Petroleum pipeline support with adjustment function

A technology for oil pipelines and pipeline supports, applied in the direction of pipeline supports, hoses, pipes, etc., can solve the problems of inconvenient pipeline erection and installation, oil pipeline support rupture, oil pipeline support without lifting and horizontal adjustment, etc., to ensure smooth flow, The effect of preventing breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

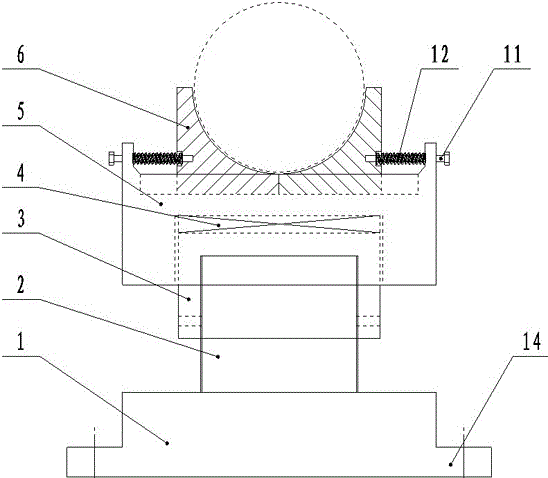

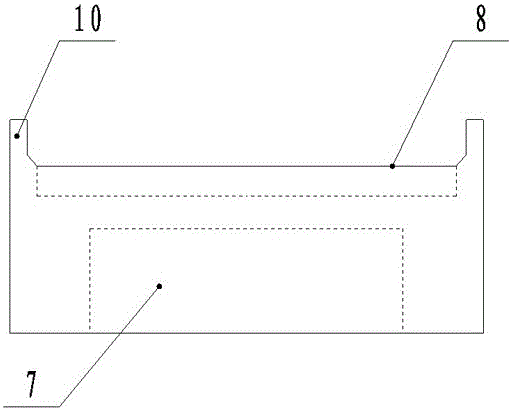

[0022] like Figure 1-4 As shown in the figure, an oil pipeline support with adjustment function of the present invention includes a pipeline support base 1, a lifting screw 2, a lifting nut 3, a pressure bearing 4, a support seat 5 and a pipeline limit block 6, and the lifting screw 2 is provided with The pipeline support base 1 plays a general supporting role for the oil pipeline support, the lifting nut 3 is threadedly sleeved on the lifting screw 2, the lower end of the support base 5 is provided with a supporting groove 7, and the supporting groove 7 is sleeved on the lifting nut 3 On the top, a pressure bearing 4 is arranged between the support groove 7 and the lifting nut 3, and the upper end of the support base 5 is provided with a mounting chute 8 for the pipeline limit block 6, and the two pipe limit blocks 6 are symmetrically arranged on the slide. in slot 8. The bottom of the pipe support base 1 is provided with a bolt fixing table 14 .

[0023] When in use, a bo...

Embodiment 2

[0025] like Figure 4 As shown, the present invention is an oil pipeline support with adjustment function. On the basis of Embodiment 1, the lifting nut 3 is provided with a lifting adjustment hole 9 . The support base 1 is moved up and down by rotating the lifting nut 3. When rotating the lifting nut 3, in order to rotate the lifting nut 3 easily, the lifting nut 3 can be easily rotated by inserting a steel pipe or steel bar into the lifting adjusting hole 9.

Embodiment 3

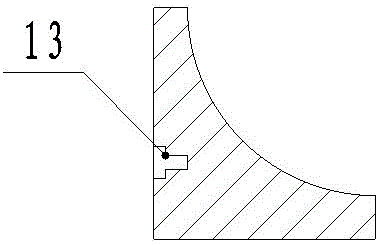

[0027] like image 3 As shown, the present invention is an oil pipeline support with an adjustment function. On the basis of Embodiment 1, a limit block adjustment table 10 is arranged on both sides of the support base 5, and a horizontal screw hole is arranged on the limit block adjustment table 10. The screw hole A limit block adjustment column 11 is arranged inside, and the limit block adjustment column 11 can be rotated in the screw hole. The outer end of the limit block adjustment column 11 is also provided with a nut clamped by a handle, and the limit block adjustment column 11 is adjusted The pipe limit block 6 moves in the chute 8 . A buffer spring 12 is sleeved on the limit block adjustment column 11 , and the two ends of the buffer spring 12 are respectively pressed on the limit block adjustment platform 10 and the pipeline limit block 6 . A T-shaped hole 13 is provided on the pipe limit block 6 corresponding to the limit block adjustment column 11 , the buffer spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com