Quickly-clamped building template and concrete pouring device assembled by same

A technology of building formwork and concrete, which is applied to the preparation of building components on site, the connectors of formwork/formwork/work frame, construction, etc. It can solve the problems of rough walls, low connection strength, time-consuming connection and disassembly, etc. Achieve the effect of smooth wall surface, high reuse rate and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

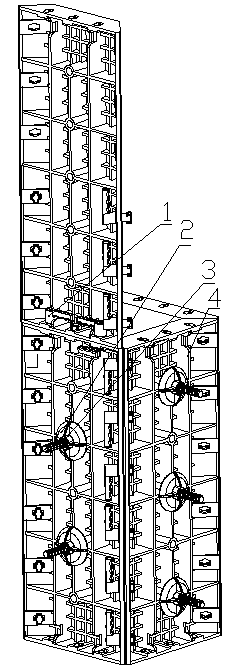

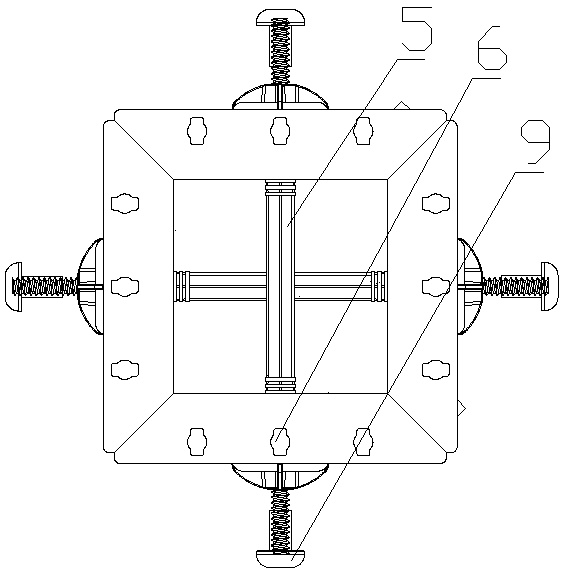

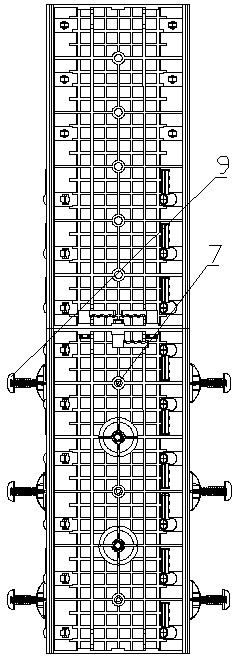

[0022] Such as figure 1 — Figure 4 The concrete pouring device for pouring columns is shown, the building formwork 4 is formed by injection molding of a mixture of 85 parts by weight polypropylene and 15 parts by weight of glass fiber, and the side of the main board of the building formwork 4 facing away from the concrete surface has criss-cross patterns. Reinforcing ribs, wherein the reinforcing ribs on the edge of the main board have at least one waist-shaped through-hole 6, and the middle part of the building template 4 has a tapered through-hole. The sides of the building formwork 4 are 45 degrees, and the upper and lower sides are 90 degrees. The adjacent sides of the four building formworks 4 are locked and connected together by the handle 1 passing through the waist-shaped through hole 6 to form a rectangular pouring device, which is suitable for The square columns are poured. When the height of the concrete pouring device needs to be increased, a corresponding build...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com