High steel level petroleum casing pipe and oil pipe manufacturing process

A technology for oil casing and manufacturing process, applied in the direction of manufacturing tools, casings, drill pipes, etc., can solve the problems of large variation in the length of the finished pipe, low market matching, and low precision of the wall thickness of the seamless pipe. Low cost, easy to size, uniform wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the drawings and its specific implementation.

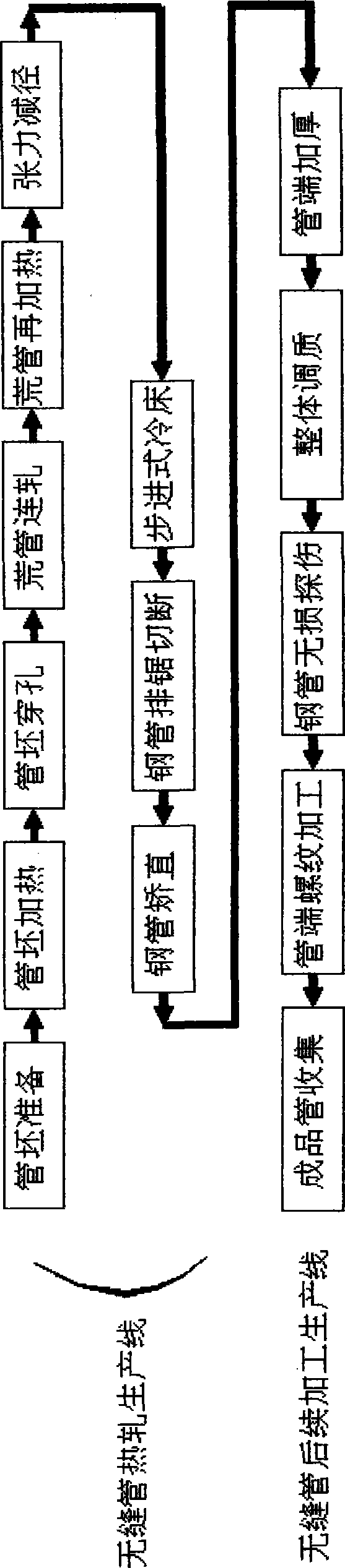

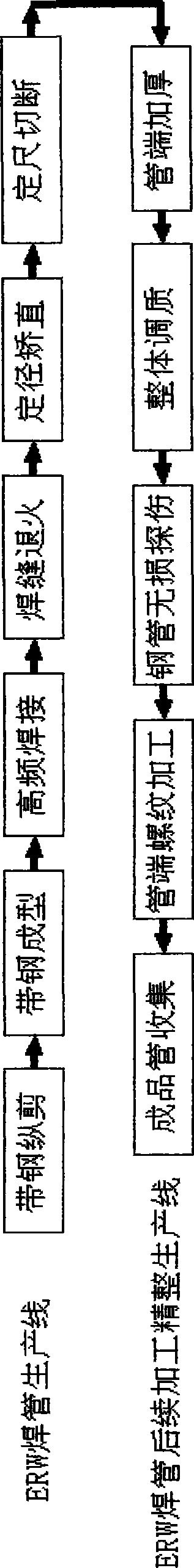

[0015] Such as figure 1 As shown, the entire steel pipe production process includes the following parts: slitting production line, ERW welded pipe production line, pipe end thickening production line, steel pipe quenching and tempering production line, and pipe processing production line.

[0016] Among them, the raw material of the slitting production line is the hot rolled coil produced by a regular large-scale steel enterprise. The composition of the steel pipe is very strict, especially the content control of harmful elements. Although the requirements for P and S in the API 5CT standard are not high, ≤0.03 % Is sufficient, but in actual production, the control of P and S is very strict, and the requirements are: P≤0.01%, S≤0.008%. And there are certain requirements for the shape of inclusions. Generally, there is refining outside the furnace in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com