Composite type self-adhesion water stop band, manufacturing method and construction method

A waterstop, composite technology, applied in water conservancy projects, belts, marine engineering and other directions, can solve problems such as deformation and tearing of waterstops, leakage and water seepage at the connection between waterstops and concrete, and prevent buildings Leakage, long-lasting adhesion and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

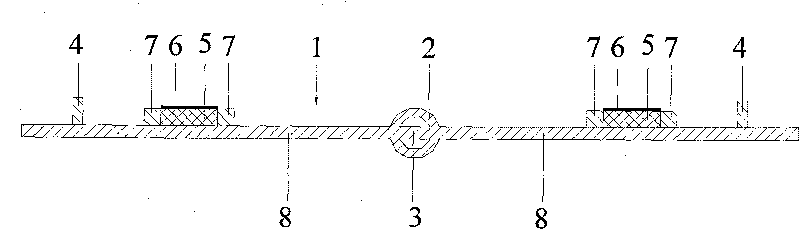

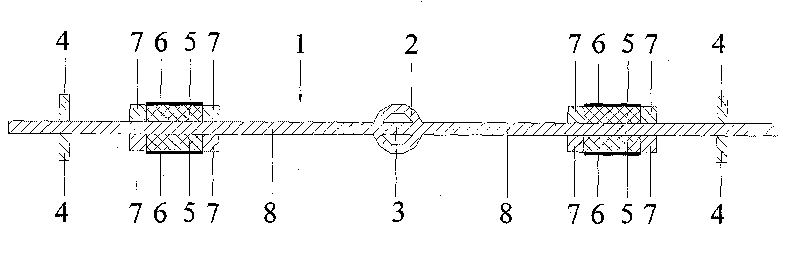

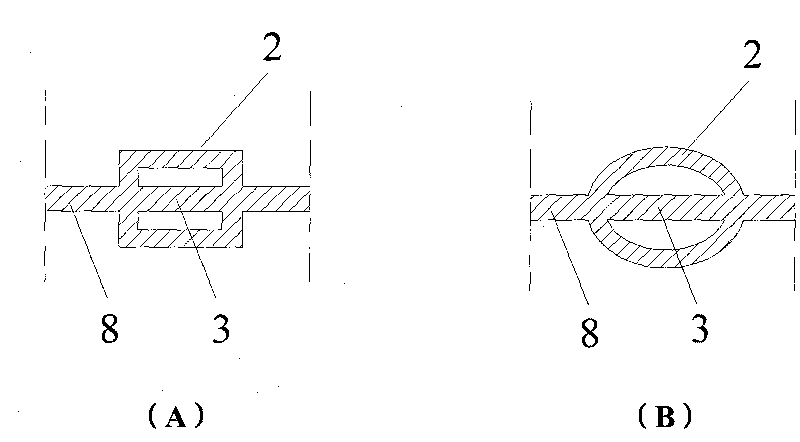

[0039] The main body of the waterstop base material (1) is a profile as a whole, and the main body of the waterstop base material (1) is composed of a telescopic hole (2), a telescopic belt (3), a waterstop base plate (8), a concave bonding groove (7 ) and water-stop ribs (4), the middle part of the main body (1) of the water-stop strip is provided with a telescopic hole (2), the telescopic hole (2) is hollow as a whole, and the cross-sectional shape of the telescopic hole (2) is circular or elliptical shape or rectangle, the middle part of the telescopic hole (2) is provided with a telescopic band (3), the telescopic band (3) runs through the telescopic hole (2) through the middle part of the telescopic hole (2), and the telescopic band (3) keeps the telescopic hole (2) According to the cross-sectional shape, the creep of concrete (9) or geological change causes the dislocation to tear the telescopic belt (3), and the deformation of the telescopic hole (2) still maintains the ...

Embodiment 2

[0044] The main body of the waterstop substrate (1) is made of water-soluble polyurethane prepolymer or sodium acrylate polymer water-absorbent resin or rubber or plastic or neoprene material, and is made into the main body of the waterstop substrate through an extrusion molding machine (1) Profile, during the extrusion molding process, a telescopic hole (2) is made in the middle of the main body (1) of the waterstop substrate, the telescopic hole (2) is hollow, and the cross-sectional shape of the telescopic hole (2) is circular or oval or Rectangular, the middle part in telescopic hole (2) makes telescopic band (3), and telescopic band (3) runs through telescopic hole (2) by the middle part of telescopic hole (2).

[0045] The two ends of the main body of the waterstop substrate (1) are made along the two sides of the telescopic hole (2) to form a correspondingly flat waterstop substrate (8), and the two ends of the main body of the waterstop substrate (1) are The water belt...

Embodiment 3

[0050] First, take out the rolled waterstop base material body (1), remove the outer packaging, and fix the waterstop base material body (1) along the deformation joint of the concrete building to the deformation joint of the concrete building to be poured according to the design requirements Above, the center line of the telescopic hole (2) of the base material body (1) of the waterstop is aligned with the centerline of the deformation joint of the concrete building, and the telescopic belt (3) in the telescopic hole (2) maintains the cross-section of the telescopic hole (2) Shape, the both sides of waterstop base material main body (1) are fixed with mould, when waterstop base material main body (1) is positioned, waterstop base material main body (1) can not turn over, twist phenomenon.

[0051] Before pouring concrete (9), remove the isolation layer (6) on the bonding layer (5) in the concave bonding groove (7), check the fixation of the main body (1) of the waterstop, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com