Test system for vertical compression power generation module

A technology of power generation module and test system, applied in electric power measurement through current/voltage, multi-tester circuit, generator/motor, etc., can solve the problem of high frequency, small pressure value, structure and material process optimization and provide effective reference, etc. problem, to achieve the effect of high test accuracy, convenient operation and wide test range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

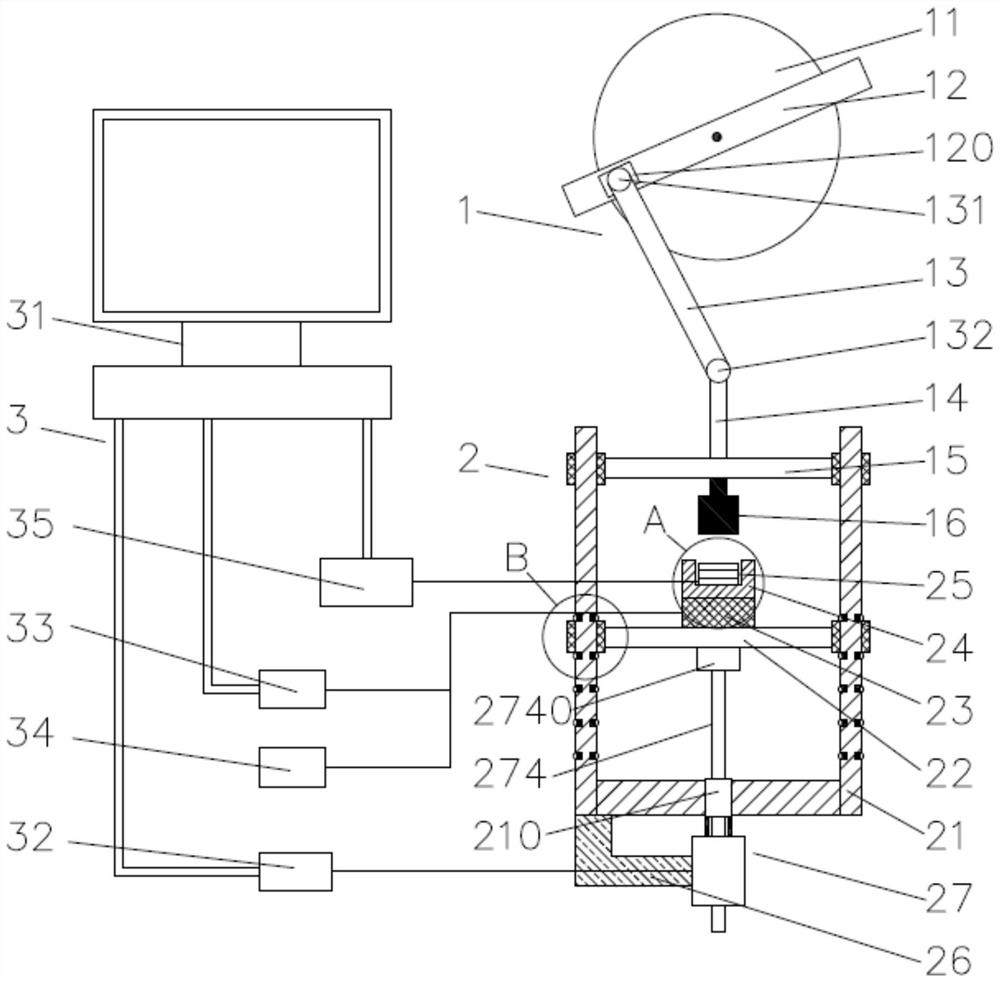

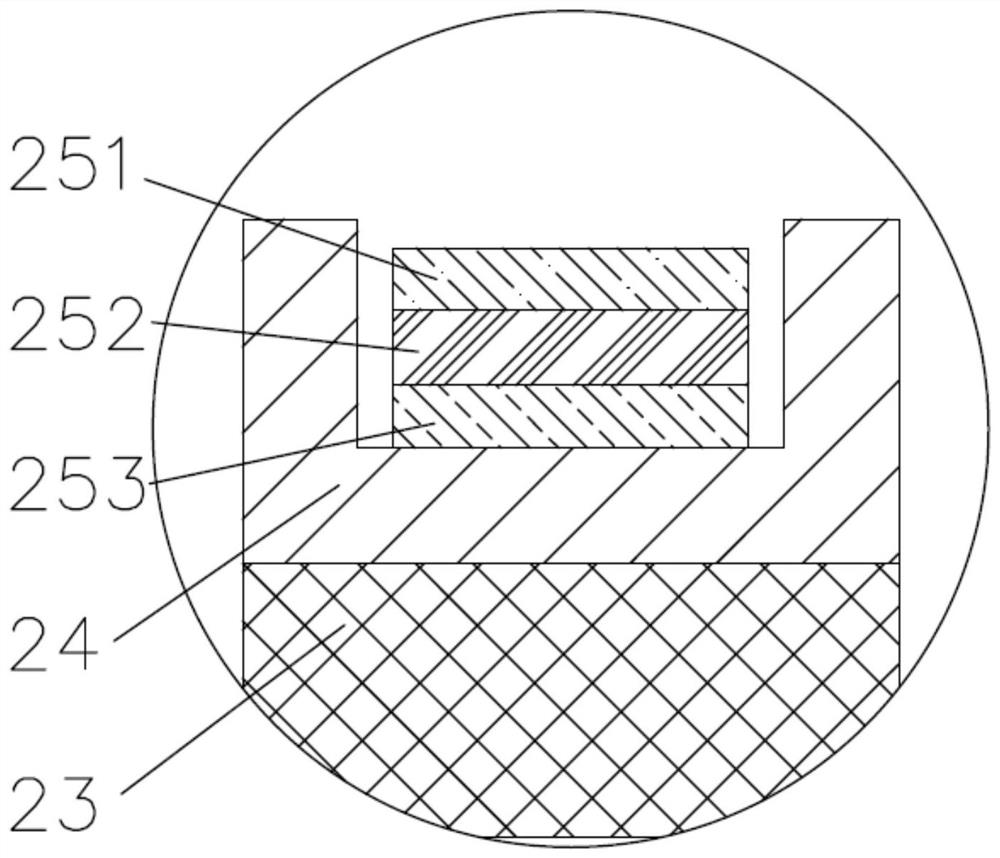

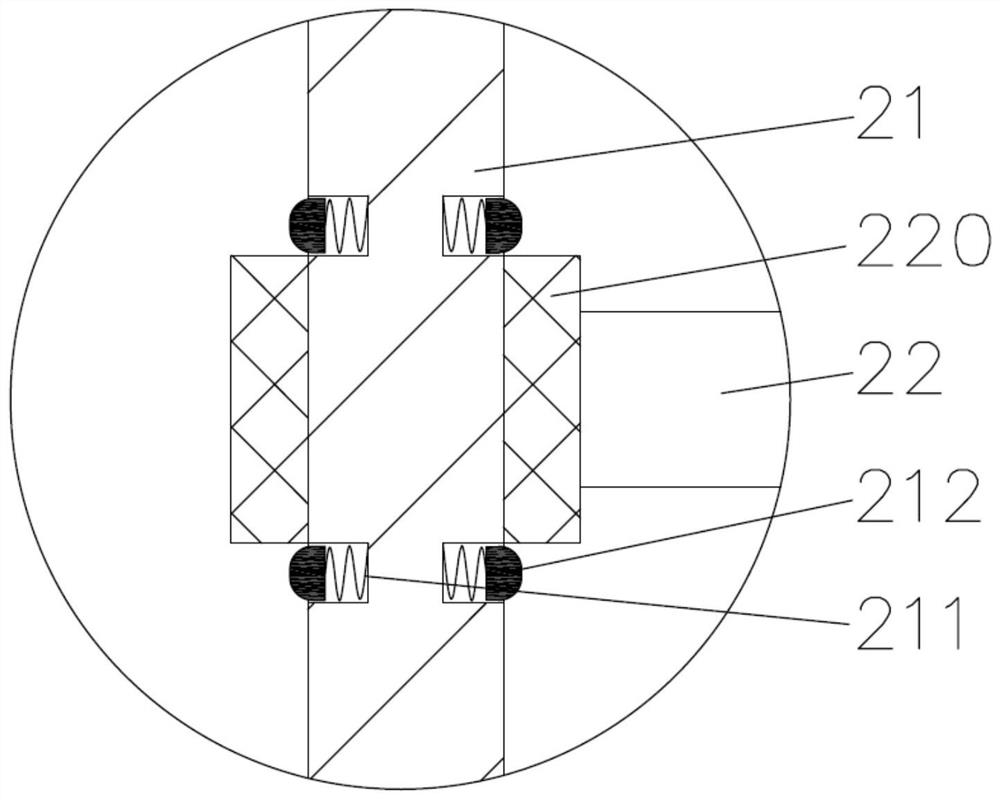

[0031] like Figure 1 ~ 4As shown, a vertical pressure power generation module test system, comprising reciprocating press assembly 1, lifting test assembly 2, and monitoring device 3; lifting test assembly 2 is disposed at the lower end of the reciprocating stamping assembly 1; reciprocating press assembly 1 including rotation The disk 11, the fixing rod 12, the first connecting rod 13, the second connecting rod 14, the first slip plate 15, and the impact hammer 16, the rotary disk 11 is fixedly disposed with a fixing bar 12 and the center of the fixed bar 12 and the rotary disk 11 The center is the same point, and the rotating disk 11 is left away from one side end surface of the fixing rod 12 to set a drive motor (the axis of the output shaft of the drive motor is common in the axis of the rotary disk 11, and the figure is not drawn, according to the art in the art Set), used to control the rotary disc 11, the drive motor is electrically connected to the monitoring device 3; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com