Underground pipe embedding construction method

A construction method and technology for underground pipes, which are applied in the sewer system, waterway system, water supply device, etc., can solve the problems of anti-floating, instability, water seepage and leakage of the pipe body interface, etc., and achieve stable and reliable quality and simple construction process. , On-site production of convenient and fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

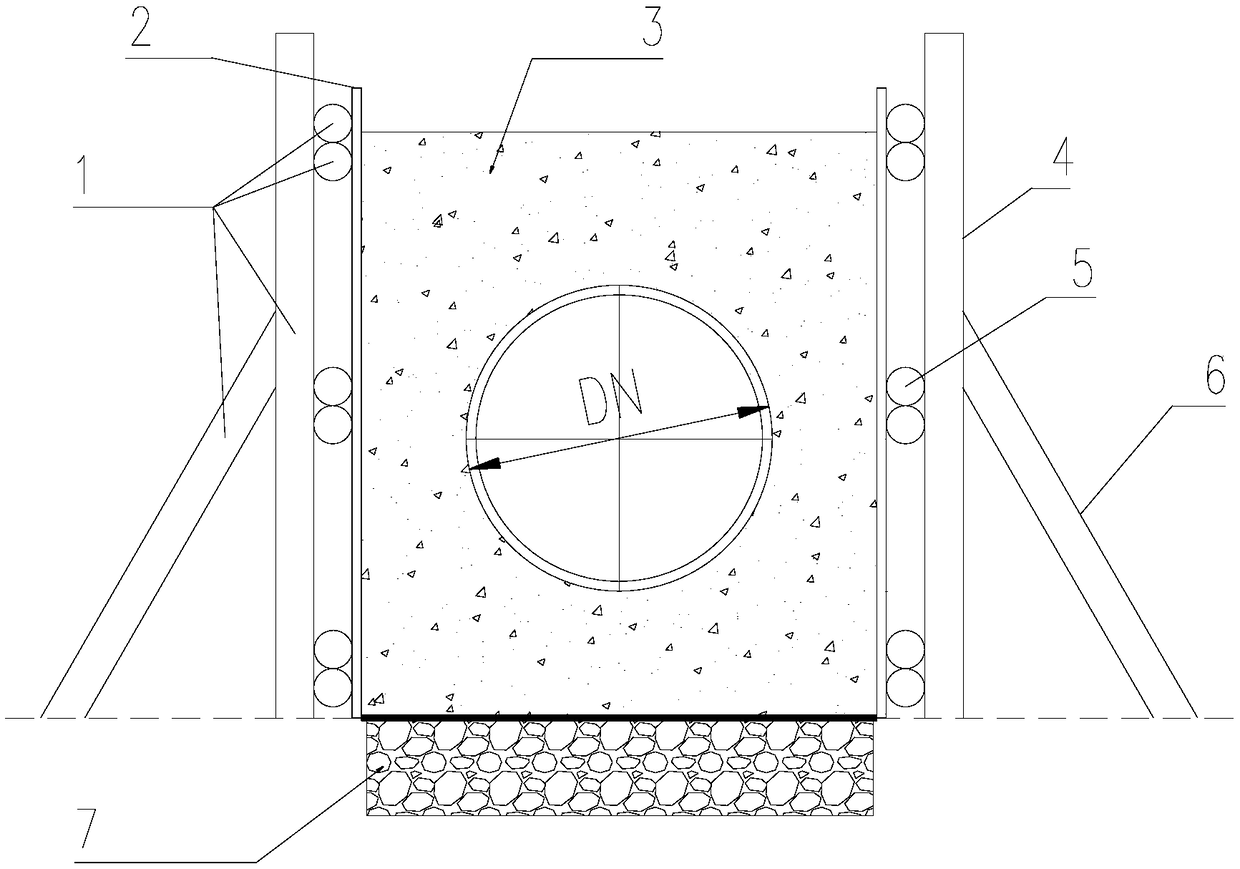

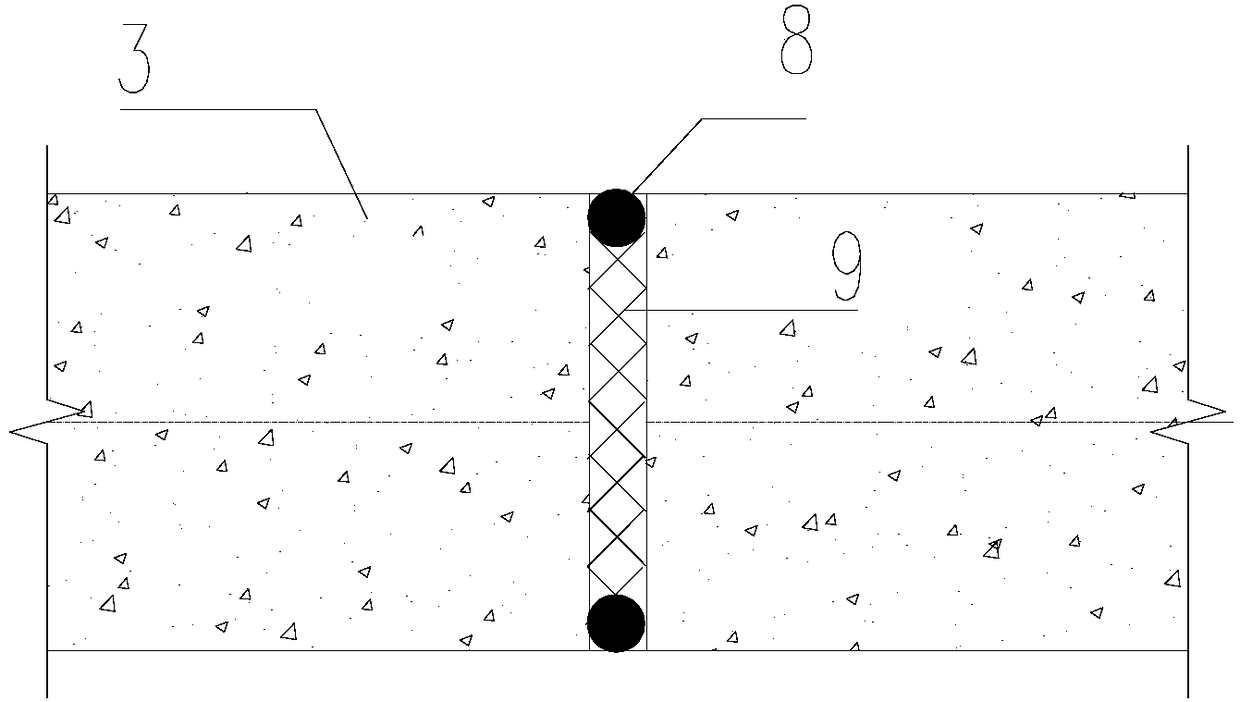

