Cast-in-place section concrete construction method of assembling-type concrete structure

A concrete structure and concrete technology, which is applied in the construction of buildings, construction, and building materials processing, etc., can solve the problems of cracking and deformation of the protective layer, strengthen the lateral compressive strength, reduce the amount of repair work, avoid cracking and other problems. deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the examples, and the purpose is only to better understand the content of the present invention. Therefore, the examples given do not limit the protection scope of the present invention.

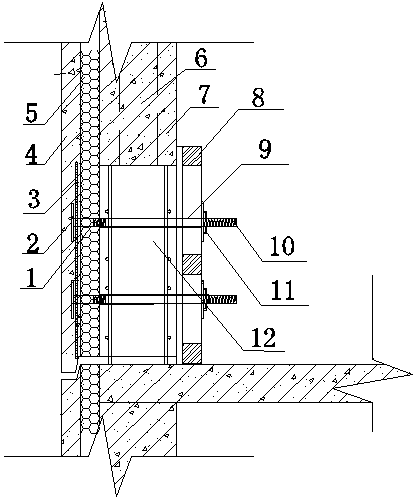

[0015] see figure 1 , figure 2 , the concrete construction method of the cast-in-place section of the prefabricated concrete structure given in this embodiment is carried out according to the following steps:

[0016] (1) Embedded parts are buried in the protective layer 4 and steel mesh 3 is added.

[0017] In the production process of the prefabricated exterior wall, embedded parts are embedded in the exterior wall protection layer 4 corresponding to the cast-in-place section 12 and steel mesh 3 is added. The sleeve 2 is composed of the embedded plate 1, which is a 150mm*150mm*6mm steel plate, which is pre-embedded at a distance of 25mm from the outer surface of the protective layer 4 and located outside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com