Method for testing permeability resistance of concrete

A technology of impermeability test and concrete, which is applied in the preparation of test samples, permeability/surface area analysis, measuring devices, etc. It can solve the problems of time-consuming, complicated process, water seepage of test block and test mold, etc., and achieve cost reduction, Good sealing effect and effect of improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

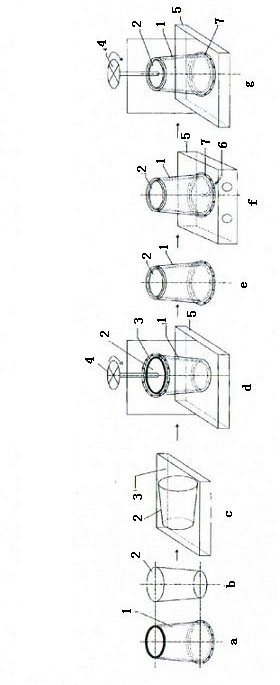

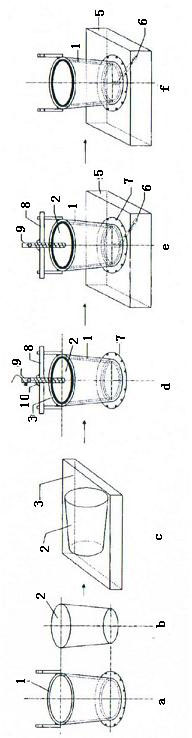

[0014] 1. Heat the test mold 1 for the concrete impermeability test to 65-70°C in an oven.

[0015] 2. Roll the hot wax 3 onto the periphery of the test piece 2.

[0016] 3. Quickly put the wax-coated test block into the test mold, the top diameter of the test mold is larger than the bottom diameter.

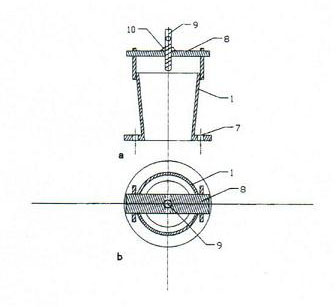

[0017] 4. Tighten the top pressure devices 8 and 9 (tighten the nut 10 with a wrench) to press the test block into the test mold, and implement a wax seal between the test block and the test mold.

[0018] 5. Fix the test mold with the test block 2 on the tester platform 5 with the bolt 7 .

[0019] 6. Open the pressure water valve 6 to pressurize the test block and do the impermeability test.

[0020] 7. After the test is completed, keep the pressure water pressure constant, loosen the nut 10 of the top pressure device with a wrench, and the test block is pushed out from the test mold by the pressure water top.

[0021] 8. Close the pressure water valve, remove the fixing bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com