Tool for drilling inclined hole in circular plate-shaped part

A technology for drilling oblique holes and circular ring plates, which is applied in the field of machining equipment and can solve problems such as poor angle control and poor clamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is specifically described below with examples.

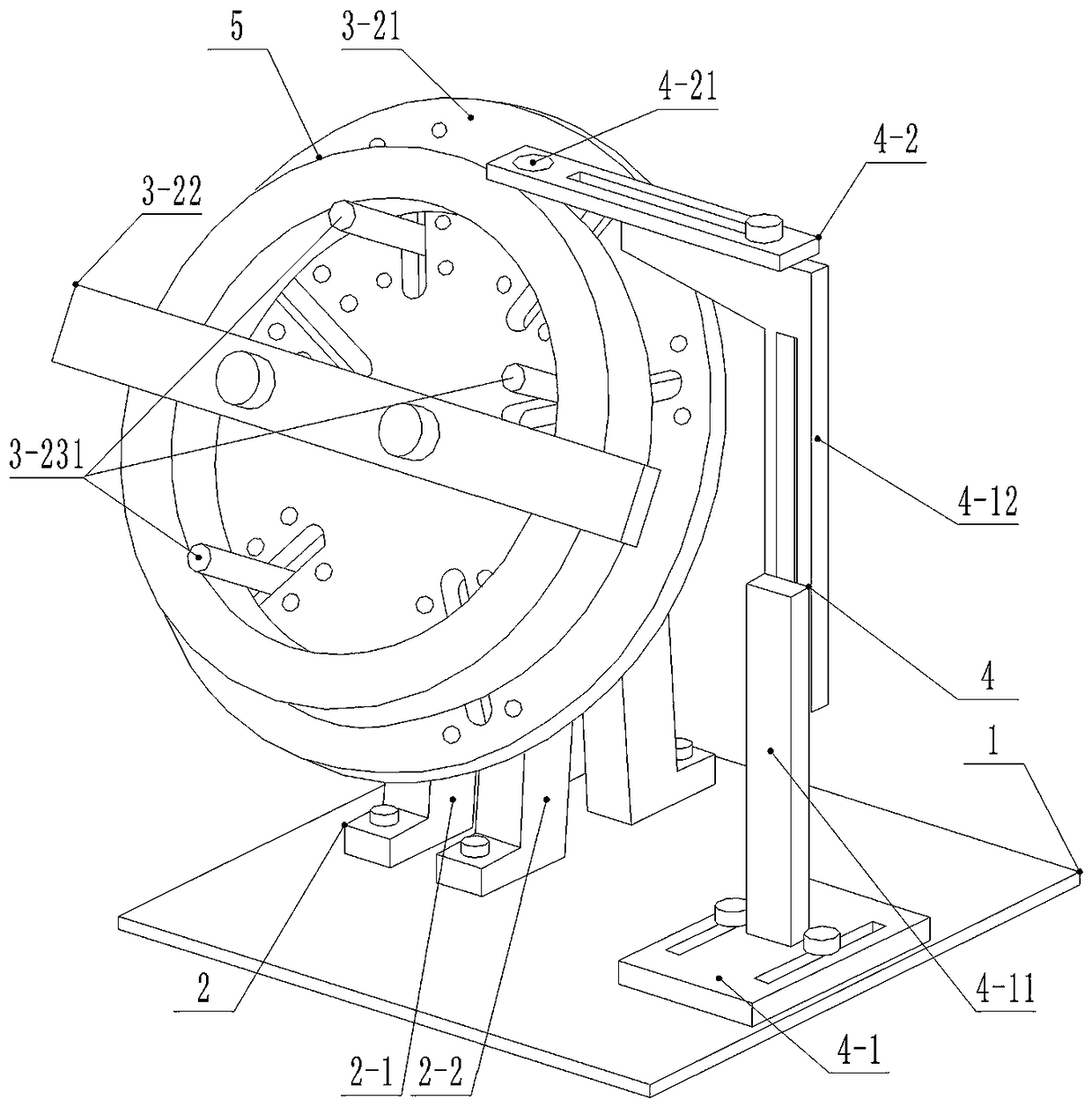

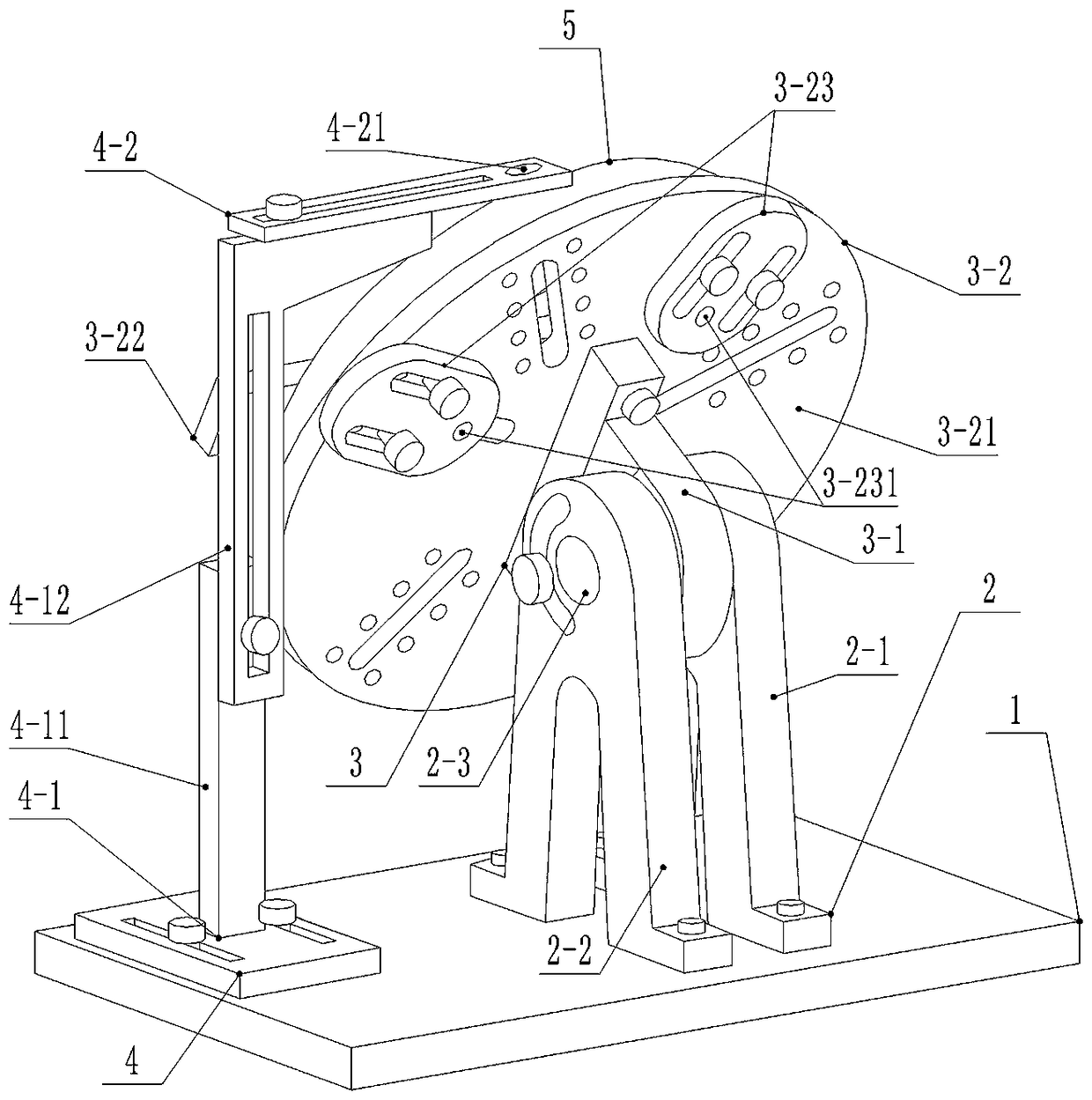

[0030] refer to Figure 1-Figure 5 , a tool for drilling inclined holes in circular plate-shaped parts, including a workbench 1, a support seat 2 installed on the workbench 1, and a support plate 3,

[0031] The support base 2 is composed of a left support arm 2-1 and a right support arm 2-2, the bottoms of the left support arm 2-1 and the right support arm 2-2 are fixed on the workbench 1, the two support arms are arranged at intervals, and the top passes through The horizontally arranged rotating shafts 2-3 are connected, and the tops of the two arms are each equipped with arc-shaped waist holes surrounding the rotating shafts 2-3,

