Wallboard for building

A technology of buildings and wall panels, which is applied in the direction of building structures, buildings, building components, etc., can solve the problems of high strength, long production cycle, frame damage, etc., achieve the requirements of reducing load-bearing strength, and install conveniently, quickly, accurately and quickly The effect of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

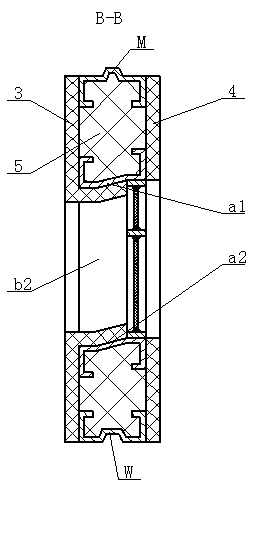

[0033] Example 1: the basic implementation of the wallboard of the present invention comprises the frame 1 that four metal profiles form up and down, left and right, the cross-sectional shape of the metal profiles includes special-shaped protrusions and special-shaped grooves, foam concrete is filled in the frame 1, and one side of the frame 1 is connected to the The interior trim panel 4 is connected, and the other side is connected with the exterior trim panel 3 .

example 2

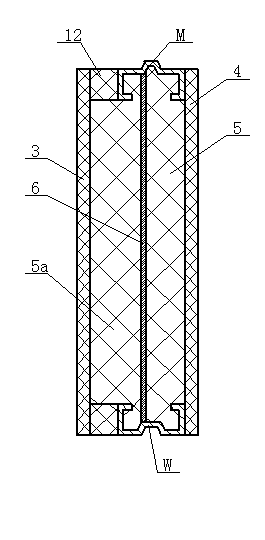

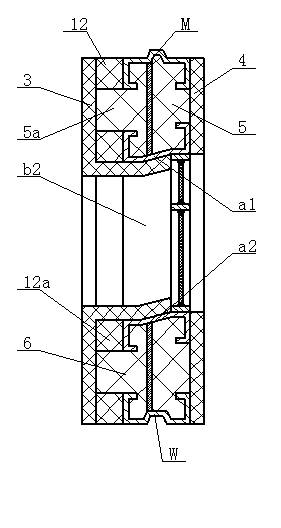

[0034] Example 2: In order to further improve the supporting strength and rigidity of the wallboard, a metal mesh 6 is added on the basis of the structure of the embodiment 1, that is, the metal mesh 6 is installed in the frame 1 and connected with the frame 1 respectively. The metal mesh 6 can be made of metal wires, metal columns, or steel plates with holes. The foamed concrete filled in the frame 1 fully contains the metal mesh 6, so that the metal mesh 6 plays a supporting role in the foamed concrete, and further improves the impact resistance of the wallboard.

example 3

[0035] Example 3: If Figure 5 , Figure 6 , Figure 10 As shown, on the basis of the structure of embodiment 2, the wallboard of the present invention adds the structure of heat insulation pad 12, that is: install heat insulation pad 12 between exterior trim panel 3 and special-shaped protrusions and special-shaped grooves; The pad 12 can also be installed between the exterior trim panel 3 and the first metal profile a1, the second metal profile a2, the third metal profile b1 and the fourth metal profile b2; the heat insulation pad 12 can also be installed between the exterior trim panel 3 and the special-shaped convex Between the rise, the special-shaped groove, the first metal profile a1, the second metal profile a2, the third metal profile b1 and the fourth metal profile b2. This structure can prevent the hot and cold temperatures on the exterior panel 3 from being directly transferred to the metal profile, further improve the heat insulation and heat preservation perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com