Pull-rod modularized guide vane type diagonal flow pump

A modular and tie-rod technology, which is applied in the direction of non-variable pumps, non-volume pumps, and rotary non-variable pumps, can solve the problems of cumbersome processing, troublesome installation and disassembly, inconvenient maintenance and testing, etc. Achieve the effects of reducing labor, convenient processing, and reducing refraction deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

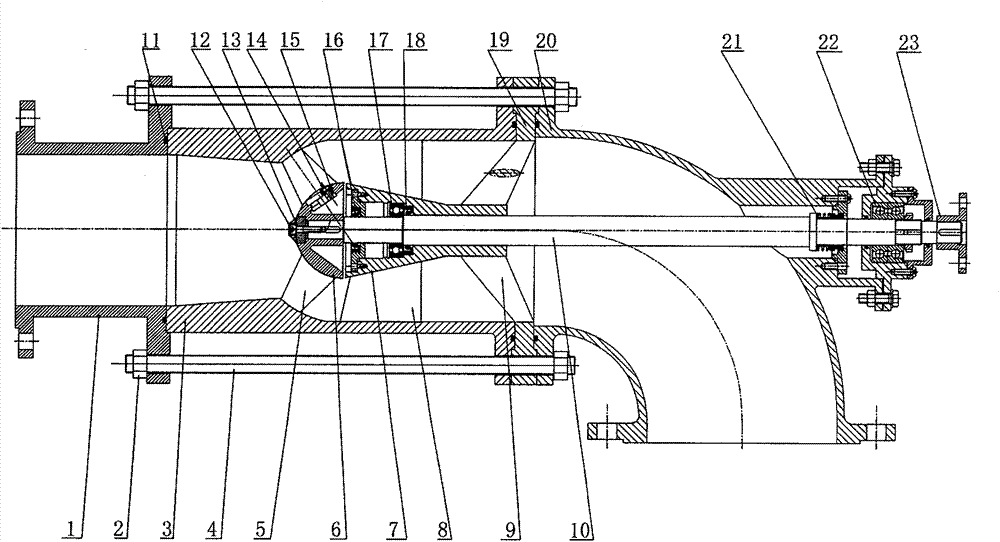

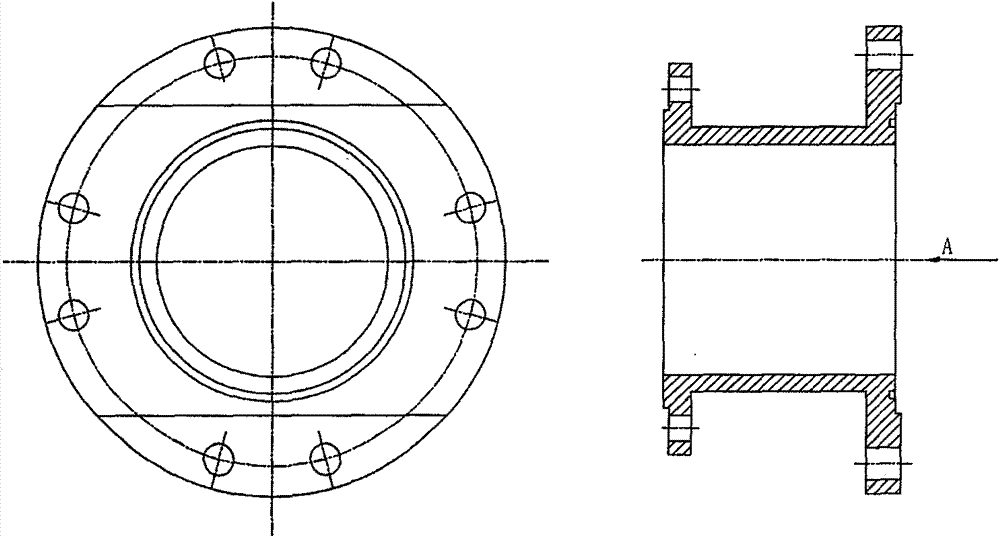

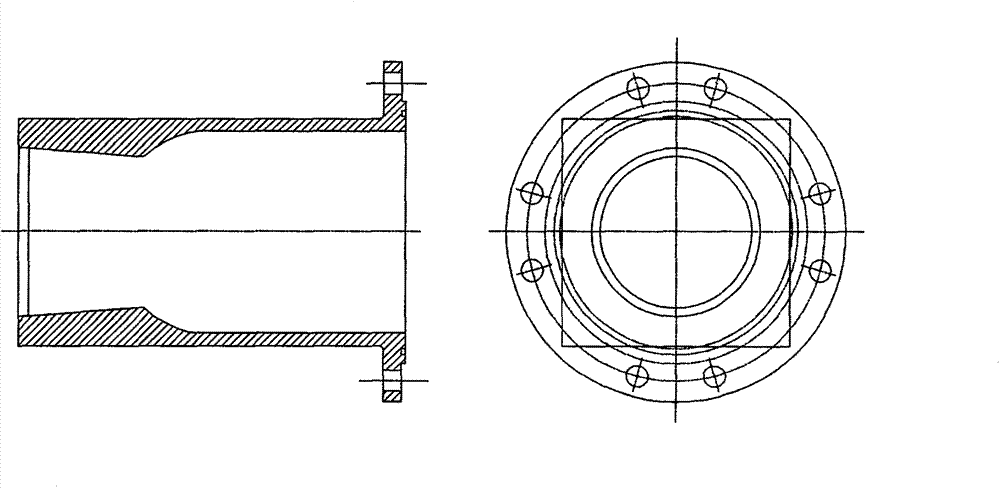

[0018] Depend on figure 1 It can be seen that the oblique flow pump consists of the connecting section of the outer cylinder and the inlet pipe (1), the large hex nut (2) for the bolted structure, the square outer cylinder (3), the pull rod (4), the impeller blade (5), the impeller hub ( 6), guide vane hub (7), guide vane blades (8), streamlined ribs (9), pump shaft (10), O-ring (11), water guide cone (12), screws (13), Slotted countersunk head screw (14), pressure plate (15), J-type frameless oil seal (16) (18), elbow section (20), deep groove ball bearing (17), mechanical seal (21), angular contact Ball bearings (22) and couplings (23) and other components are made up. Fix the impeller blade (5) on the impeller hub (6) through the pressure plate (15) and the slotted countersunk head screw (14) to form the impeller; One end is wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com