Anti-rotation device of rotary joint

A technology of rotary joints and adapters, applied in the direction of manufacturing converters, etc., can solve the problems of weakened fatigue strength of fixed joints, large rotational frictional resistance, shortened service life, etc., and achieves the effects of compact structure, reliable operation and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

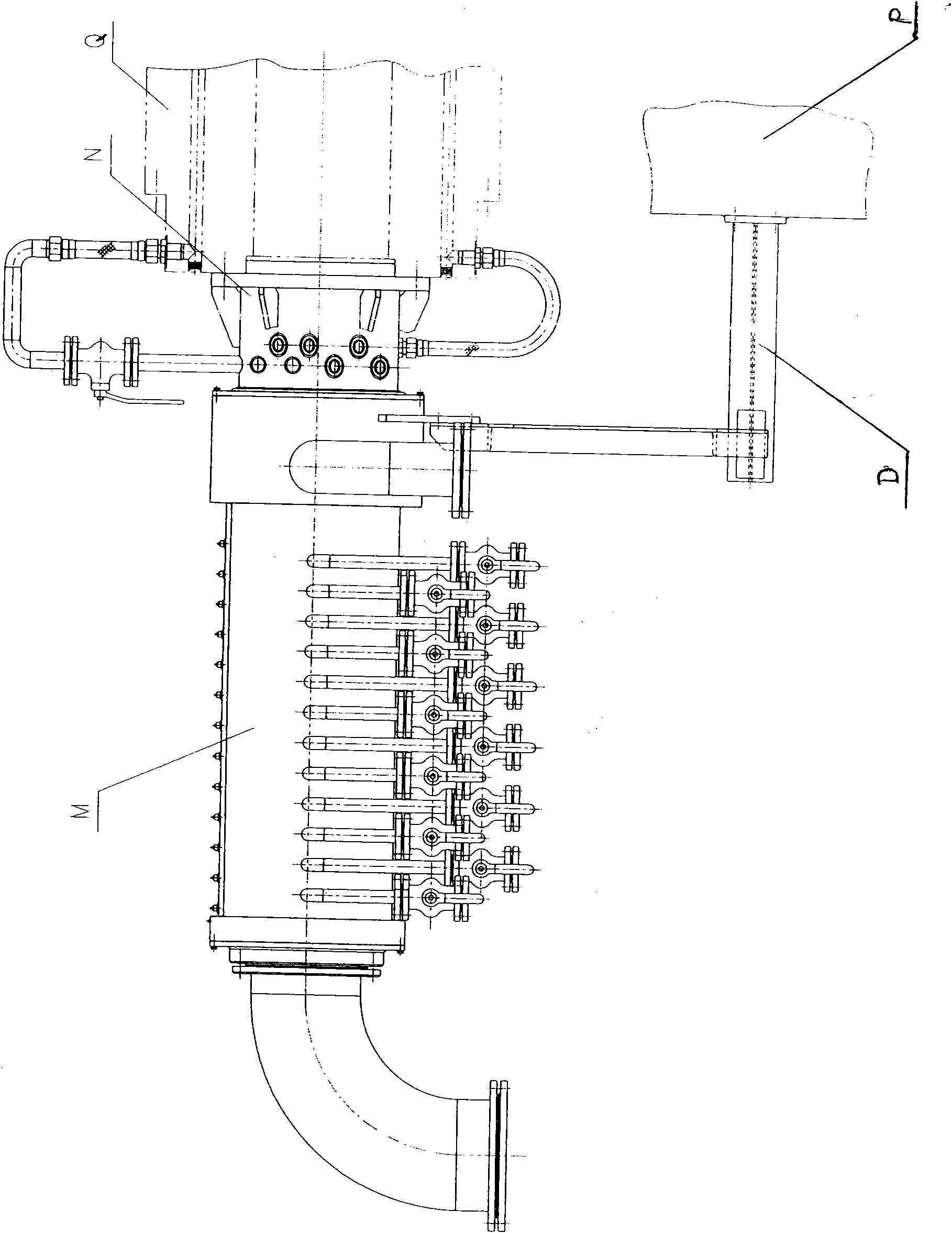

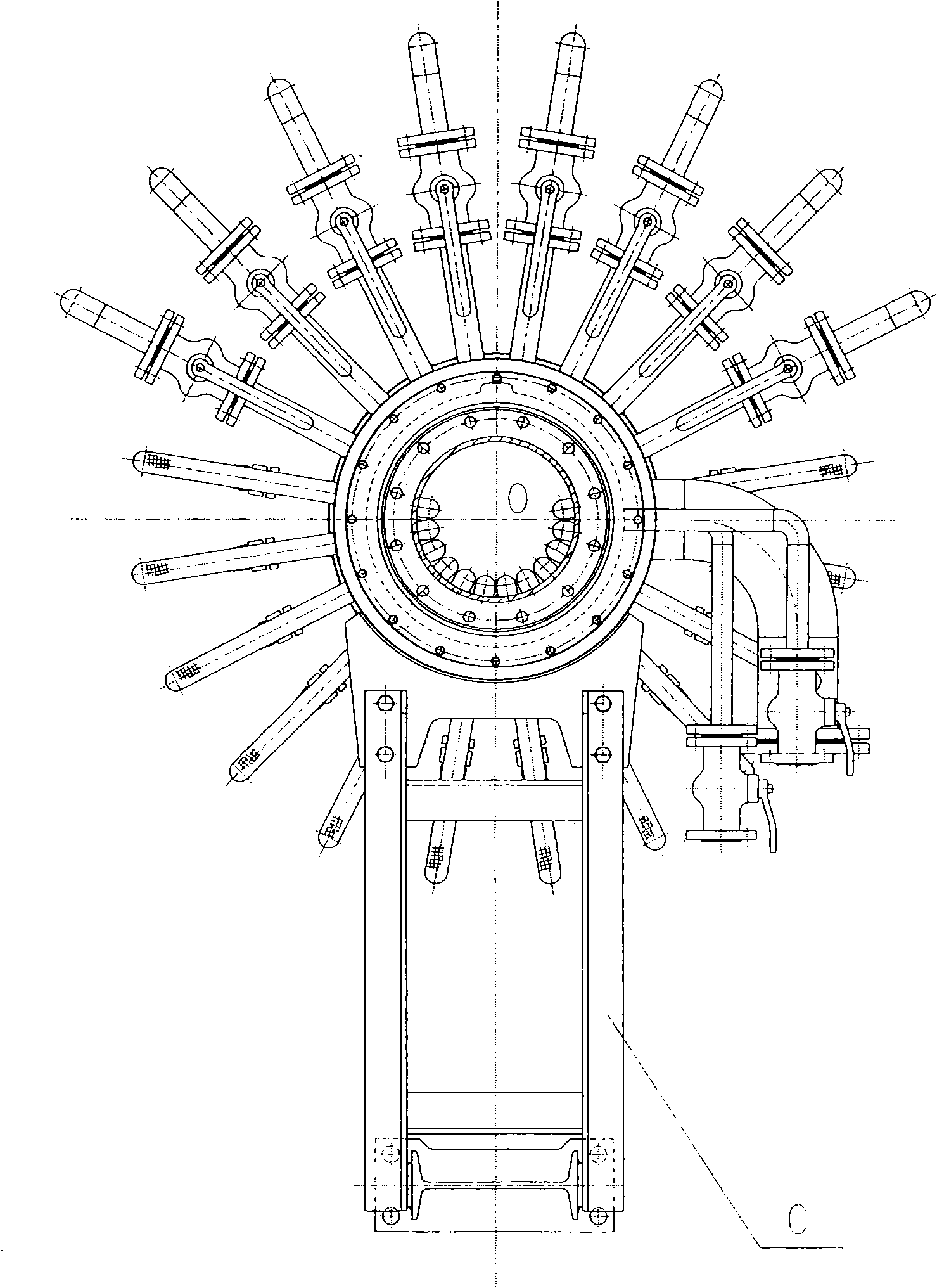

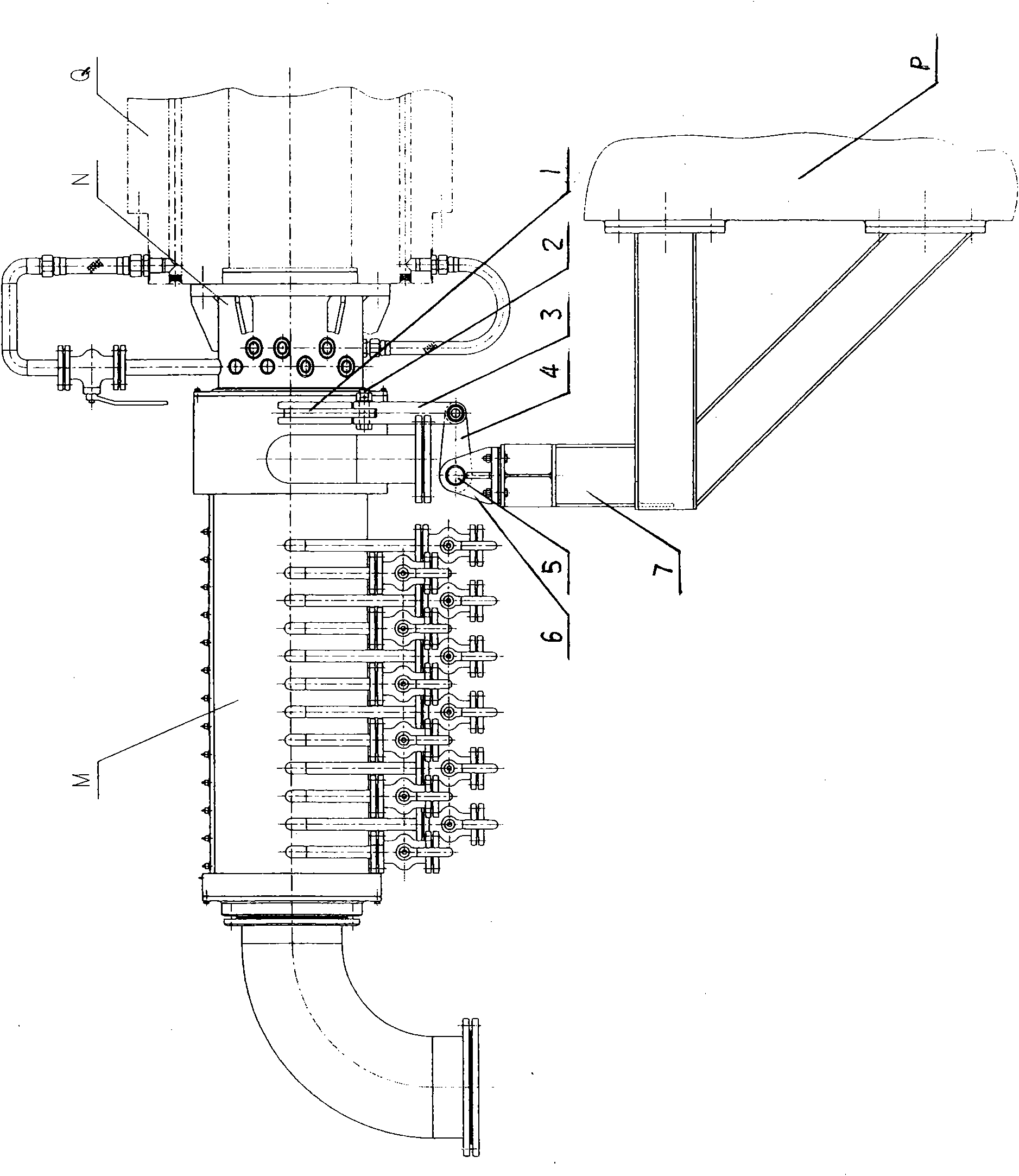

[0012] Attached below Figure 3-4 The specific embodiments of the present invention are further described:

[0013] The fixed plate 1 is fixed or welded to the adapter jacket M, one end of the connecting rod 3 is hinged with the fixed plate 1 by the pin 2; the other end of the connecting rod 3 is hinged with the crank 4 by the pin 2; one end of the crank 4 is hinged with the connecting rod 3 Use pin 2 to hinge, the other end of crank 4 is fixed or welded to torsion bar 5, the two ends of torsion bar 5 are respectively sleeved in the holes of support 6, support 6 and support 7 are connected by bolts, support 7 is bolted It is fixed on the bearing seat P of the converter. When one end of the connecting rod 3 is hinged with the fixed plate 1 with the pin 2, the axial direction of the pin 2 is parallel to the rotation axis of the rotary joint N, and the other end of the connecting rod 3 is hinged with the crank 4 with the pin 2 The axial direction of 2 is perpendicular to the N axis of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com