Steel slag asphalt concrete with good anti-rutting performance and preparation method thereof

A steel slag asphalt and anti-rutting technology, applied in the field of asphalt concrete, can solve the problems of unsatisfactory anti-rutting performance, achieve the effects of improving anti-rutting performance, improving viscosity, and avoiding reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A method for preparing steel slag asphalt concrete with good anti-rutting performance, comprising the following steps:

[0034] S1. Steel slag treatment: put the steel slag into the screening equipment for screening, and screen out impurities such as metal substances and tiles in the steel slag;

[0035] S2. Coarse aggregate preparation: Add steel slag and limestone gravel processed in S1 to the crushing equipment in proportion, and crush the steel slag and limestone gravel into a particle size of 2.15-13.5mm through the crushing equipment. After the crushing is completed, mix The material is transferred to the drying equipment for drying, and finally the coarse aggregate is obtained;

[0036] S3. Mixing preparation: import the coarse aggregate and fine aggregate, cement, filler and phase change material prepared in S2 into the mixing device, fully and uniformly mix each raw material, obtain the mixed material after the mixing is completed, and then take it out for use;...

no. 1 example 1

[0051] Based on the first embodiment of the present invention, a method for preparing steel slag asphalt concrete with good rutting resistance, the second embodiment of the present invention provides another method for preparing steel slag asphalt concrete with good rutting resistance, wherein the second embodiment Examples will not hinder the independent implementation of the technical solution of the first embodiment.

[0052] Specifically, the present invention provides another method for preparing steel slag asphalt concrete with good anti-rutting performance. The difference lies in:

