Novel prefabricated concrete hollow slab girder and construction process for building roads and bridges by using same

A hollow slab girder and concrete technology, which is used in the erection/assembly of bridges, bridge construction, joists, etc., can solve the problem of difficulty in better improving the accuracy of wedge-shaped backing plates, increasing design, construction workload, and prolonging design and construction periods, etc. problems, to shorten the design cycle, improve strength, and eliminate shear slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

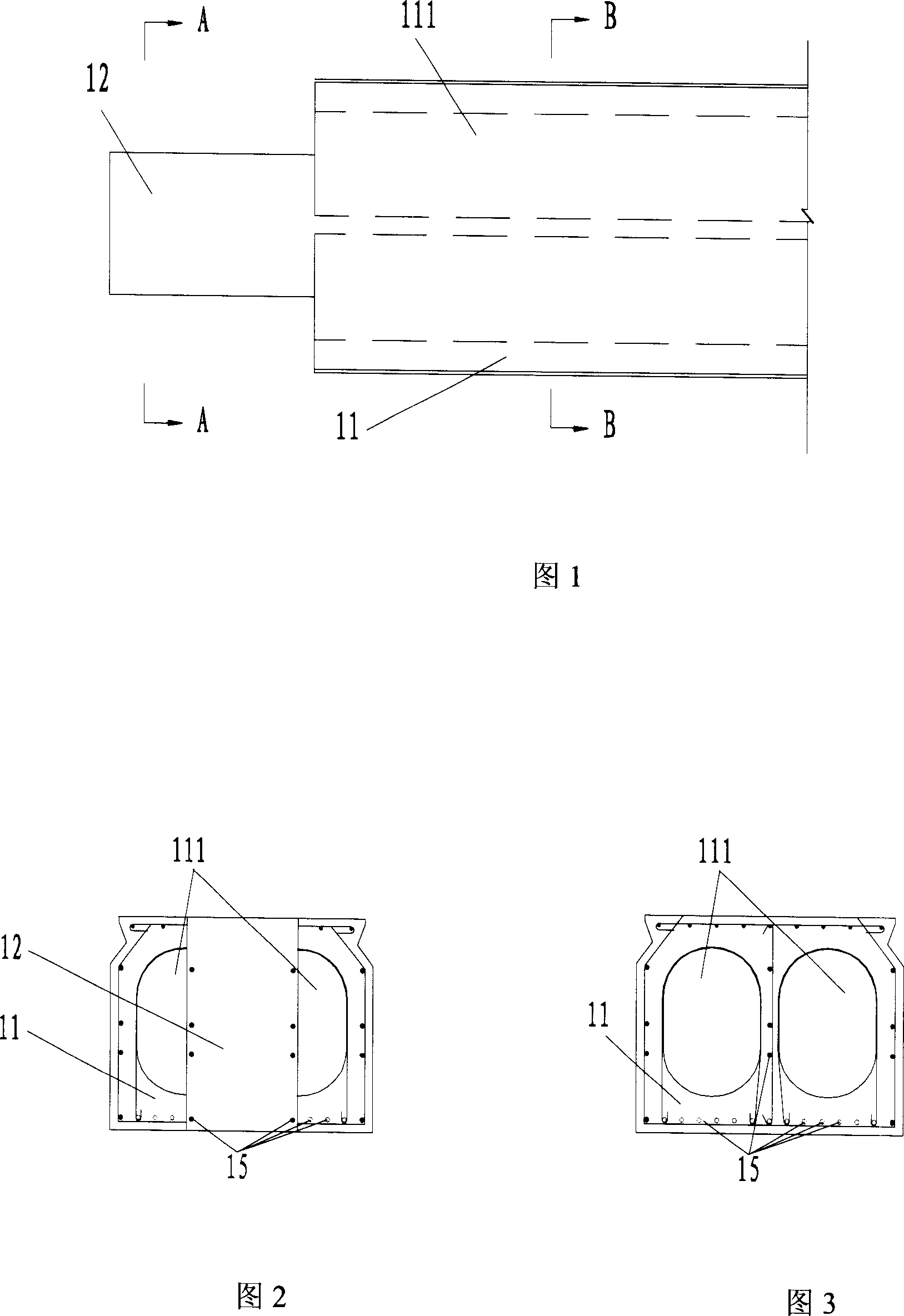

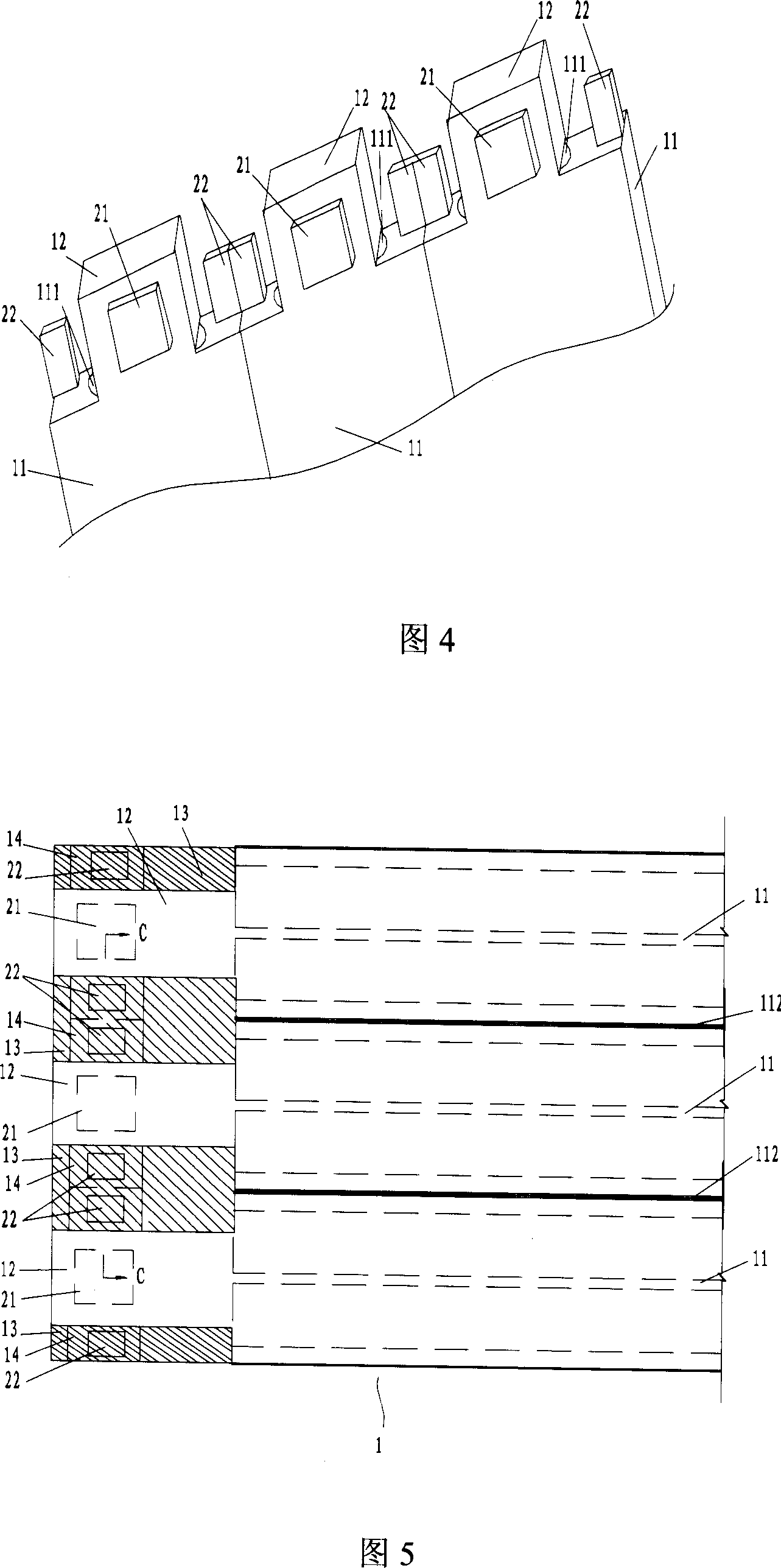

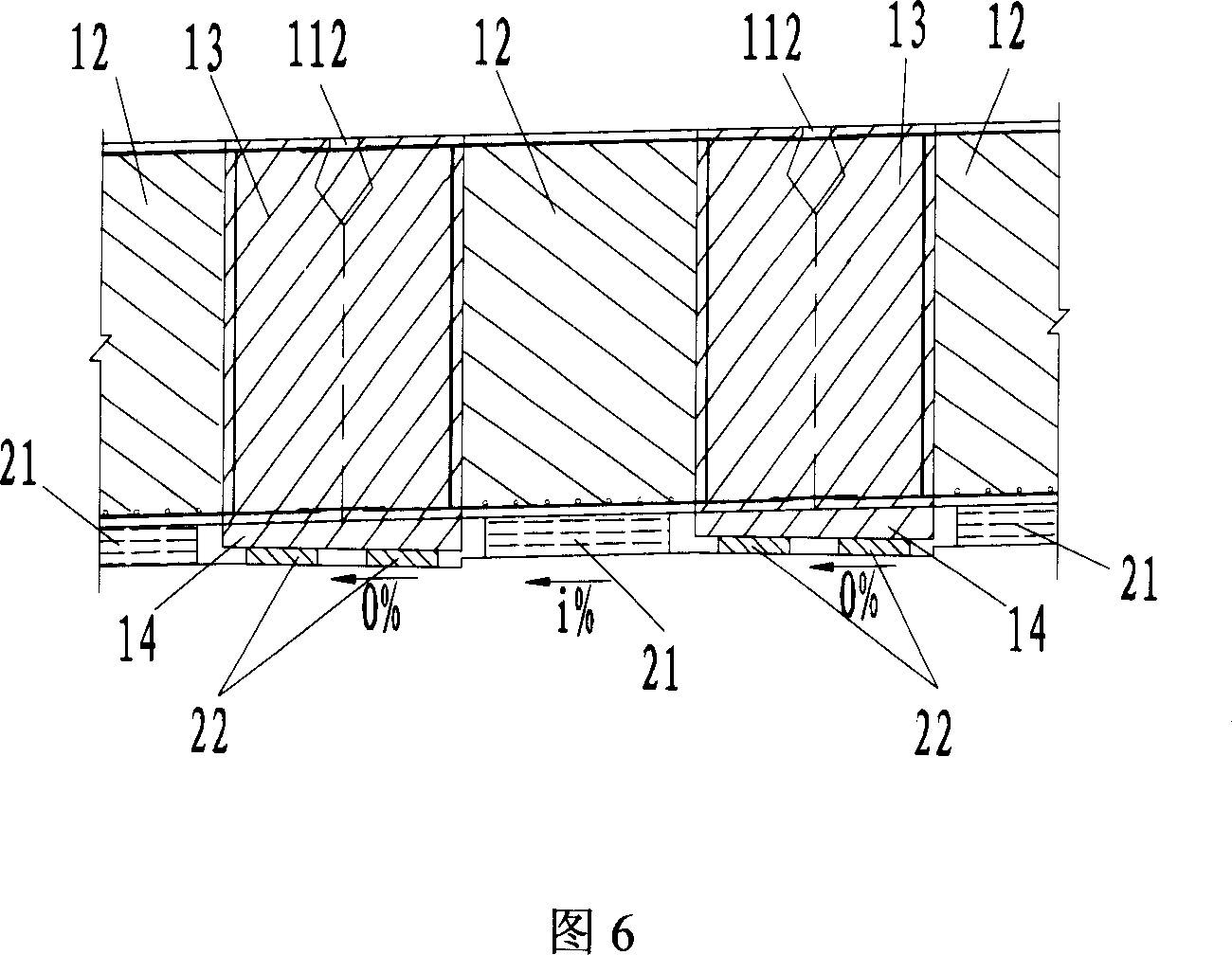

[0037] As shown in Figure 1, it is a specific embodiment of the novel prestressed concrete hollow slab girder of the present invention, the material of the hollow slab girder is prestressed reinforced concrete, comprises a quadrangular body 11, and the top surface of the body 11 is roughly smooth, and There is a through cavity 111 inside, and the two ends 12 respectively located at the two ends of the body 11, the two ends 12 and the body 11 are integrally formed, and the prestressed steel bars are pre-embedded continuously in the body 11 and the two ends 12 15. Since the shapes and forces of the two ends 12 in this embodiment are symmetrically the same, only the ends 12 will be described below.

[0038] As shown in Fig. 1, Fig. 2 and Fig. 3, the end 12 is tenon-shaped, protrudes about 1 meter from the body, and is a solid body, and its top and bottom surfaces are flush with the top and bottom surfaces of the body 11. The width of the end 12 is slightly less than half of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com