Vertical efficient water washer

A water-washing, high-efficiency technology for mechanical cleaning, high-pressure cleaning, textiles and papermaking, etc., which can solve the problems of large occupation area, waste of water, and high cost of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

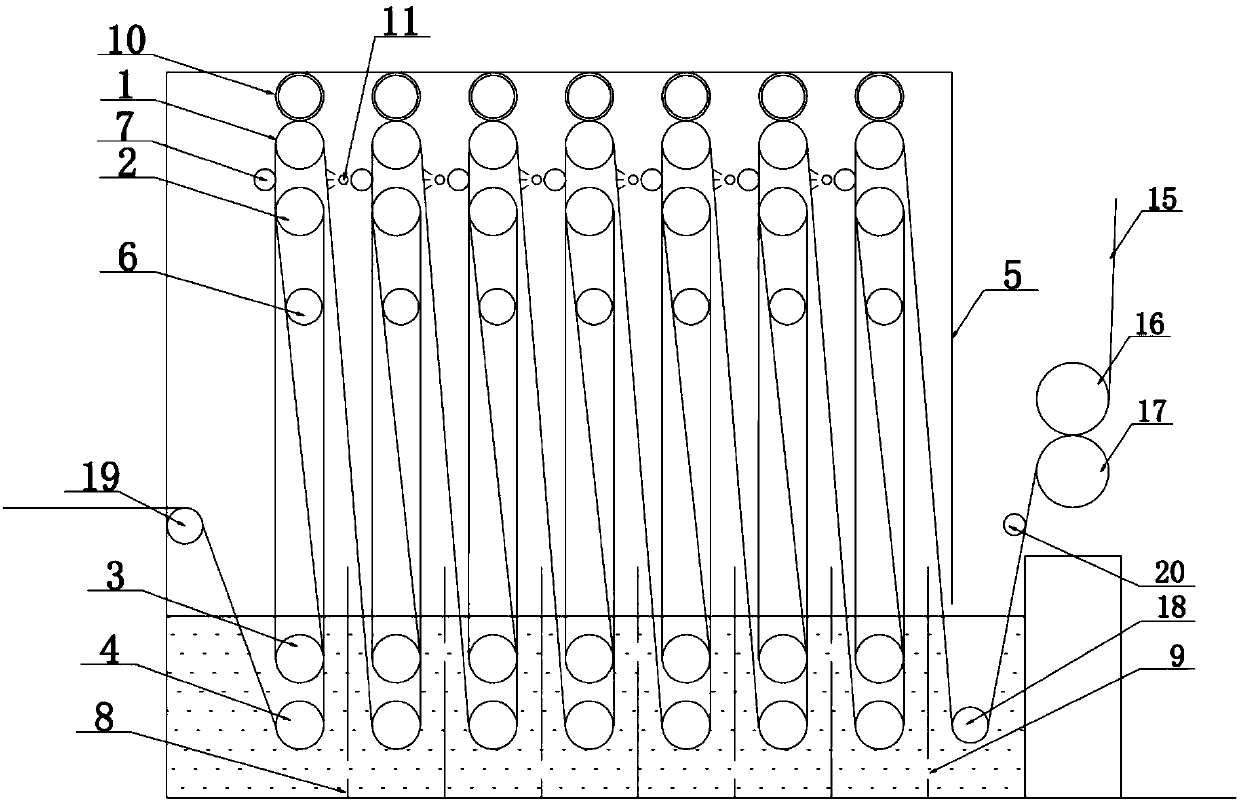

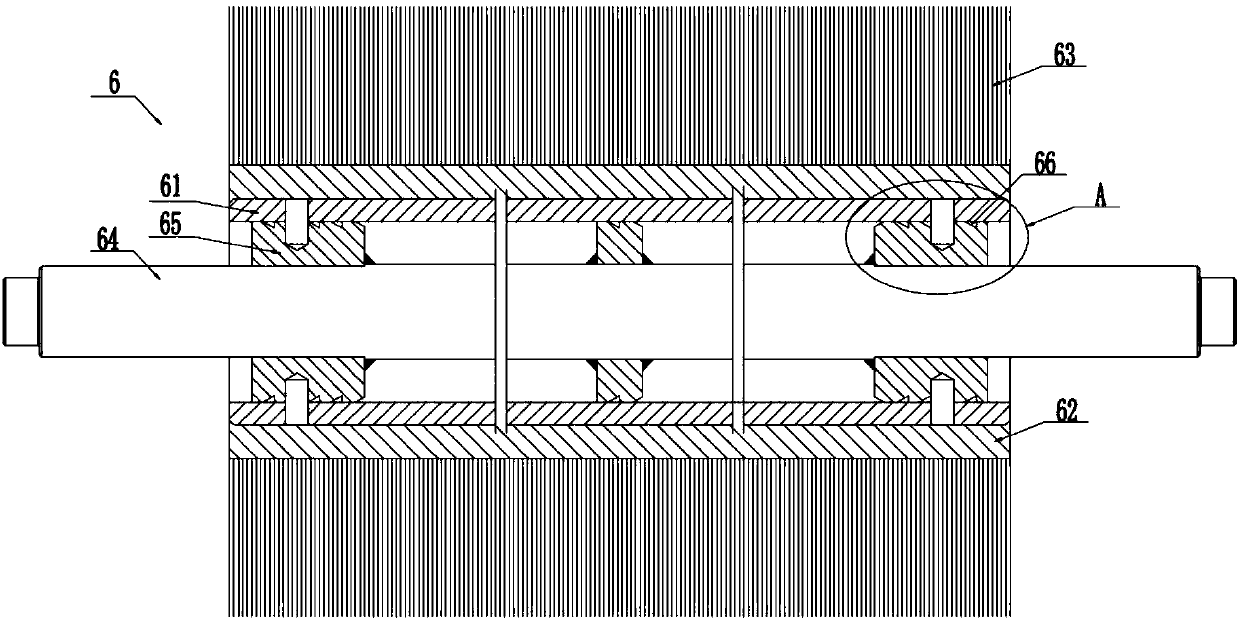

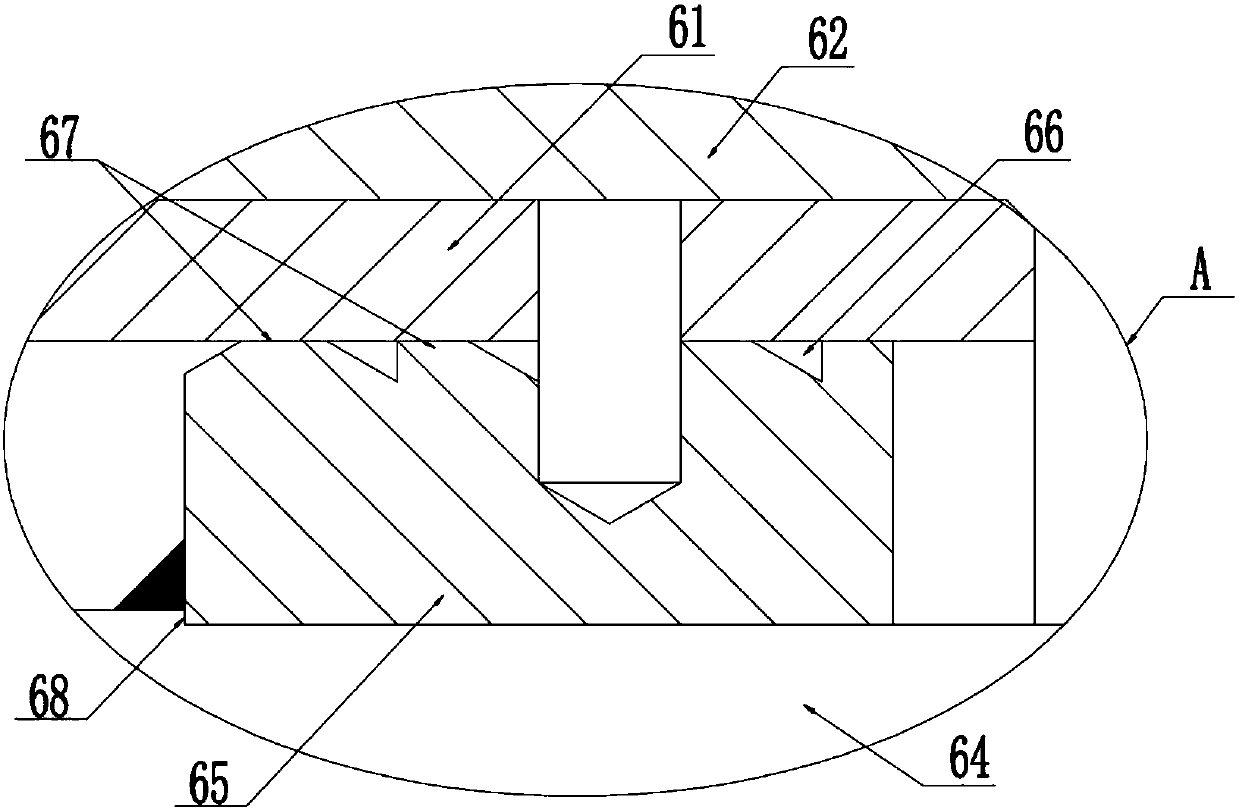

[0045] As shown in Figure 1- Figure 8 As shown, a vertical high-efficiency water washing machine includes a rectangular box body 5, and at least two groups of cloth guide assemblies are arranged in the rectangular box body, and the cloth guide assembly includes a first cloth guide roller 1 arranged from top to bottom. , the second cloth guide roller 2, the third cloth guide roller 3 and the fourth cloth guide roller 4, the cloth is sequentially guided through the fourth cloth guide roller, the second cloth guide roller, the third cloth guide roller and the first cloth guide roller Roller, guiding the fourth cloth guide roller of the secondary cloth guide assembly, a brush roller 6 is arranged between the second cloth guide roller and the third cloth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com