Crank type underwater robot ejection device

An underwater robot and ejection device technology, which is applied to underwater operation equipment, transportation and packaging, ships, etc., can solve the problems of fixed range, difficult waterproofing, complex structure, etc., and achieve the effect of strengthening mutual cooperation and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

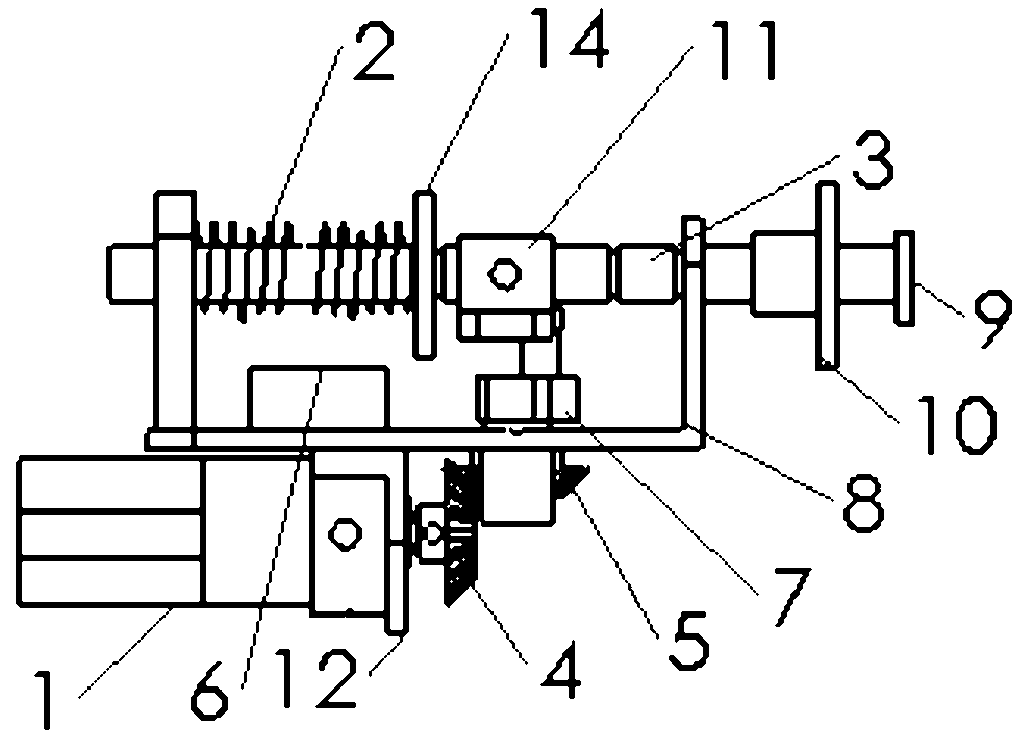

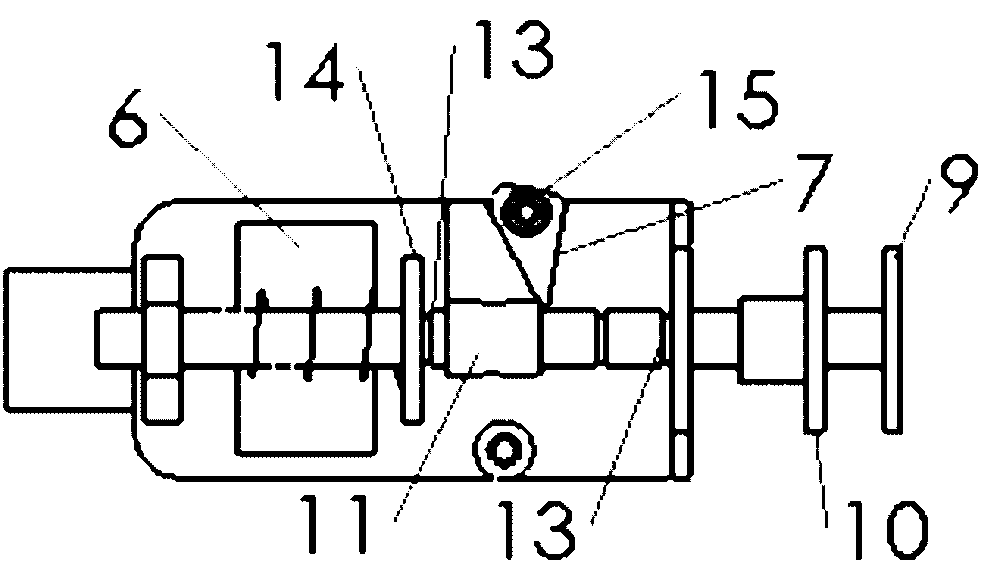

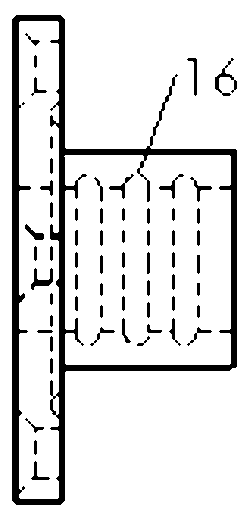

[0018] as attached figure 1 , attached figure 2 As shown, the device is installed on the inner wall of the underwater robot cavity and can be controlled by the core board system (control board) of the underwater robot. board to determine the current status. If it is in the disconnected state, the control board sends instructions to the motor 1 to make it rotate until the limiter switch is closed, and the state at this time is called the initial position. If it is in the closed state, then keep the current state and wait for the instruction.

[0019] When the device was in the initial position, that is, when the limiter 6 switch was in the closed state, the crank 7 was in the limit position. The control board sends ejection commands to the motor 1 according to the task requirements. The rotation of the motor 1 drives the bevel gear 4, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com