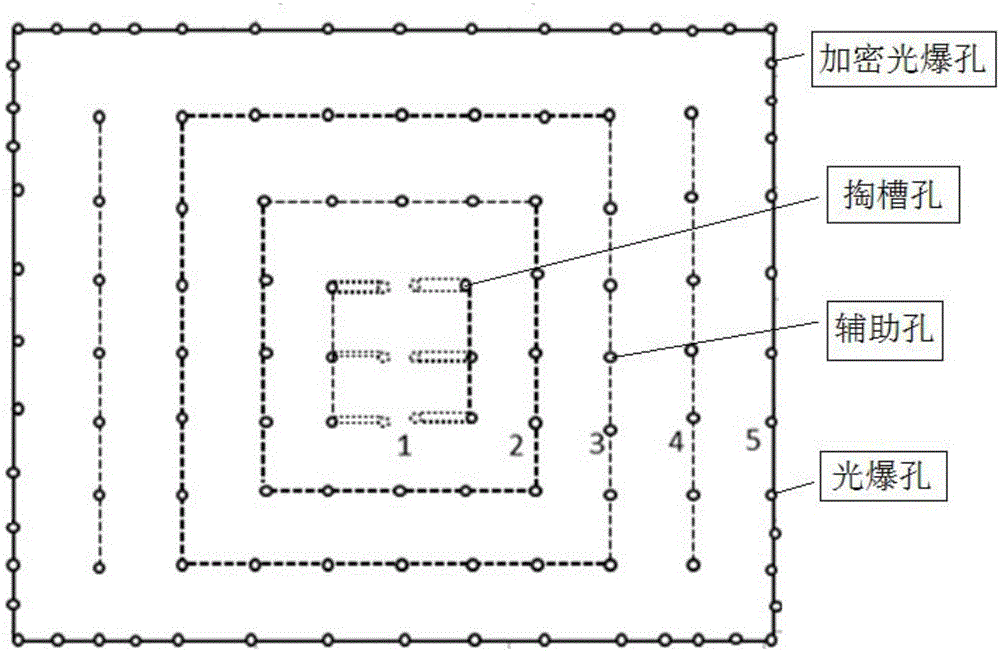

[0069] See attached picture:

[0070] The full-face blasting excavation method of a rectangular tunnel includes the following steps:

[0071] 1) Drilling and blasting design is carried out by using the principle of smooth blasting. Cutting holes, auxiliary holes, light blasting holes and encrypted light blasting holes are arranged in sequence from the inside to the outside, and are blasted one by one according to the requirements of smooth blasting, finally forming a standard design rectangular section;

[0072] 2) Cutting hole: The cutting hole should generally be selected at the weak part of the rock to make full use of the structural plane of the rock in the section; if the rock is homogeneous, when using wedge-shaped cutting, it is generally arranged in the center of the section;

[0073] The inclination angle between the cutting hole and the working surface depends on the hardness of the rock and the cutting form adopted, and generally changes between 55° and 75°;

[0074...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com