Rolling bearing root part for support hanger

A technology of rolling bearings and hangers, which is applied in the direction of pipeline supports, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problem of not meeting the monitoring requirements of support and hanger systems, affecting the normal operation of piping systems and equipment, and failing to fully reflect Thermal expansion and other issues, to achieve the effect of convenient design and installation, reduced civil structure, and simplified design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

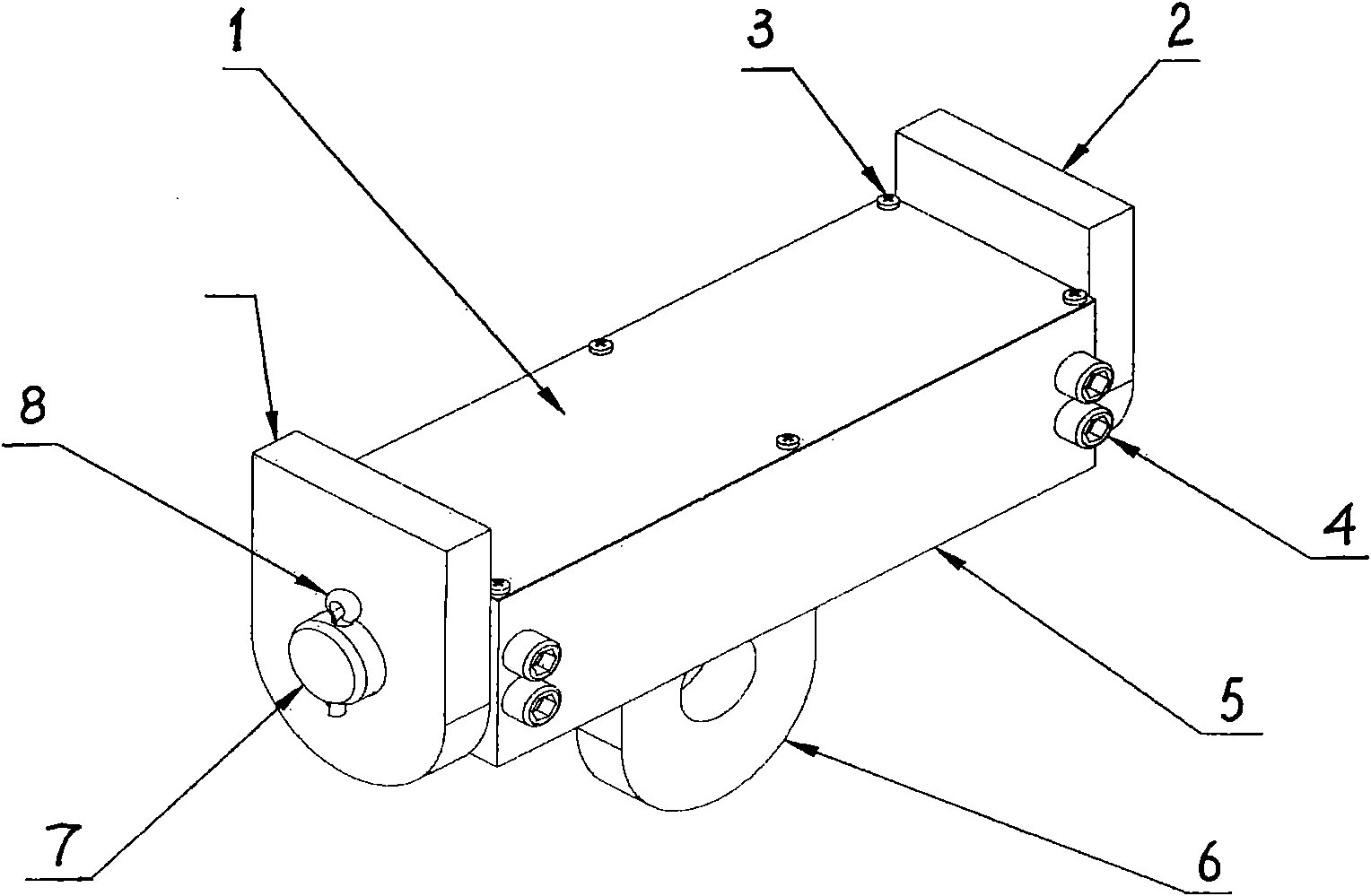

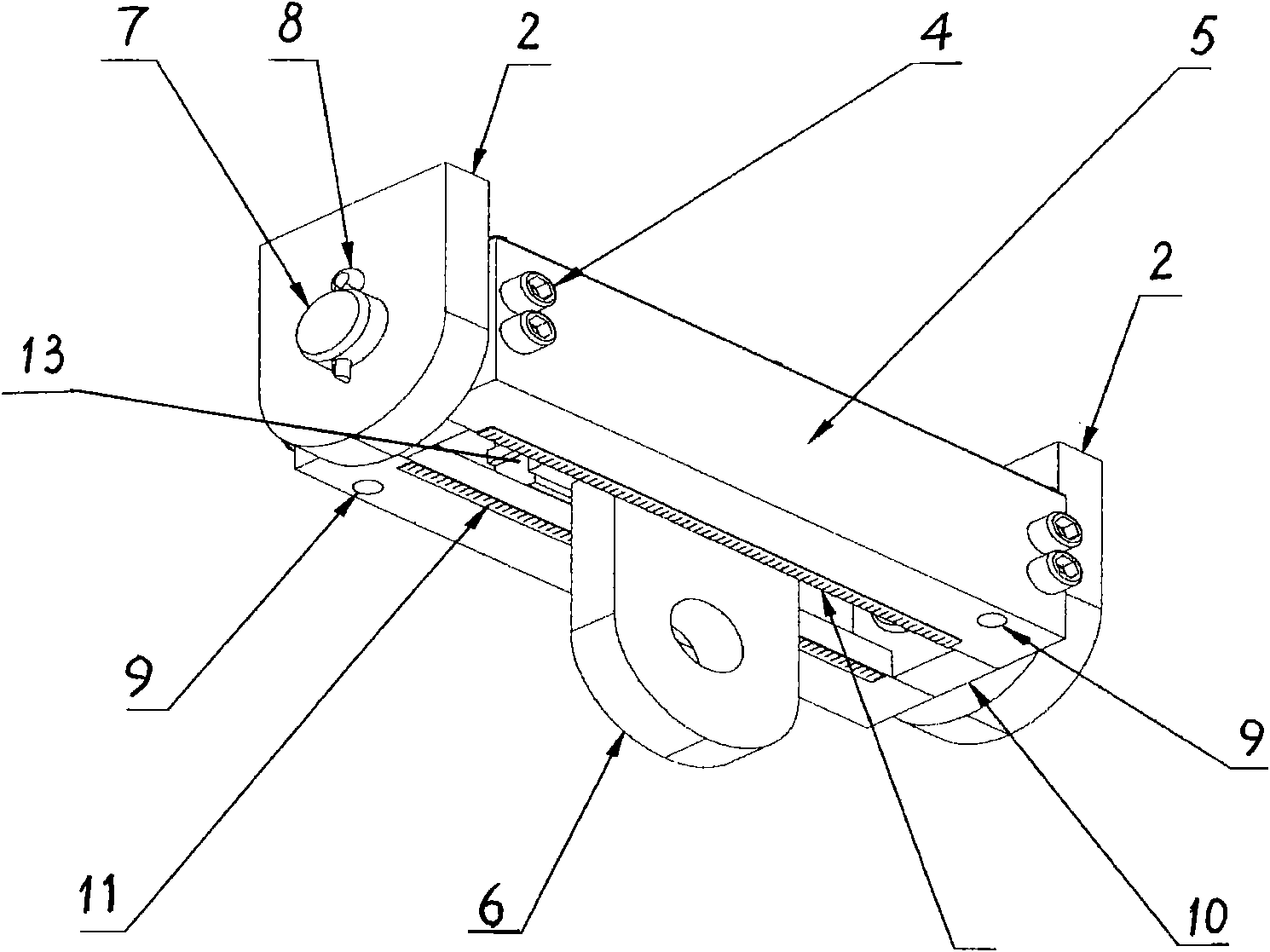

[0044] See attached figure 1 , 2 . This embodiment is a root part of a one-way hanger rolling bearing, which consists of a trolley guard plate 1, a welding side piece 2, a trolley fastening screw 3, a trolley fastening bolt 4, a trolley guide rail 5, a pin shaft 7, a pin 8, and a level bubble 9. The trolley guide rail end block 10, the trolley scale 11, the guide rail ball flat groove 12, and the first inner assembly 13 are jointly composed.