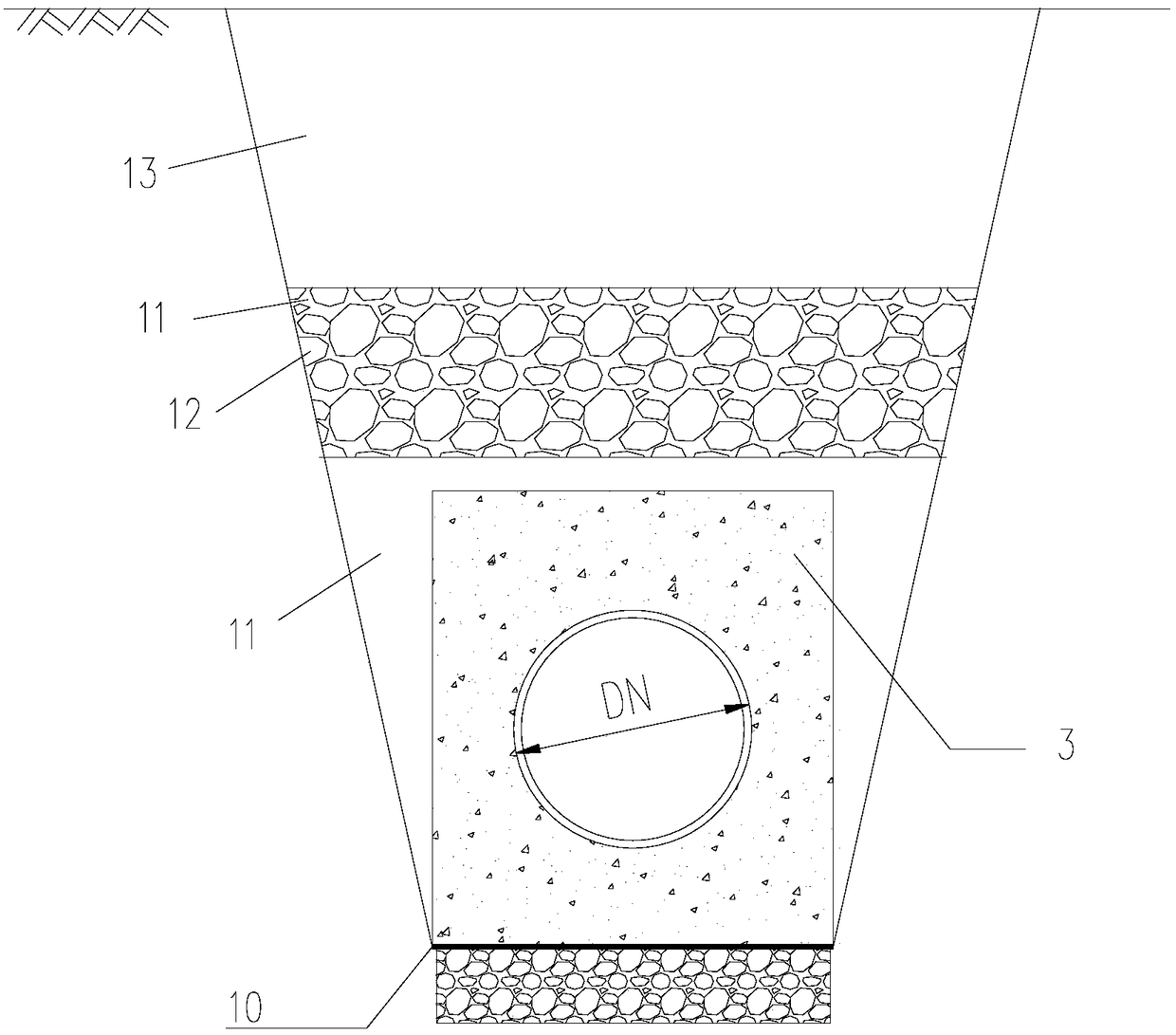

[0030] For the construction method of underground pipe body guarantee, please refer to figure 1 , figure 2 , image 3 , including the following steps:

[0031] 1) Pipe trench excavation

[0032] According to the design height of the trench, slope excavation is adopted, and each side of the trench excavation line should be increased by 500mm; among them, the trench base after the excavation of the pipeline trench is a round gravel layer or sandstone layer, if the trench The base 7 is a filling soil layer, and the filling soil layer is replaced with sand and gravel to the round gravel layer or sandstone layer; wherein, the compaction coefficient of sand and gravel replacement is not less than 0.97;

[0033] 2) Cushion foundation construction

[0034] Concrete is used to pour the cushion 10, the concrete compressive strength grade used is C20, and the pouring thickness of the cushion 10 is 10cm. When pouring the cushion 10, rings for fixing the pipeline are pre-buried every ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com