Assembled type clean space assembling room and mounting method thereof

A technology of clean space and installation method, applied in building components, walls, buildings, etc., can solve the problems of lack of antibacterial, antibacterial and antivirus functions, serious environmental pollution, and imprecise assembly, etc. Lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

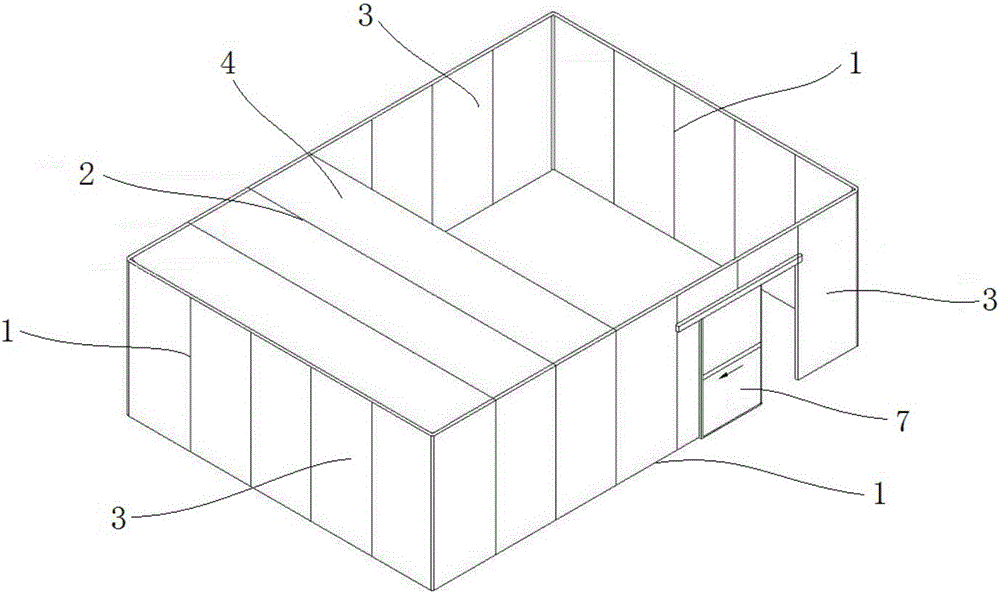

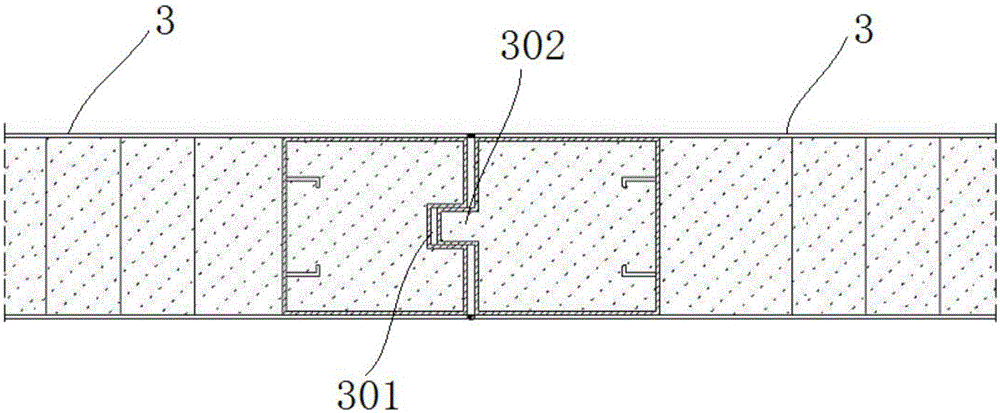

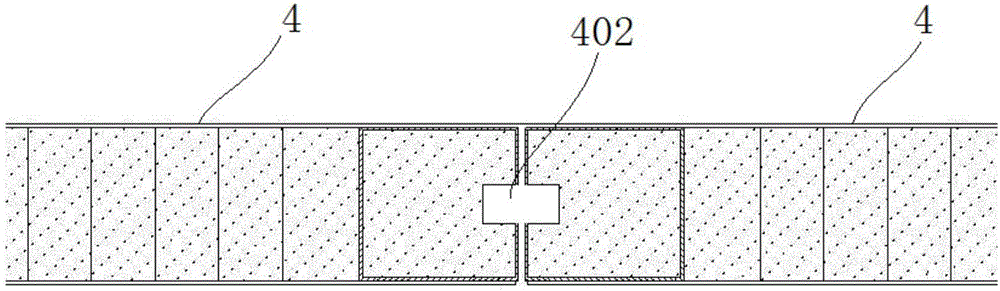

[0046] This embodiment provides an assembled clean space assembly room, such as Figure 1 to Figure 8As shown, it includes a side wall 1, a top 2 and a door 7. The side wall 1 and the top 2 are assembled with wall panels, and the wall panels include a wall panel one 3 and a wall panel two 4. The side wall surface 1 is assembled from several wallboards-3, and the two sides corresponding to the wallboard-3 are provided with convex parts 301 and grooves 302, and the sizes of the convex parts 301 and the grooves 302 match. The two sides of the wallboard 3 are arranged from top to bottom, and the splicing between the wallboards is realized by inserting the convex part 301 into the groove 302; the top surface 2 is assembled from several wallboards 24, so There are grooves 402 on both sides corresponding to the wall panel 2 4, which are arranged from top to bottom on both sides of the wall panel 2 4. The groove 401 and the groove 401 are relatively spliced to form a "middle"-shaped...

Embodiment 2

[0065] This embodiment provides an assembled clean space assembly room, wherein the two sides corresponding to the wall panel 2 4 of the splicing top surface 2 are respectively provided with convex parts and grooves, which are the same as the splicing method of the wall panel 1 3, and several wall panels Two 4 are spliced and assembled by inserting a protrusion between two adjacent wallboards 2 4 into another groove to form the top surface 2 . Others are the same as those described in Embodiment 1, and will not be repeated here.

Embodiment 3

[0067] This embodiment provides an assembled clean space assembly room, such as Figure 10 As shown, the side wall surface is spliced by wallboard one and wallboard two, that is, one side wallboard of the side wall surface is a structure of wallboard two, and the two sides of the wallboard are grooves, so as Figure 11 As shown, the walls on both sides at the right angles where adjacent walls are connected are grooves. The frame body of the wallboard in this embodiment is preferably solid wood. Others are the same as those described in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com