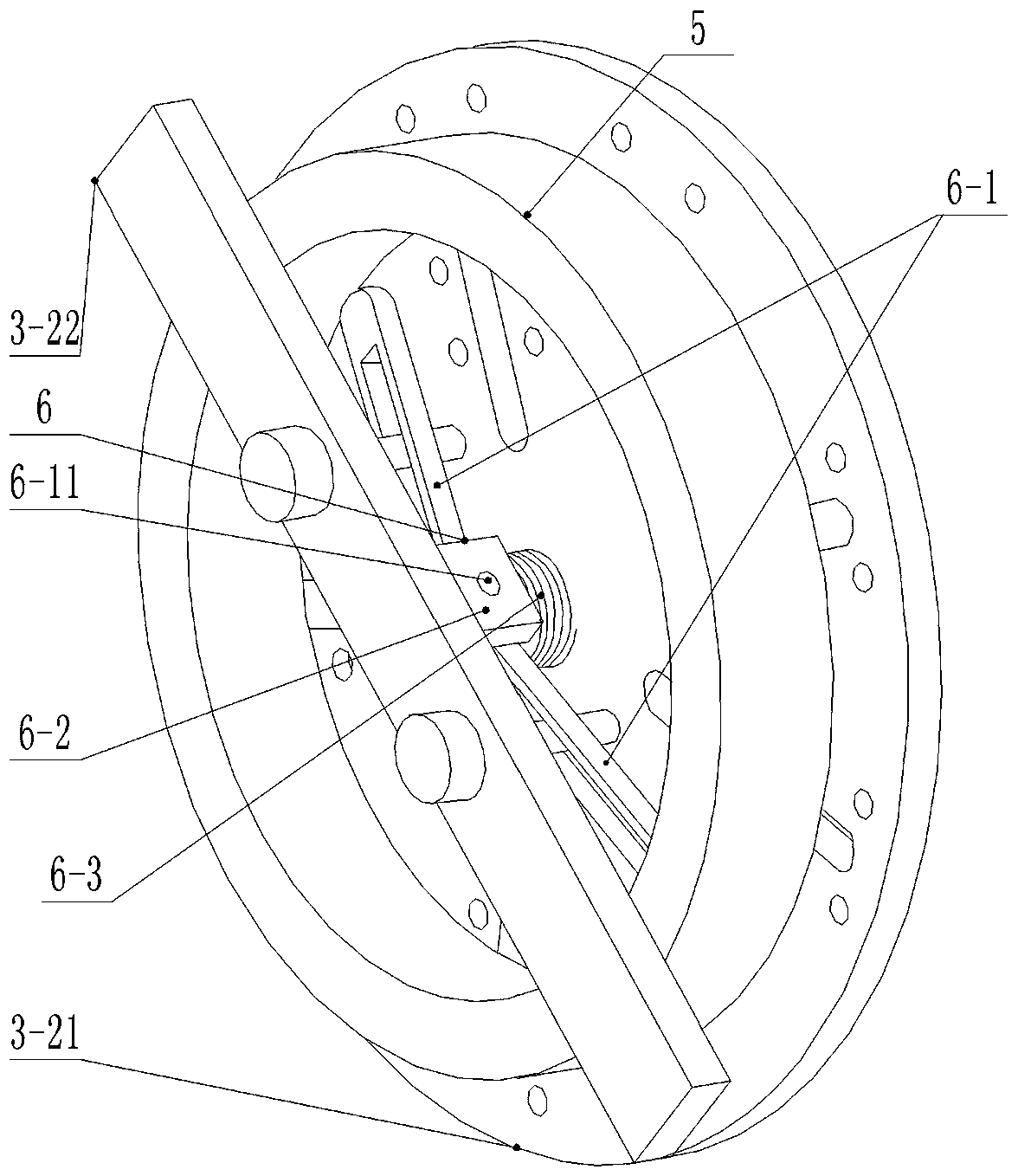

[0032] The support plate 3 includes a connecting portion 3-1 and a workpiece holder 3-2, and the workpiece holder 3-2 includes a base plate 3-21, a pressing plate 3-22 and a positioning pin plate 3-23,

[0033] The bottom plate 3-21 is provided with not less than thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com