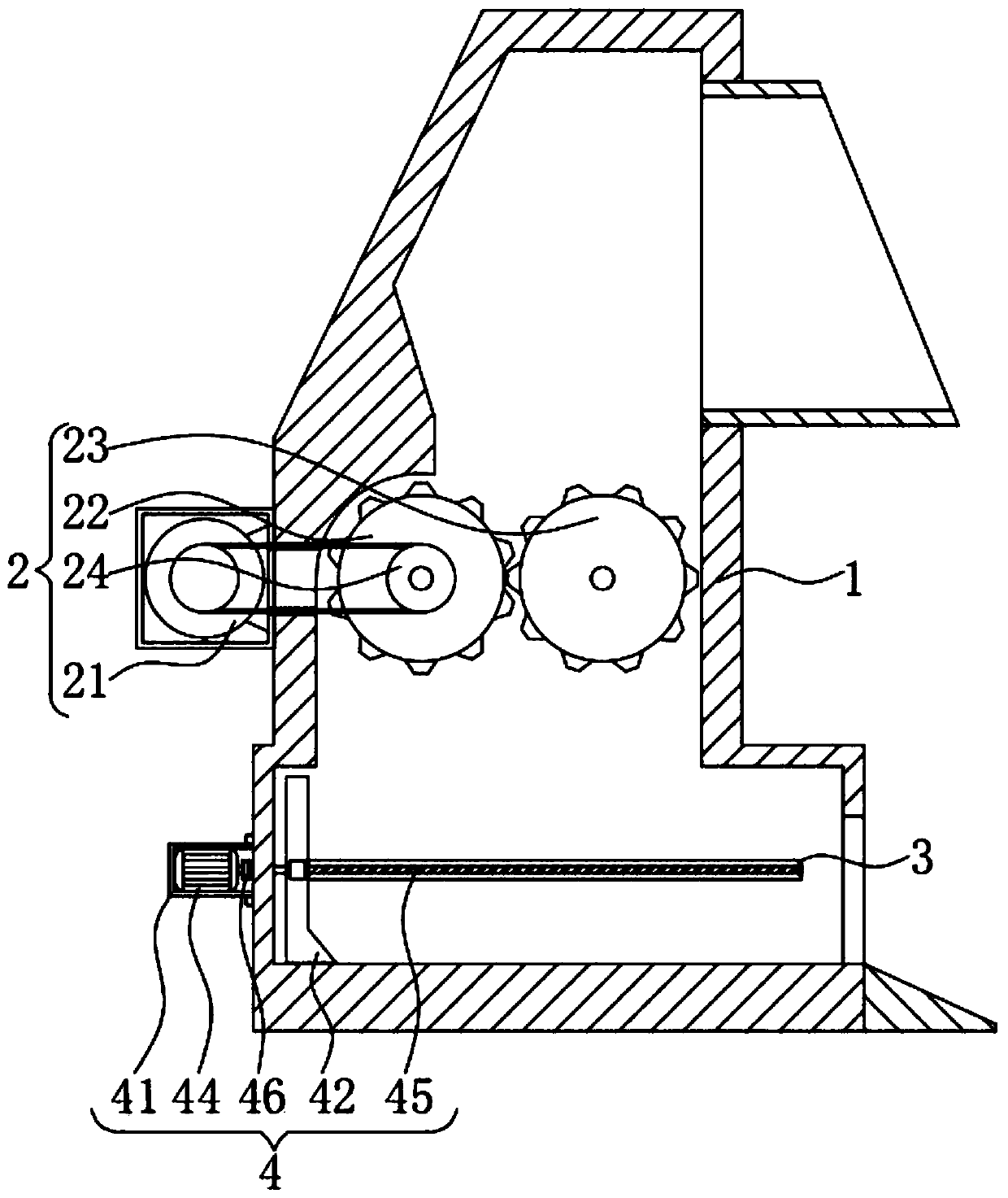

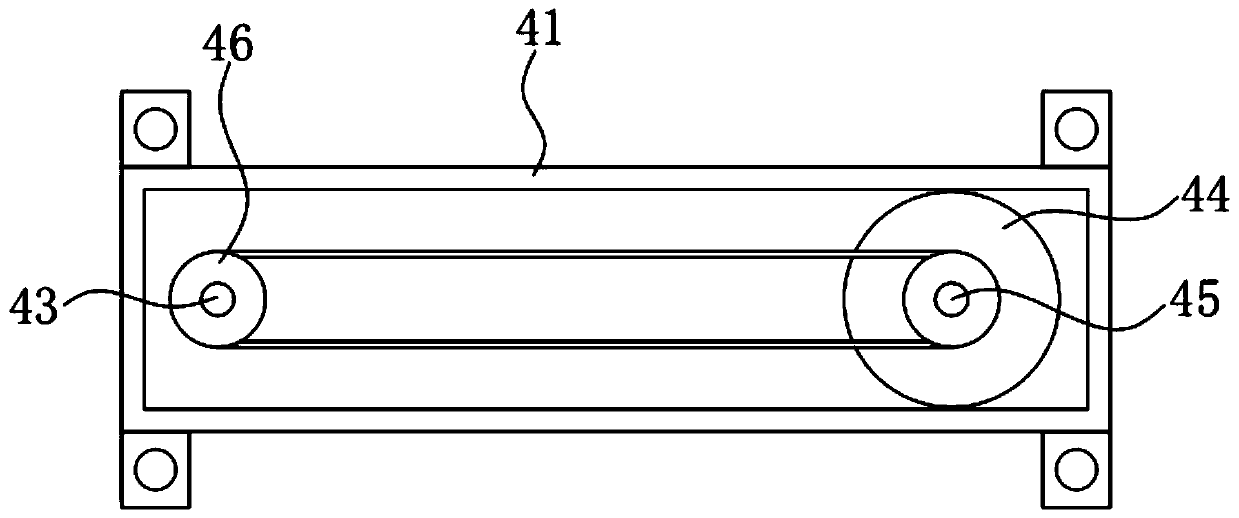

[0053] It is used to crush steel slag and limestone gravel in S2. The crushing equipment includes a body 1, and a crushing structure 2 is arranged inside the body 1. The crushing structure 2 includes a rotating motor 21, a first crushing roller 22 and a second crushing roller. Two crushing rollers 23, one end of the output shaft of the rotating motor 21 and the second crushing roller 23 are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com