Design method for crack control crack of overlong concrete frame structure

A design method and technology of frame structure, applied in the direction of building structure, construction, etc., can solve the problems of increased lateral stiffness of frame column, increased additional force, increased material consumption, etc.

Inactive Publication Date: 2011-01-12

NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG +1

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, after the cross-sectional size is enlarged, the lateral stiffness of the frame column will further increase, resulting in an increase in the additional force... After all, it is still impossible to solve the contradiction of calculation

In the end, the designers had no choice but to give up the complicated calculations, but added reinforcements as much as possible, which not only increased the consumption of materials, but also failed to control the cracks within the maximum crack width limit

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

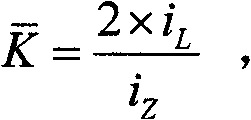

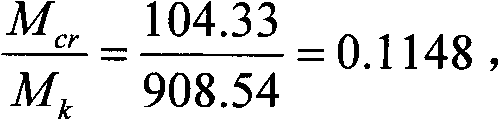

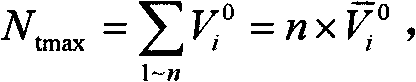

The invention discloses a design method for crack control crack of an overlong concrete frame structure, concretely comprising the following steps of: determining the value of a comprehensive calculation temperature difference sigma delta t: determining the value of a season temperature difference delta t1 and determining the value of an equivalent temperature difference delta t2 of the contraction distortion of the concrete; calculating the additional elastoplasticity force of the concrete frame: introducing the elastoplasticity rigidity reduction coefficient beta' and determining the upper and lower limits of beta', calculating the elastoplasticity sideway movement resisting rigidity of an intermediate column of the frame, calculating the column top shearing force value of an intermediate column in the frame column line, and calculating the column top shearing force value Vn0 of an (n) column on the end part of the frame; and designing and rechecking the sections of the beam and column of the overlong frame: designing the section of the frame beam and rechecking the frame column. The design method has simple solving process and simple and clear design process, and cannot only save materials, but also can control the width of the crack in a maximal crack width limitate value, thereby bringing convenience to the design and the construction.

Description

technical field The invention relates to the field of civil engineering, in particular to a design method for crack control of an ultra-long concrete frame structure. Background technique With the increasing scale of urban construction, the area of single public buildings is getting larger and larger, and the length of single frame structures is also getting longer and longer, mostly between 100m and 200m, or even longer. It has long been stipulated in the "Code for Design of Concrete Structures" (GB50010-2002) (hereinafter referred to as the "Code") that when the concrete frame structure exceeds 55m (35m for the open-air cast-in-place frame), it must be extended to its length. However, in actual engineering, due to the use and structure, it is often inappropriate or not allowed to set up joints along the length of the building to divide and disconnect. At this time, the concrete frame is called an ultra-long concrete frame. For this ultra-long concrete frame structure, i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04B1/19E04B1/20

Inventor 焦彬如郭昌生卓开云余少群李水明

Owner NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com