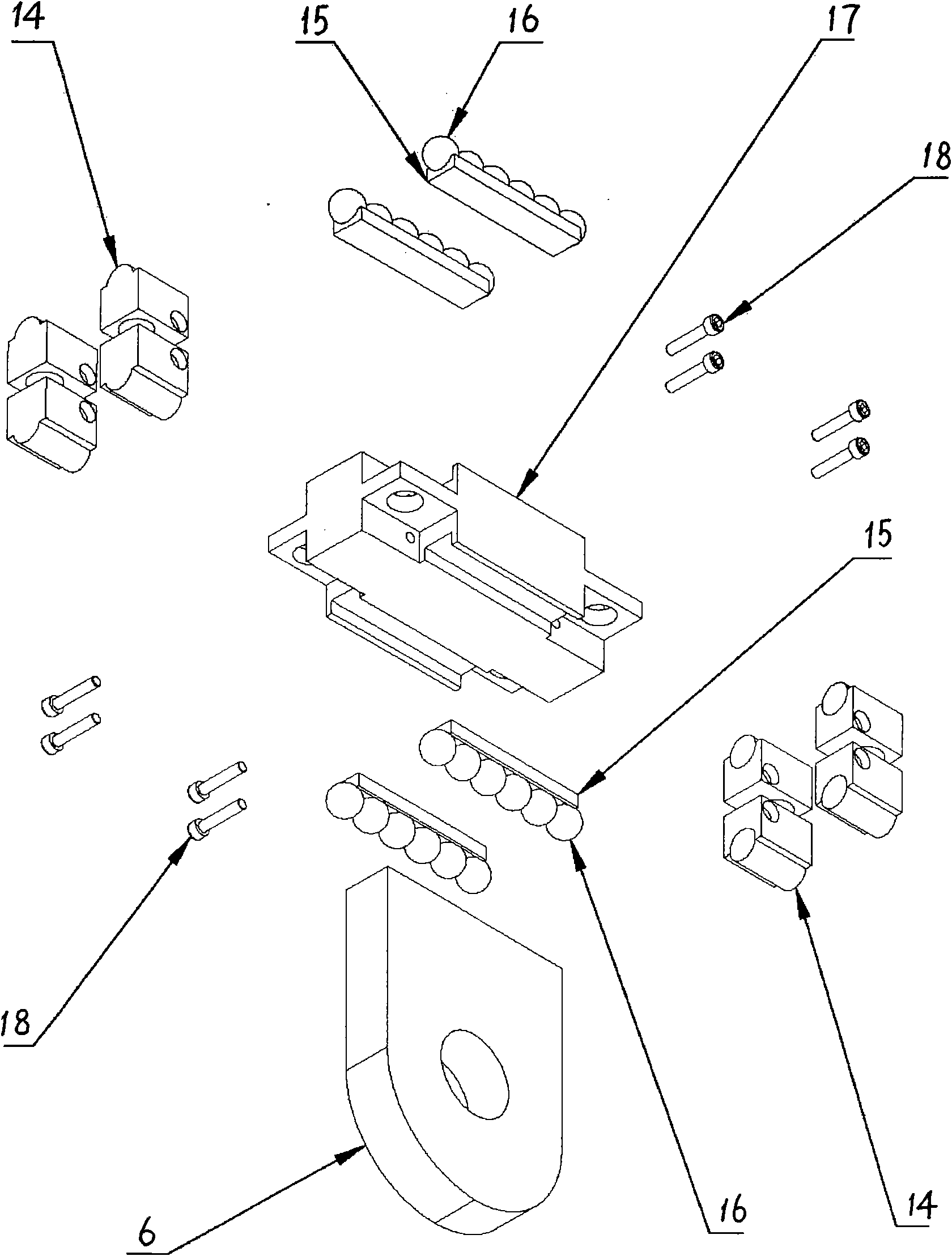

[0045] See attached image 3 . The first inner assembly 13 is composed of the eyelet welding piece 6, the trolley ball guide ring 14, the ball groove 15, the trolley ball 16, the trolley flat shaft 17, and the trolley second bolt 18. One end of the eyelet welding piece 6 is arc-shaped, and the other end is a plane end, and a round hole is opened in the arc-shaped end; the plane end of the eyelet welding piece 6 is welded on the bottom plate of the flat shaft 17 of the trolley, and the flat shaft 17 of the trolley is cross-shaped The...

Embodiment 2

[0052] See attached Figure 5 . This embodiment is a root component of a one-way bracket rolling bearing. In this embodiment, the basic structure of the root part of the rolling bearing of the support and hanger is the same as that of Embodiment 1, the difference lies in the welding sheet 6 with eyes and the guard plate 1 without trolley; in Embodiment 2, the root part of the rolling bearing of the support and hanger is turned up and down 180 degrees, Turn the side with the level bubble 9 and the trolley scale 11 upwards, no longer use the trolley guard plate 1, and weld the plane end of the welding side piece 2 to the lower civil structure; Its inner end is welded on the base plate of dolly flat shaft 17, and the outer end is provided with the band plate welded piece 19 of plate structure, and the face of band plate welded piece 19 is upwards, and plate structure can allow support tube support. The effect of this structural modification is to make the root part of the hange...

Embodiment 3

[0054] See attached Figure 6 , 7 . This embodiment is a two-way hanger rolling bearing root part, which consists of a second inner assembly 33, a cart upper guard plate 20, a cart fastening screw 21, a cart guide rail 22, a ball guide groove 23, and a cart guide rail end plate 24, cart fastening bolt 25, cart scale 26 form jointly. Wherein the second inner assembly 33 is composed of the first inner assembly 13, trolley guide rail 5, guide rail ball flat groove 12, trolley guide rail end block 10, level bubble 9, trolley scale 11, cart second bolt 27, cart ball guide Ring 28, cart ball groove 29, cart ball 30, cart third bolt 31, cart ball guide ring fixed plate 32 form together;

[0055] See attached Figure 9 , is part of the structure of the second inner assembly 33, wherein the structure of the first inner assembly 13 is the same as that of embodiment 1;

[0056] The trolley guide rail 5 has two left and right sides, and grooves are formed on the inner side thereof, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com